Devices for coiling and unwinding hot-rolled rods

A bar and rolling technology, which is applied in the field of coiling and unwinding hot-rolled bar devices, can solve the problems of reduced durability, reduced productivity, frequent failures, etc., and achieve the effect of eliminating speed differences and maintaining constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The device for coiling and unwinding hot-rolled bars according to the invention can have different modifications and embodiments, and specific embodiments will be shown in the drawings and described in the detailed description. However, it should be understood that the present invention is not intended to be limited to these specific embodiments, but includes all modifications, equivalents and alternatives falling within the spirit and scope of the present invention.

[0045] Hereinafter, an apparatus for coiling and unwinding a hot-rolled bar according to the present invention will be described in detail with reference to the accompanying drawings.

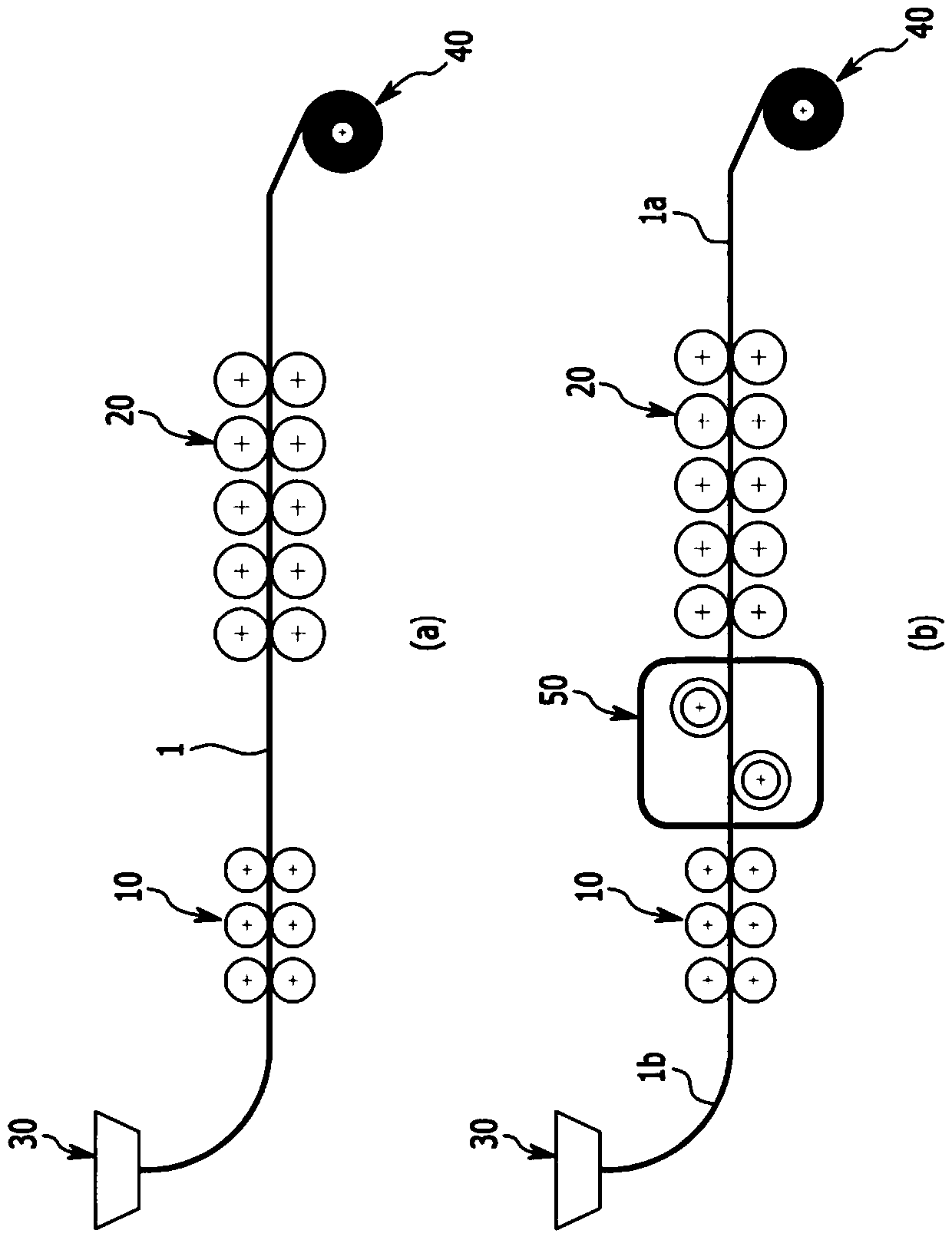

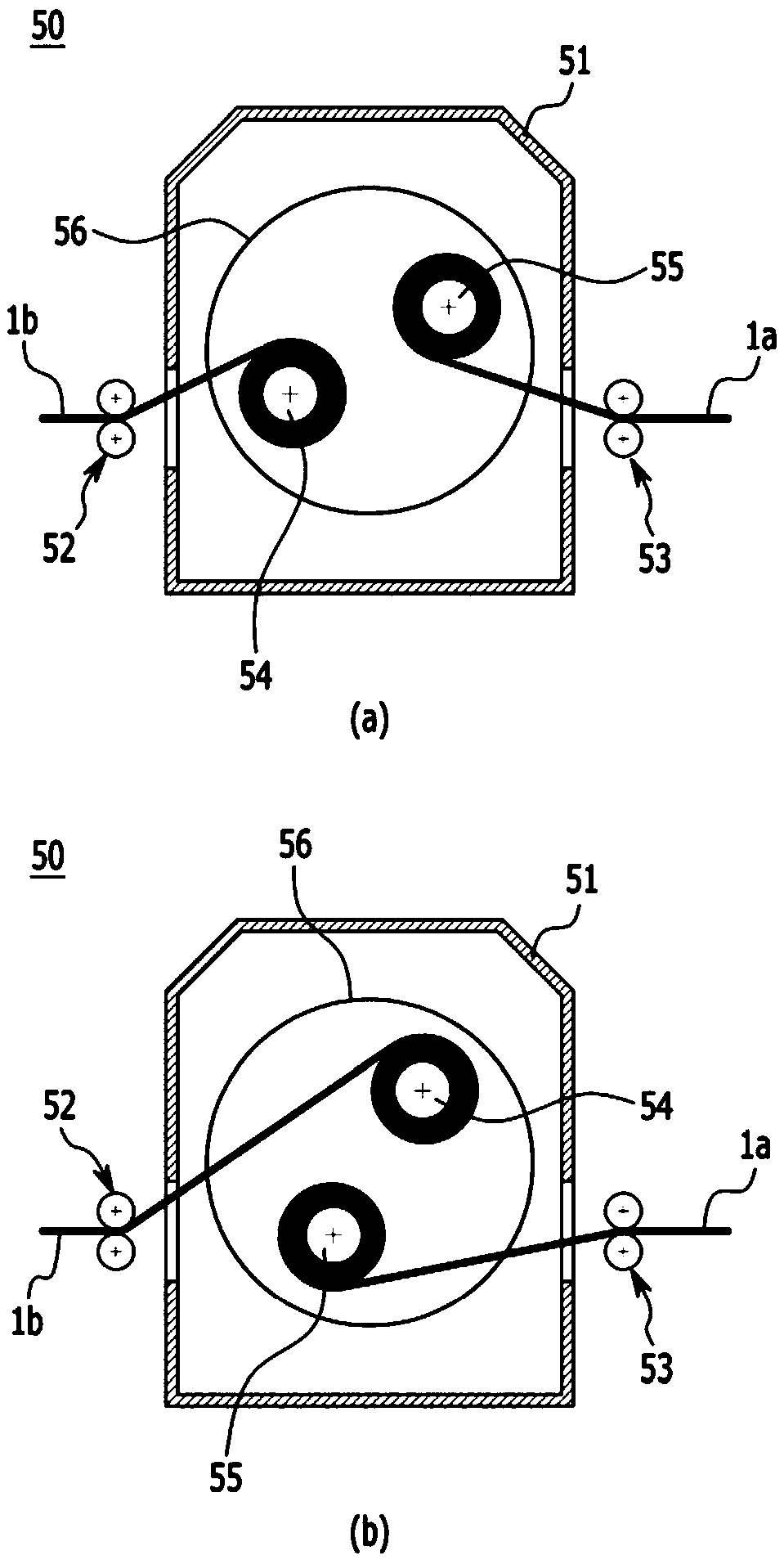

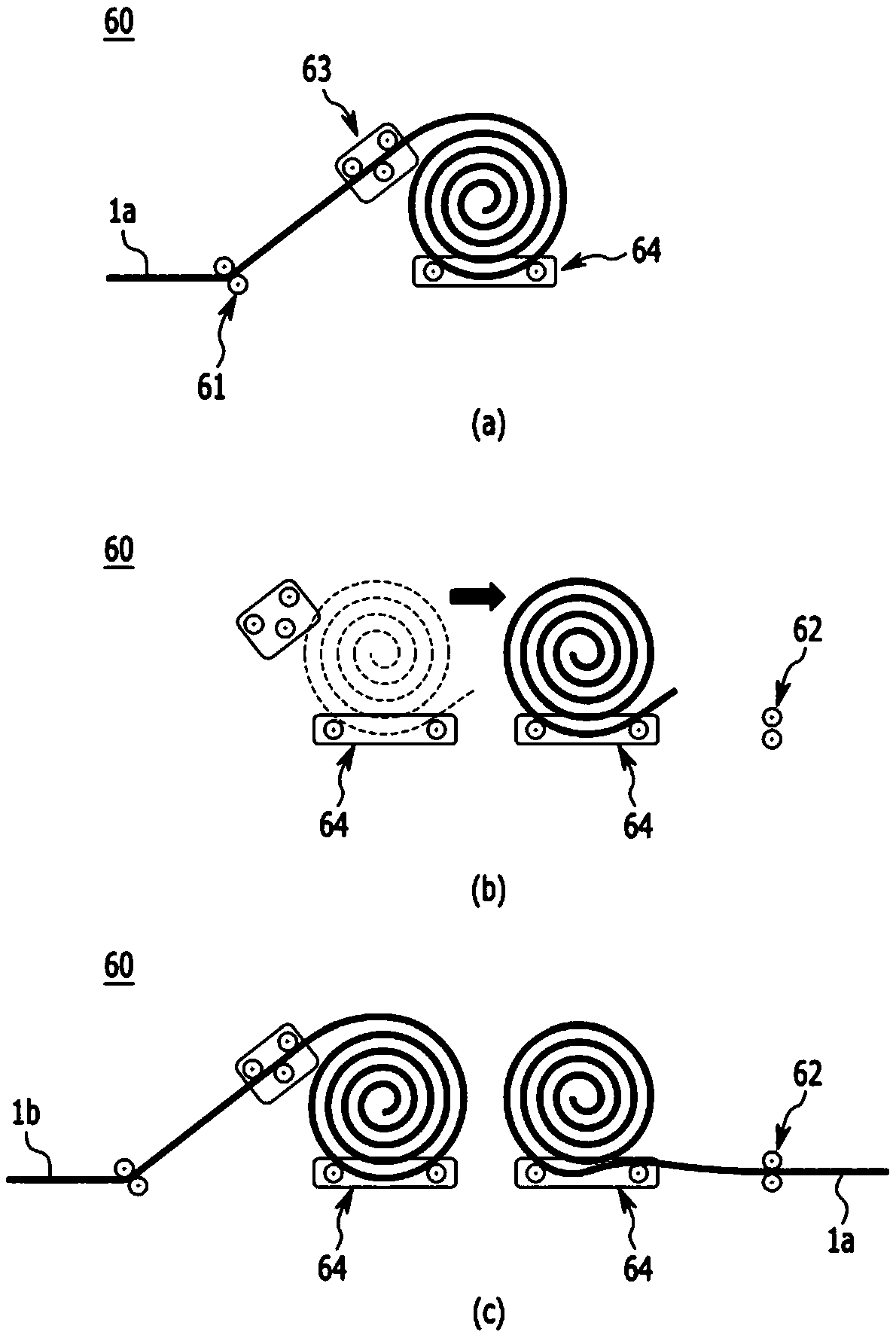

[0046] Figure 4 is a sectional view showing an apparatus for coiling and unwinding a hot-rolled bar according to a preferred embodiment of the present invention. Figure 5 In addition to showing hot-rolled bars, it also shows Figure 4 Apparatus for coiling and unwinding hot-rolled bars according to the invention shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com