Automatic polishing device for surface finishing of complex-curved-profile parts

A surface treatment, automatic polishing technology, used in grinding/polishing equipment, machine tools for surface polishing, machine tools suitable for grinding the edge of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

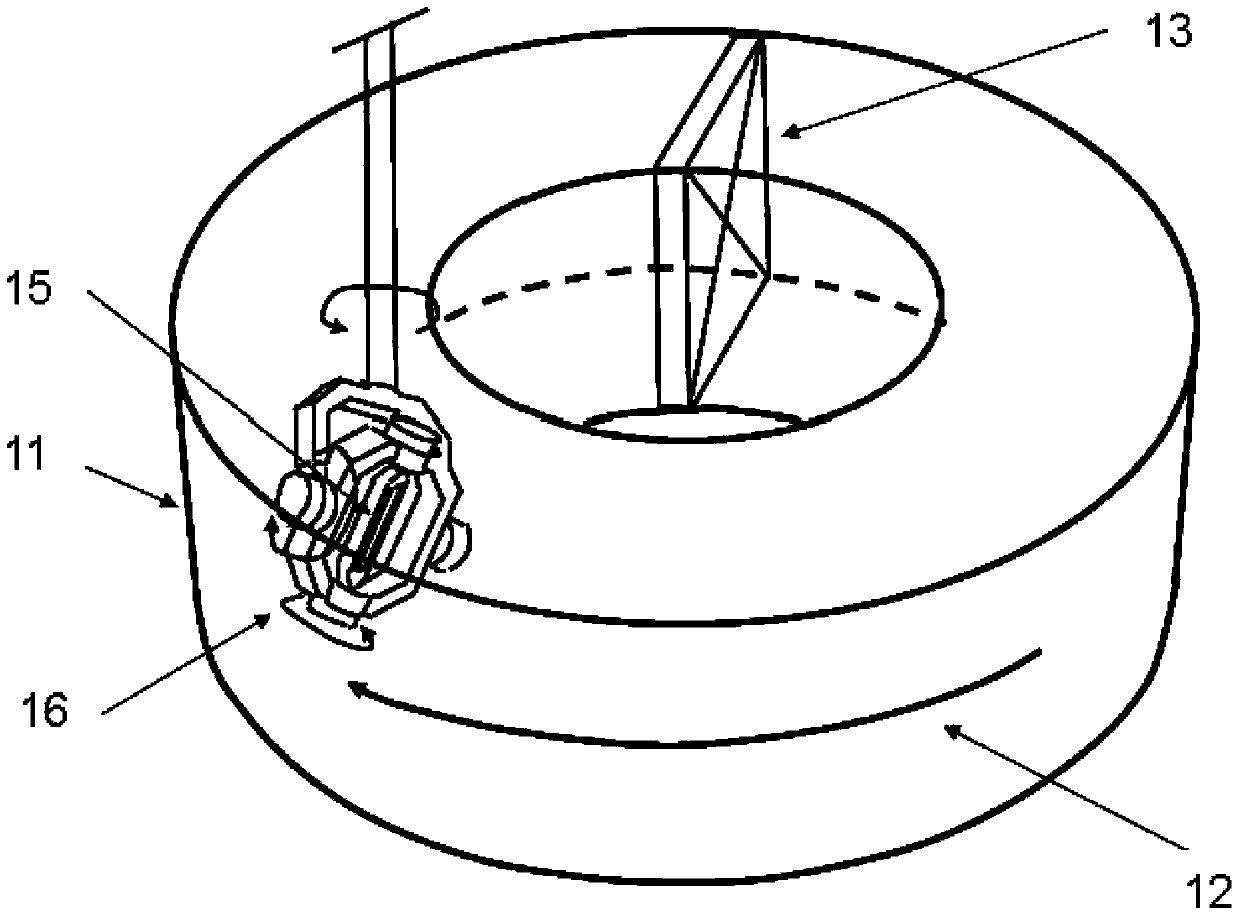

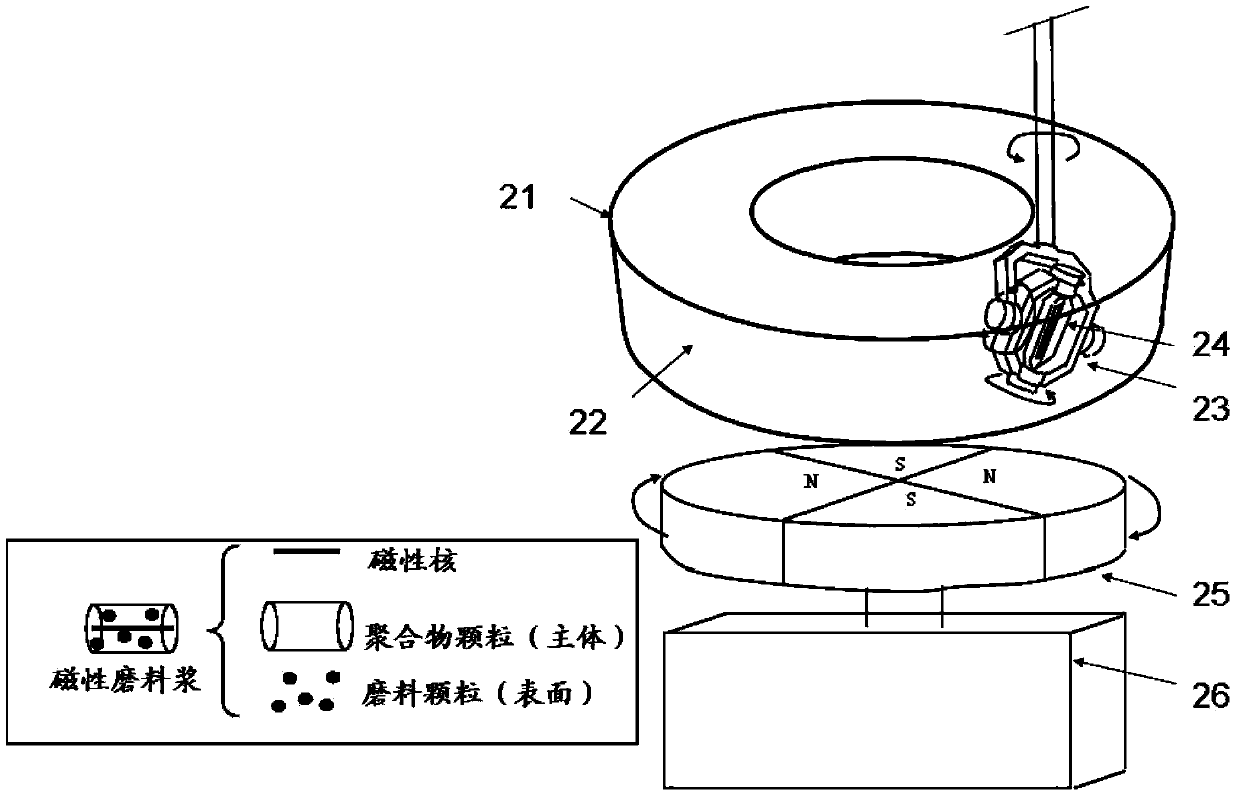

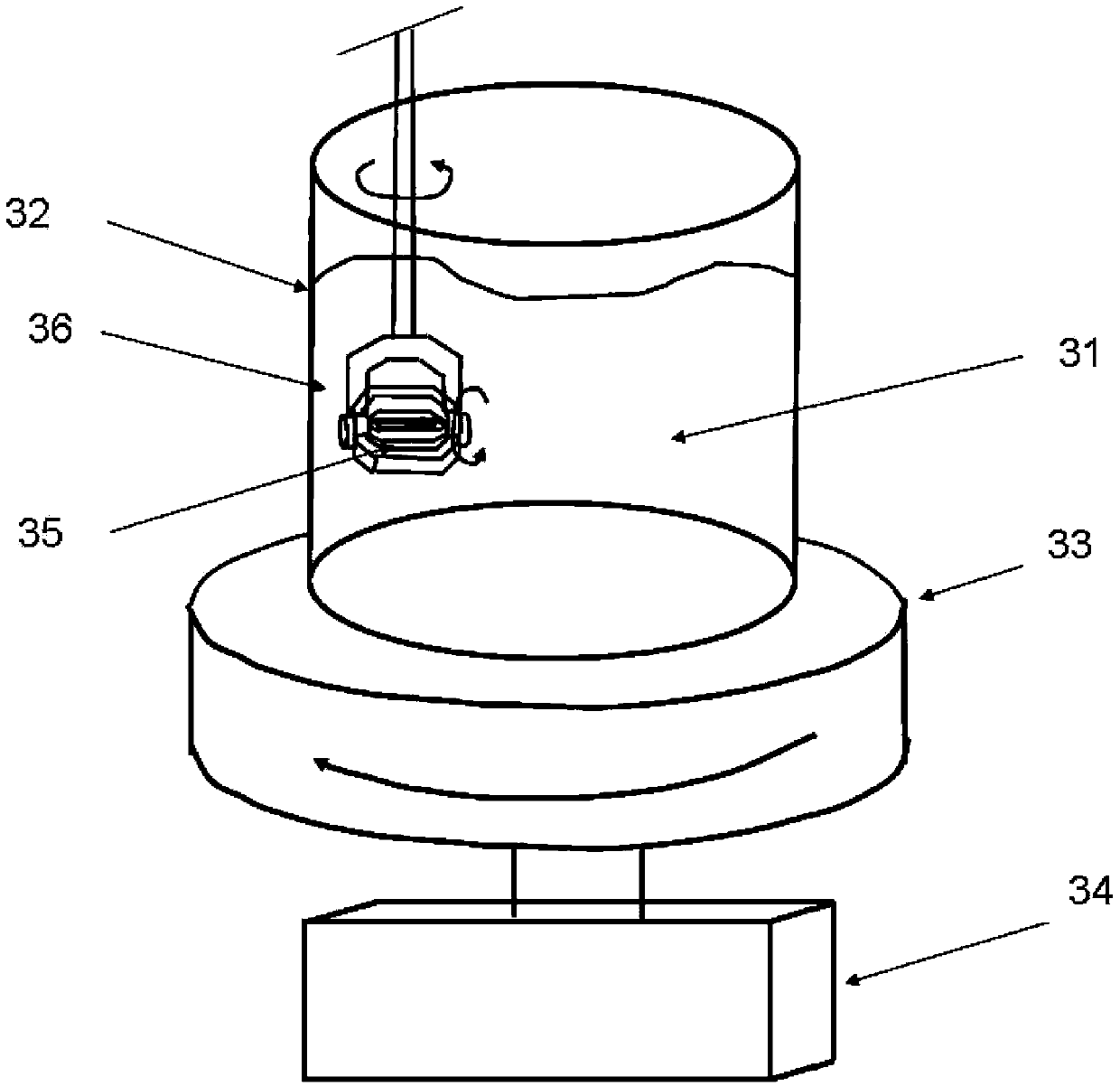

[0013] figure 1 An exemplary embodiment of the invention is shown. The automatic polishing apparatus in this embodiment comprises a circular container 11 containing an abrasive slurry 12 comprising a plurality of abrasive grains and a carrier liquid driven by a liquid pump 13, wherein the liquid pump 13 drives the abrasive slurry in the circular container. Abrasive slurry fluid 12 is formed in 11 . The workpiece 15 to be polished is mounted on a three-axis rotating platform 16 immersed in the abrasive slurry fluid 12 . By changing the orientation of the workpiece 15 in a controllable manner through the three-axis rotating platform 16, the three-axis rotating platform 16 can be automatically adjusted to achieve a gentle and uniform surface treatment of the workpiece 15. In one example, the workpiece 15 is an aluminum product with a complex curved surface profile, and its size is less than 50 (length) x 50 (width) x 50 (height) mm 3 . The workpiece 15 is dipped into an abras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com