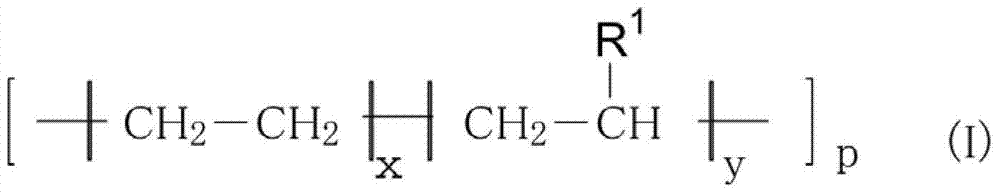

Antifouling coating composition and fishing net, fishing net appliance and underwater structure coated with the coating composition

A technology of antifouling coatings and compositions, applied in antifouling/underwater coatings, fishing nets, preservation of human or animal bodies, etc., capable of solving problems such as insufficient repelling effect of aquatic fouling organisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

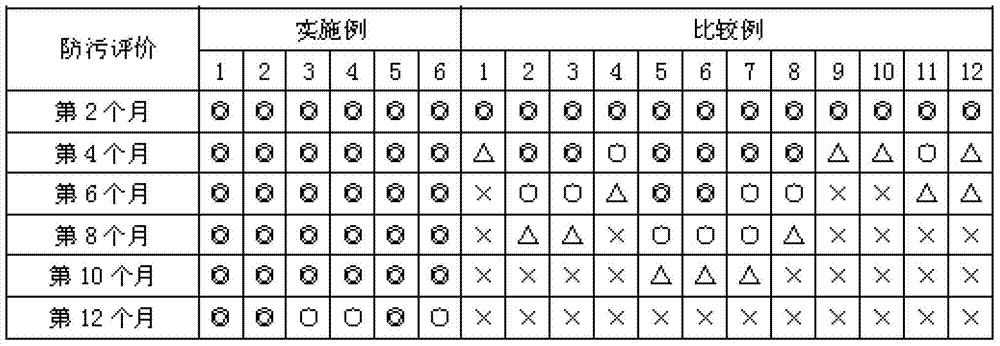

Examples

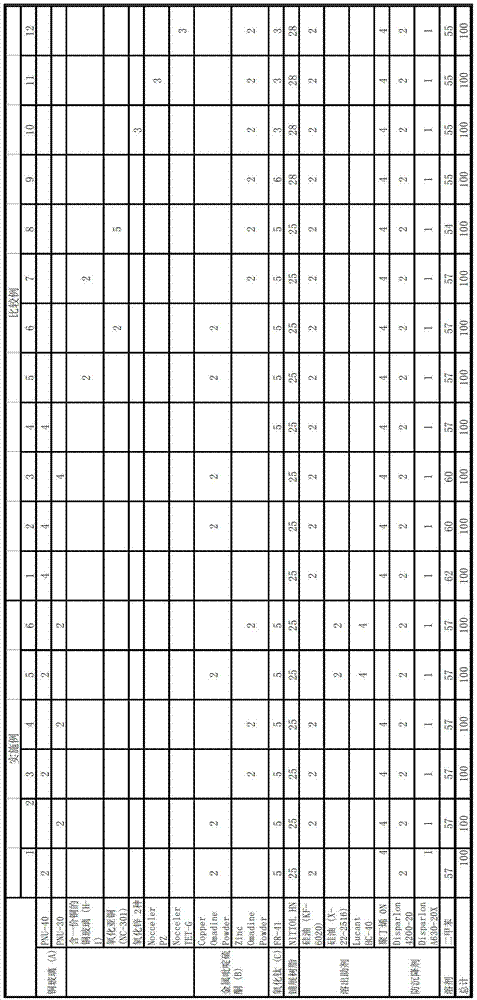

Embodiment 1~6 and comparative example 1~12

[0101] The compounding components described in Table 1 were mixed in the ratio (mass %) shown in Table 1, and the antifouling paint composition was obtained by this.

[0102] Trade name "PNU-40": copper glass containing divalent copper (P 2 o 5 / Na 2 O / CuO=30 / 30 / 40 (mol%), average particle size 3μ, manufactured by Toyo Glass Co., Ltd.)

[0103] Trade name "PNU-30": copper glass containing divalent copper (P 2 o 5 / Na 2 O / CuO=35 / 35 / 30 (mol%), average particle size 3μ, manufactured by Toyo Glass Co., Ltd.)

[0104] Product name "NC-301": cuprous oxide (manufactured by Nisshin Chemco Co., Ltd.)

[0105] Product name "Zinc Oxide 2 Types": Zinc Oxide (manufactured by Shodo Chemical Industry Co., Ltd.)

[0106] Product name "Nocceler PZ": zinc dimethyldithiocarbamate (manufactured by Ouchi Shinshin Chemical Co., Ltd.)

[0107] Product name "Nocceler TET-G": Tetraethylthiuram disulfide (manufactured by Ouchi Shinshin Chemical Industry Co., Ltd.)

[0108] Trade name "Copper O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com