Magnesium secondary battery anode material and application thereof

A technology for magnesium secondary batteries and negative electrode materials, which is applied in the field of electrochemical power sources, can solve problems such as lithium titanate materials not being successfully applied, and achieve the effects of being suitable for large-scale production, easy to obtain raw materials, and high degree of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

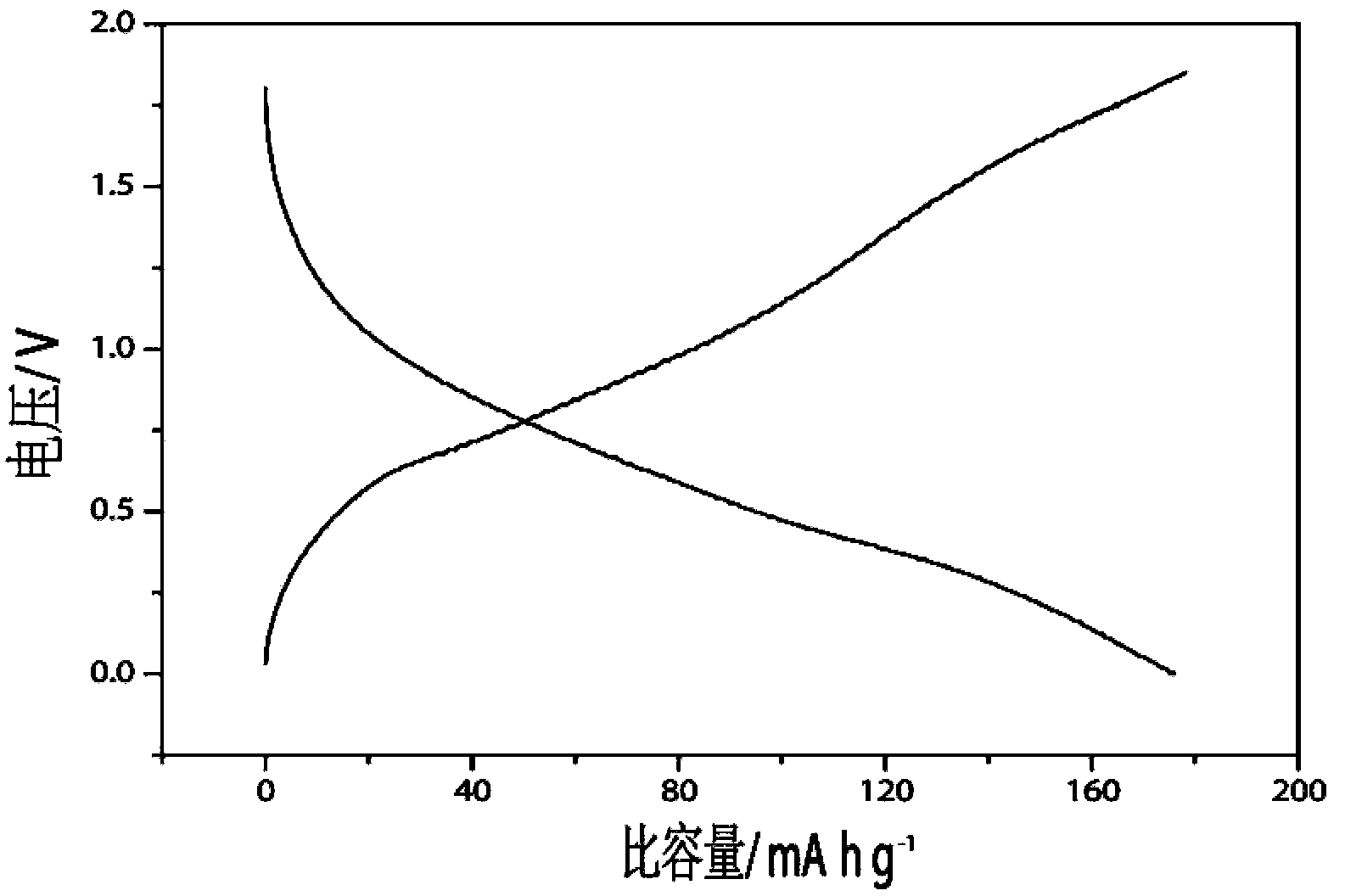

[0041] Press Li 2 CO 3 : The molar ratio of tetra-n-butyl titanate=4:5 is weighed, Li 2 CO 3 Soluble in ethanol / water to form a homogeneous solution. The uniformly mixed solution is placed in an oven to dry the solvent. The resulting solid was calcined at 600 °C for 10 h. After the reaction was completed, a powdery solid was obtained. The obtained lithium titanate has a particle size of 20nm, and after it is assembled with magnesium to form a battery, the discharge capacity of the battery reaches 175mA h / g. The battery exhibited good cycle stability.

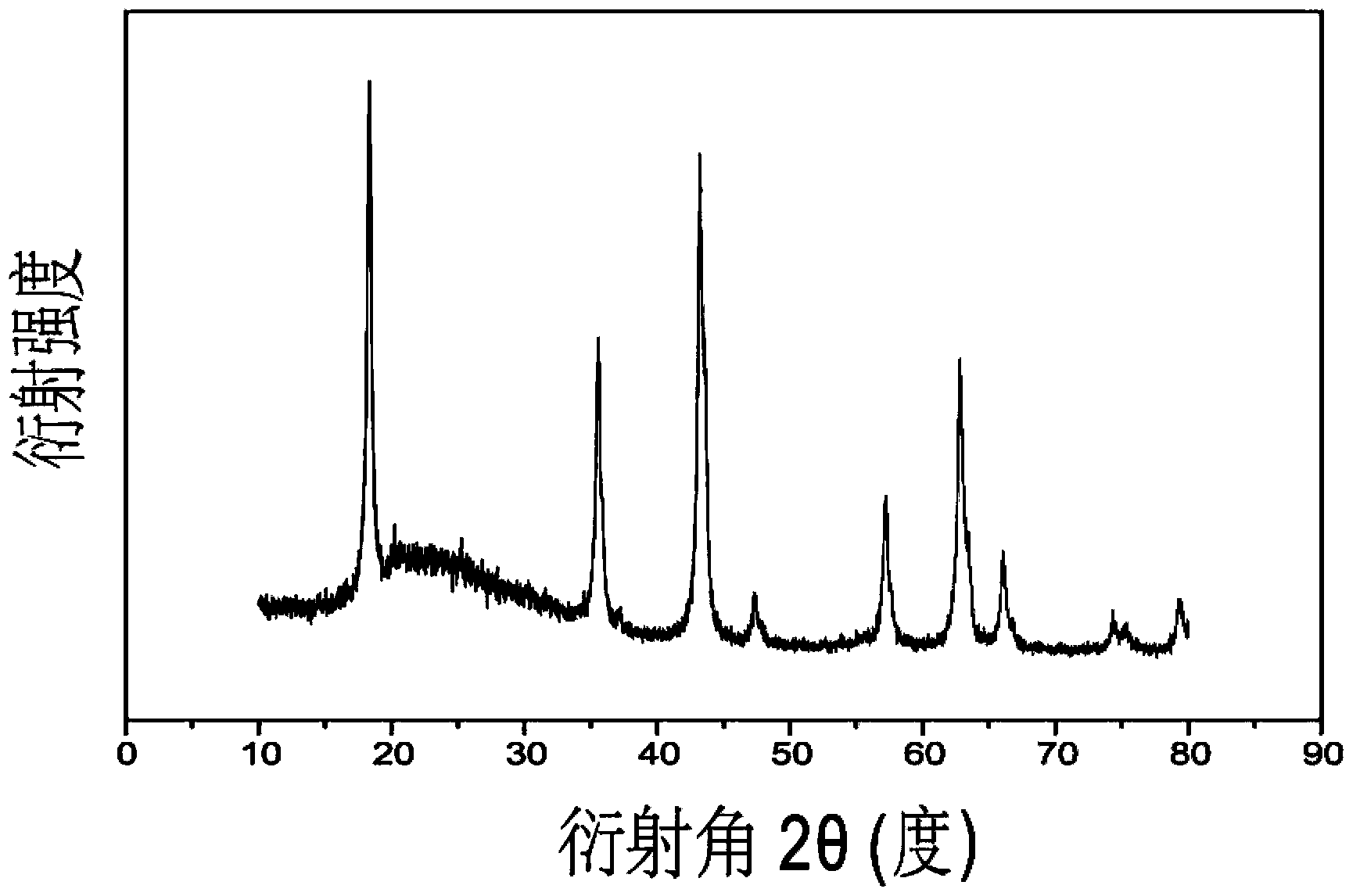

[0042] The structure was confirmed by powder X-ray diffractometer (Rigaku DmaxrB, CuKα ray). The result is as figure 1 shown. It can be seen from the figure that the impurity peak in the spectrogram is weaker, indicating that the product is relatively pure lithium titanate.

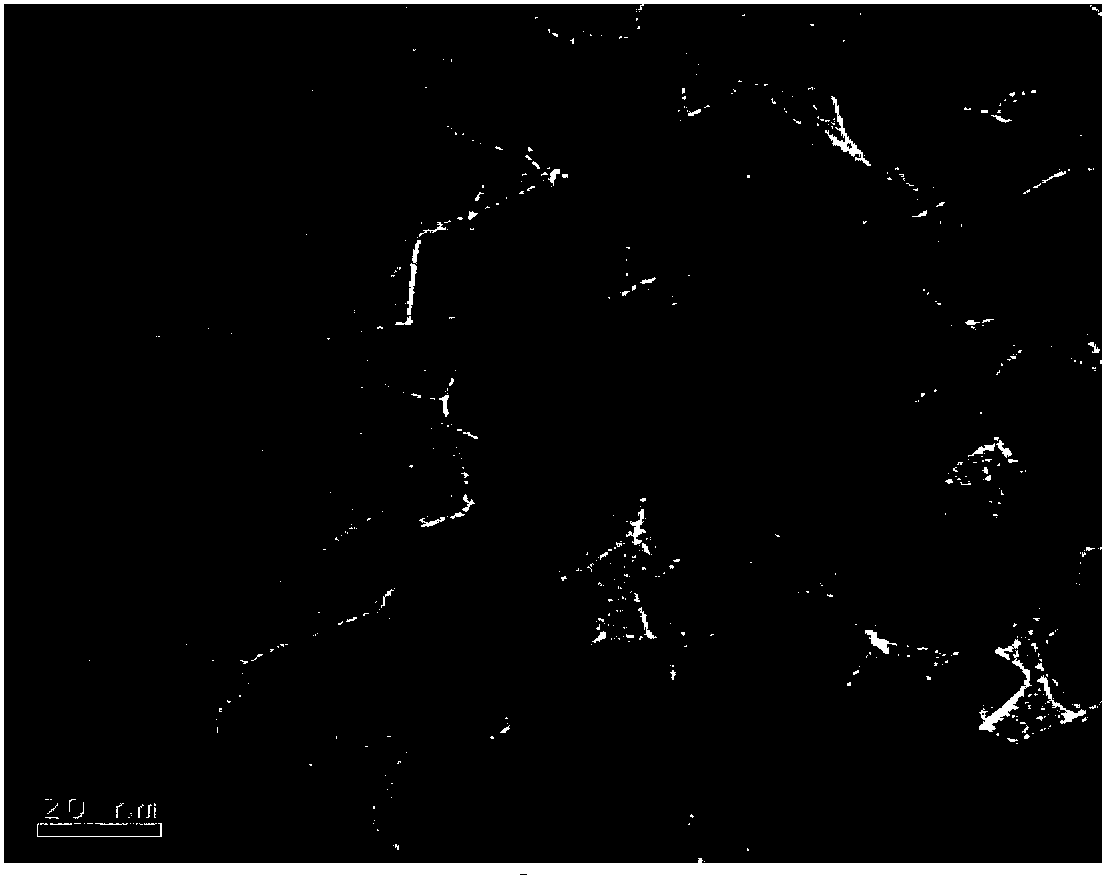

[0043] The particle size scale of the obtained samples was characterized by a transmission electron microscope (TEM, Tecnai F30, working voltage ...

comparative example 1-1

[0049] Other conditions are the same as in Example 1, except that different titanium sources (TiSO 4 ) and the resulting lithium titanate has a particle size of 80nm, and after it is assembled with magnesium into a battery, the battery has no activity.

comparative example 1-2

[0051] The battery preparation process is the same as in Example 1, except that commercial lithium titanate (Adrich Company) is selected. The particle size of this lithium titanate is 1 μm. After it is assembled with magnesium to form a battery, the battery has no activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com