Thin-film LED (Light-Emitting Diode) device and manufacturing method thereof

An LED device and thin-film technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of complex and precise special equipment for plastic packaging process, broken gold wires on light-guiding panels of devices, high cost of improvement and upgrading, and achieve industrialization. The chemical prospect is considerable, the light-emitting angle is large, and the effect of reducing the use of plastic molding molds and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

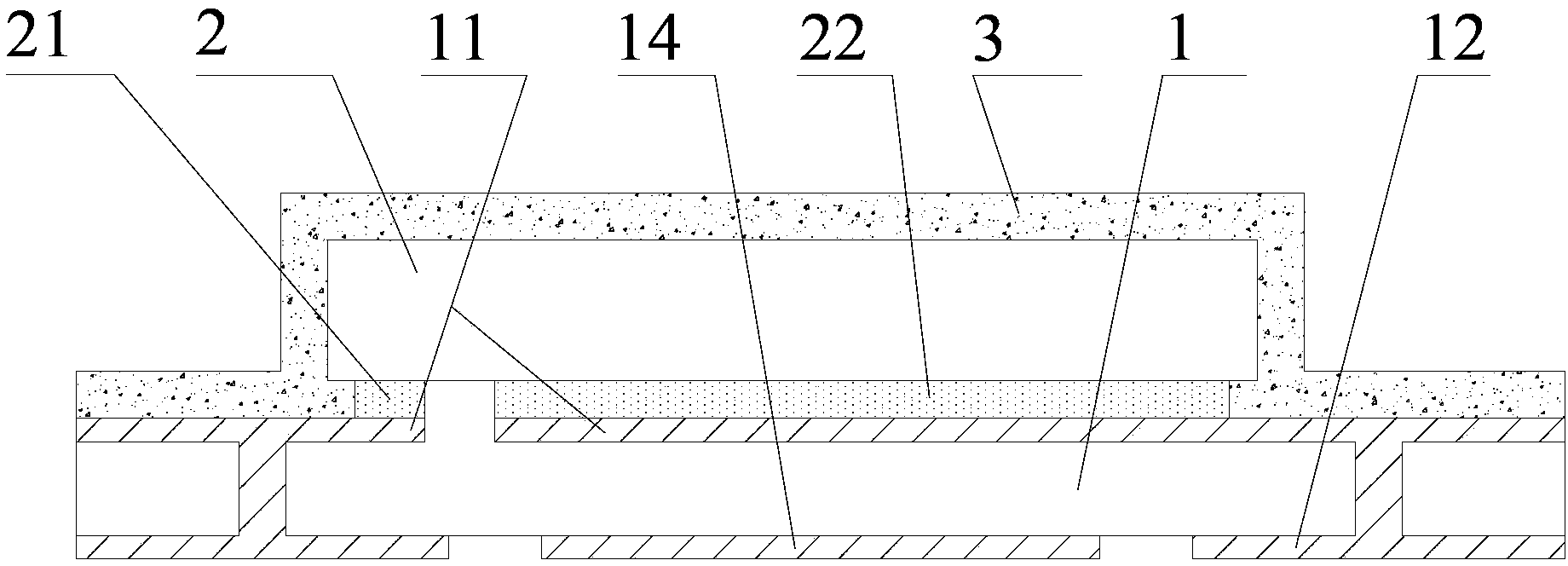

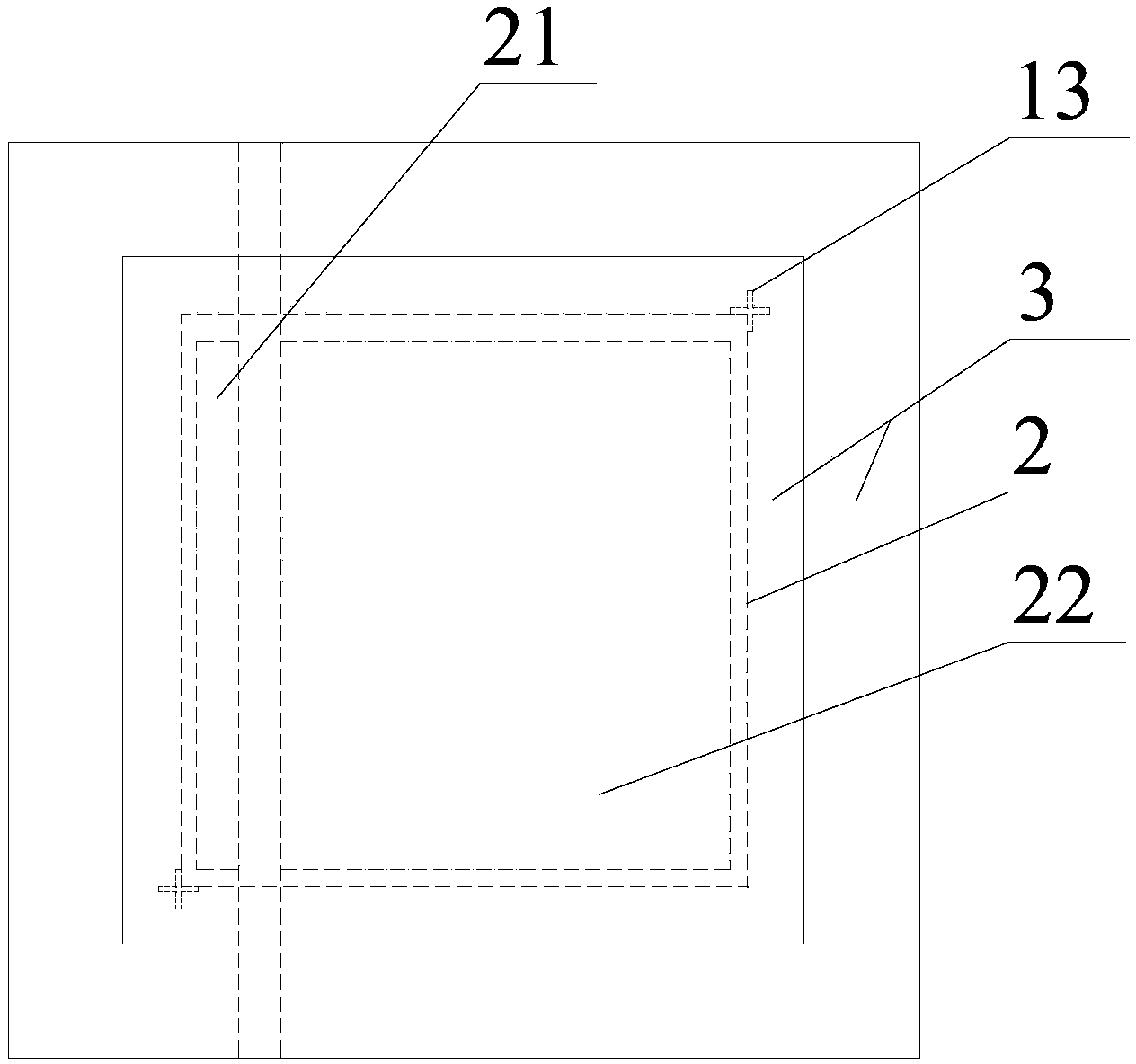

[0036] This embodiment provides a thin-film LED device, which is now combined figure 1 versus figure 2 This invention is specifically described.

[0037] figure 1 Is a structural cross-sectional view of a thin-film LED device according to the present invention, as shown in the figure,

[0038] A thin-film LED device includes a thin-film circuit support 1, an LED chip 2 with a gold wire-free flip-chip structure, and a light-transmitting protective film 3. The LED chip 2 has a thickness of 0.1 mm, and the positive and negative electrodes of the LED chip 2 It is bonded to the upper surface circuit layer 11 of the sheet-type circuit support 1 by eutectic welding, and the lower surface circuit layer 12 of the sheet-type circuit support 1 is connected to the upper surface circuit layer through the circuit and is respectively connected to the positive and negative circuits of the LED chip 2 In connection, the light-transmitting protective film 3 tightly covers the top and surroundings of...

Embodiment 2

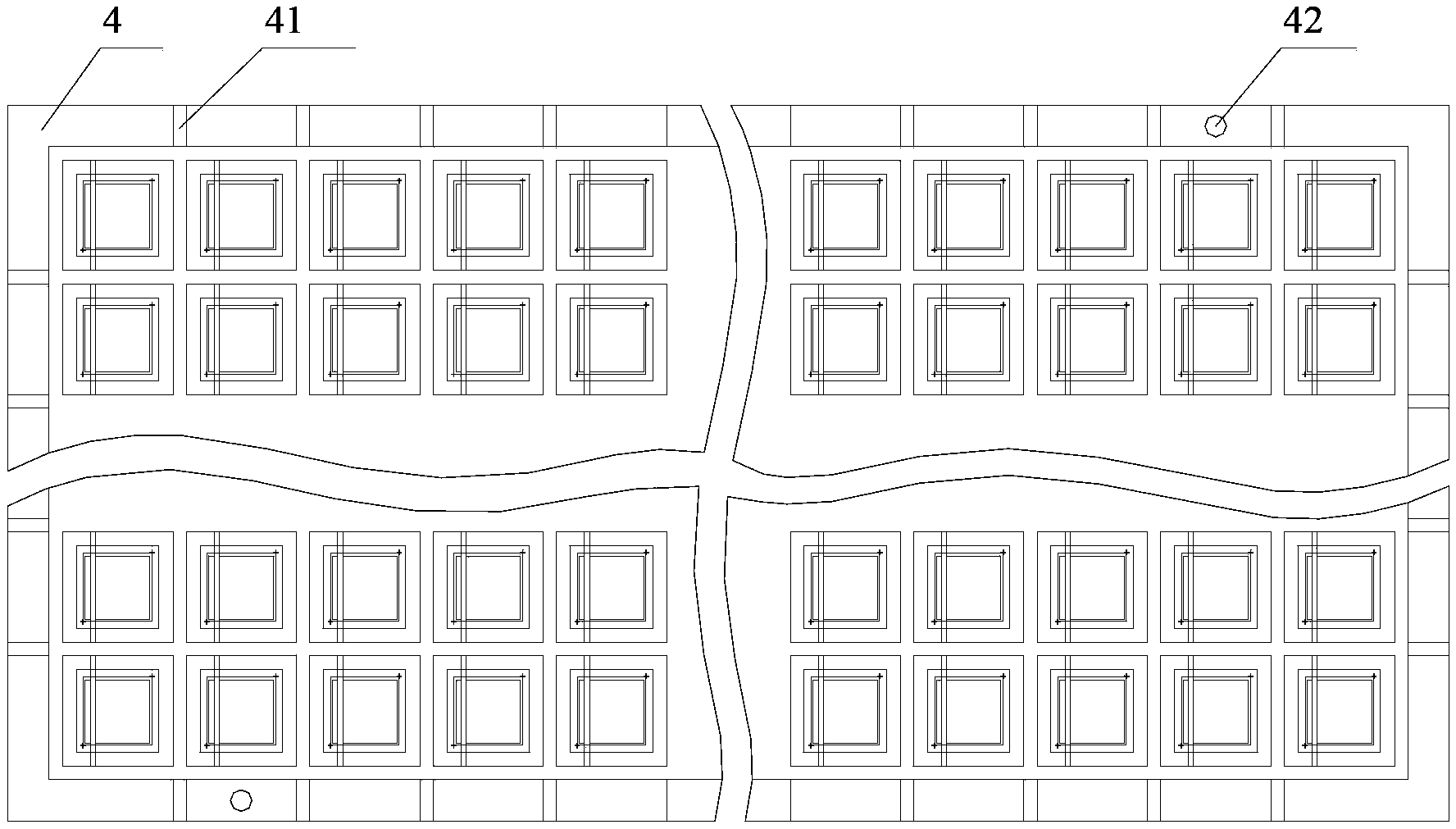

[0047] This embodiment proposes a method of manufacturing a thin-film LED device, which is now combined image 3 , Figure 4 versus Figure 5 This is a further description and explanation of the manufacturing method proposed by the present invention.

[0048] A method of manufacturing a thin-film LED device includes the steps:

[0049] S1. Flux is placed on the center point of each bracket unit of the sheet-type circuit substrate 4 with positioning holes 42 at the edge, the area of the flux is equivalent to the area of the bottom electrode of the LED chip 2, and the flux is a rosin-like glue;

[0050] S2. Place the LED chip 2 on the sheet-type circuit substrate 4 on which the flux has been spotted. When the LED chip 2 is placed, the LED chip 2 is positioned according to the LED chip placement mark 13;

[0051] S3. Put the sheet-type circuit substrate 4 on which the LED chip 2 is placed into a reflow furnace for eutectic solidification;

[0052] S4. Spray a layer of liquid adhesive 5...

Embodiment 3

[0061] This embodiment proposes a method of manufacturing a thin-film LED device, which is now combined image 3 Figure 4 versus Figure 5 This is a further description and explanation of the manufacturing method proposed by the present invention.

[0062] A method of manufacturing a thin-film LED device includes the steps:

[0063] S1. Flux is placed on the center point of each bracket unit of the sheet-type circuit substrate 4 with positioning holes 42 at the edge, the area of the flux is equivalent to the area of the bottom electrode of the LED chip 2, and the flux is a rosin-like glue;

[0064] S2. Place the LED chip 2 on the sheet-type circuit substrate 4 on which the flux has been spotted. When the LED chip 2 is placed, the LED chip 2 is positioned according to the LED chip placement mark 13;

[0065] S3. Put the sheet-type circuit substrate 4 on which the LED chip 2 is placed into a reflow furnace for eutectic solidification;

[0066] S4. Spray a layer of liquid adhesive 5 u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com