Gallium nitride substrate and epitaxial wafer

一种氮化镓基板、物理性的技术,应用在半导体器件、电气元件、半导体/固态器件制造等方向,能够解决不良、发光强度降低、成品率降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

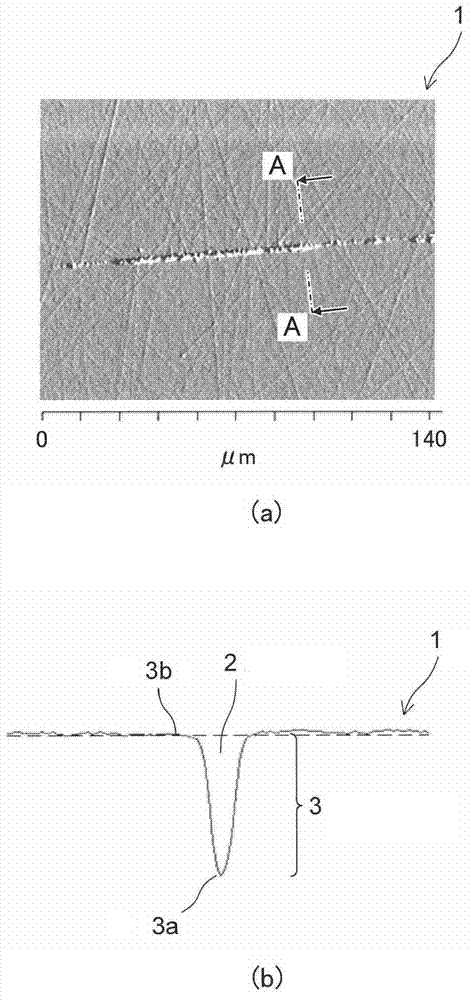

[0037] The inventors of the present invention conducted in-depth investigations and found that even if there is a physical level difference caused by scratches on the surface of the gallium nitride substrate, it is not necessarily impossible to achieve good epitaxial crystal growth. The size of the physical height difference is relatively small, and the difference in the intensity of cathodoluminescence at the wavelength corresponding to the band gap of the gallium nitride substrate at the upper and lower parts of the physical height difference is small, and the abnormality of the crystal on the substrate can be suppressed Growth can grow crystals with flat surfaces.

[0038] The intensity of cathodoluminescence varies depending on the state of the crystals at the measurement site, and if the difference in the intensity of cathodoluminescence between the upper and lower parts of the physical level difference is large, it means that the crystal states of the upper and lower part...

Embodiment 1

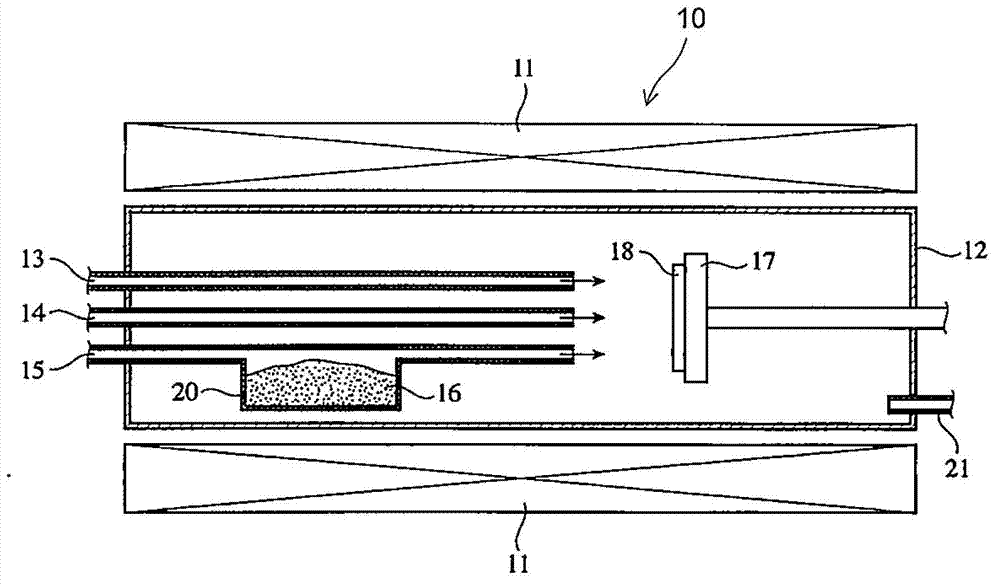

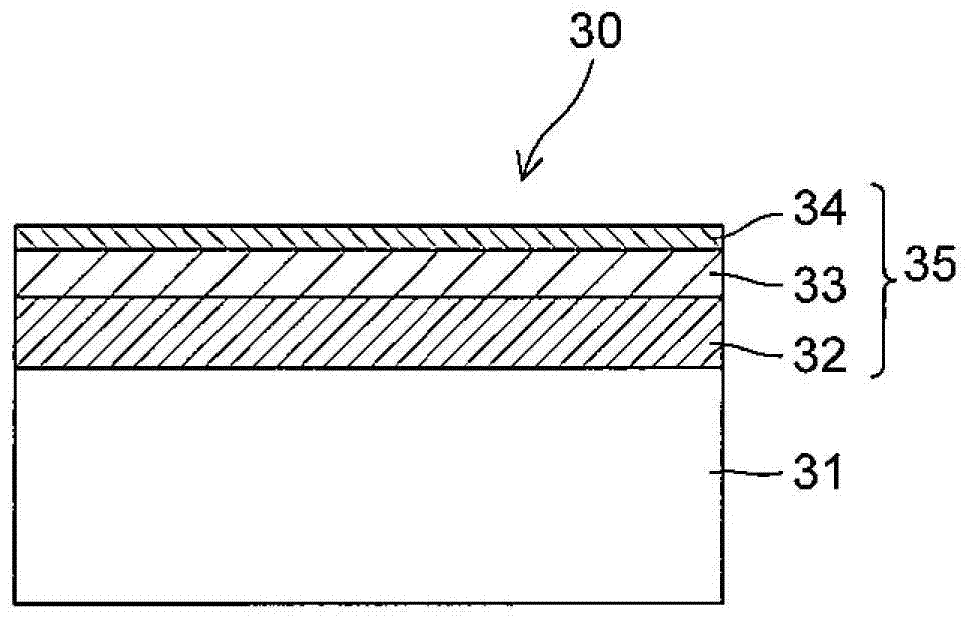

[0063] In Example 1, 25 gallium nitride substrates were formed by the VAS method. Next, the physical height difference was measured for each substrate using a three-dimensional optical profiler, and 20 evaluation regions were determined for the size of the physical height difference. Next, cathodoluminescence measurement was performed on each evaluation region of each substrate. Next, an epitaxial growth layer was grown on each gallium nitride substrate to form a quantum well structure, and an epitaxial wafer was obtained. Next, photoluminescence measurement was performed on each epitaxial wafer, and the average measurement value in each evaluation area was obtained to evaluate the surface flatness, and the relationship between the size of the physical height difference and the result of cathodoluminescence measurement was investigated. The specific steps are described below.

[0064] (Manufacturing of gallium nitride substrates)

[0065] First, a GaN base layer with a thic...

Embodiment 2

[0111] In Example 2, the implementation conditions of the mechanical polishing of the Ga polar surface in the manufacturing steps of the gallium nitride substrates (1) to (25) in Example 1 were respectively changed to pressure: 0.45 MPa and polishing implementation time: In 25 minutes, gallium nitride substrates ( 26 ) to ( 50 ) were produced. Other manufacturing conditions are the same as those of gallium nitride substrates (1) to (25).

[0112] (Measurement of physical height difference)

[0113] By the same method as in Example 1, the physical height differences caused by scratches and the like on the surfaces of the gallium nitride substrates (26) to (50) were measured, and 10 evaluation regions d1 were determined for the size of the physical height differences. ~d10.

[0114] In the gallium nitride substrates ( 26 ) to ( 50 ), no physical difference in height exceeding 2 μm was observed. This is considered to be because the surface of the substrate was further flattene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com