Vehicle solid-state relay

A solid-state relay, vehicle technology, applied in relay ventilation/cooling/heating and other directions, can solve the problems of low reliability, poor heat dissipation, poor sealing performance, etc., to improve heat dissipation, long service life, and improved sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

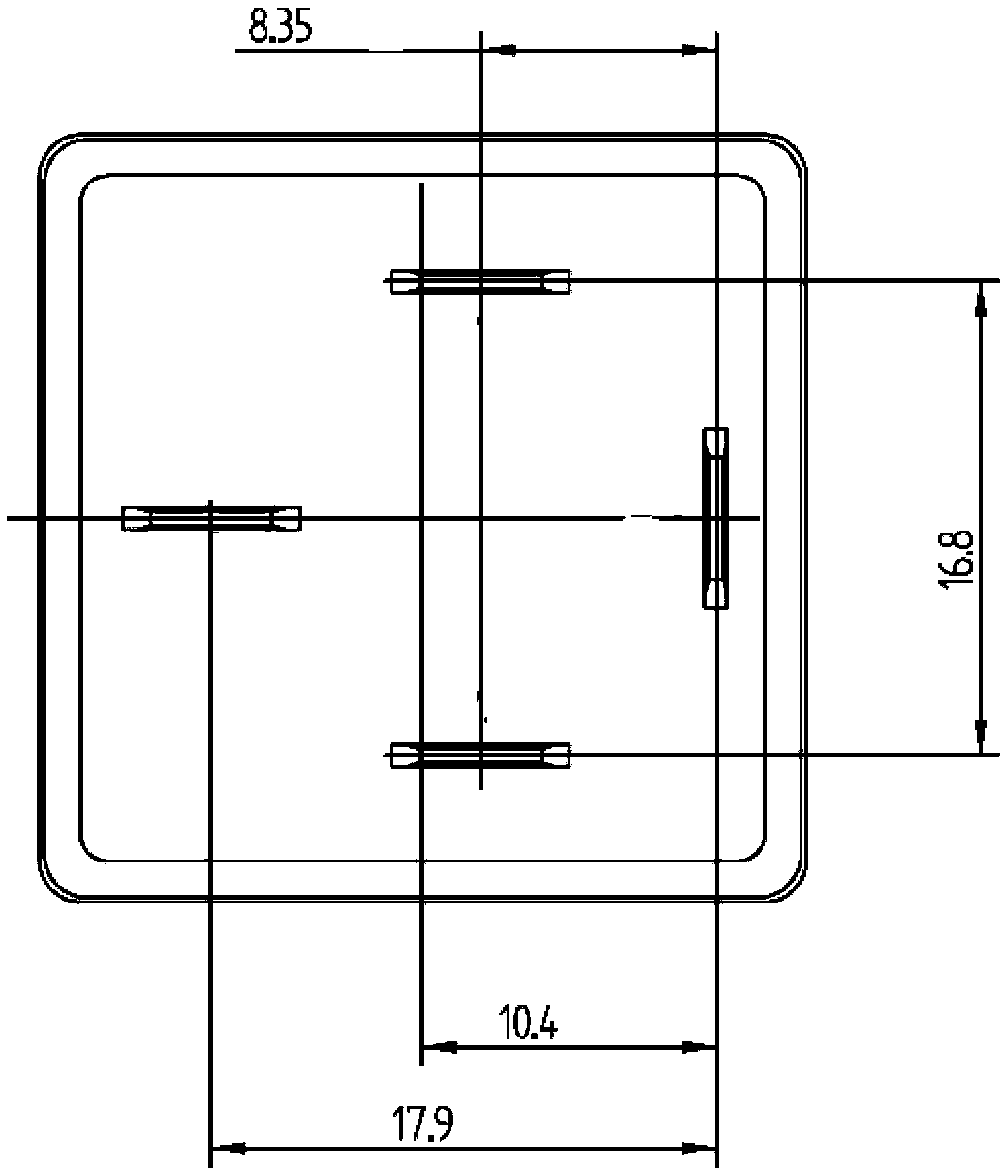

[0032] see image 3 , 4 , a solid-state relay for vehicles. Its pin arrangement and size conform to the ISO Mini relay standard. At present, German, American, and some self-owned brand models use this pin specification relay.

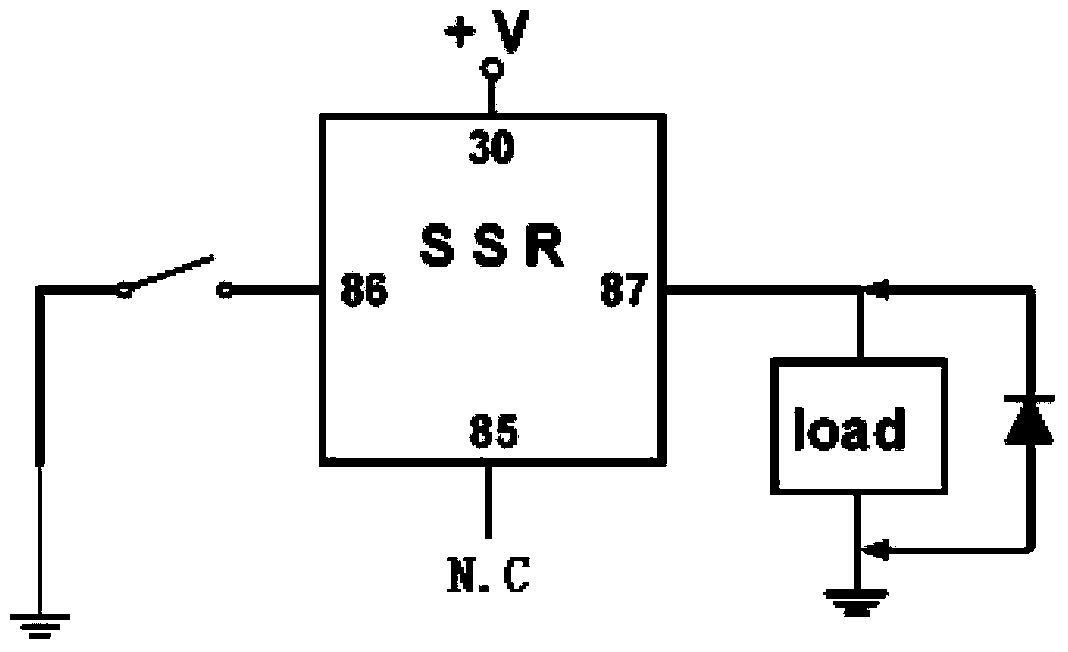

[0033] Its peripheral wiring diagram is as follows figure 1 shown, where:

[0034] Terminal 30: connected to the battery power supply;

[0035] Terminal 86: connected to the low-side switch, used to control the on-off of the solid-state relay;

[0036] Terminal 87: connected to the load, if it is a high-power inductive load (fan, motor, electromagnetic coil, etc.), the reverse electromotive force suppression diode should be connected in parallel at both ends of the load.

[0037] Terminal 86: Empty pin.

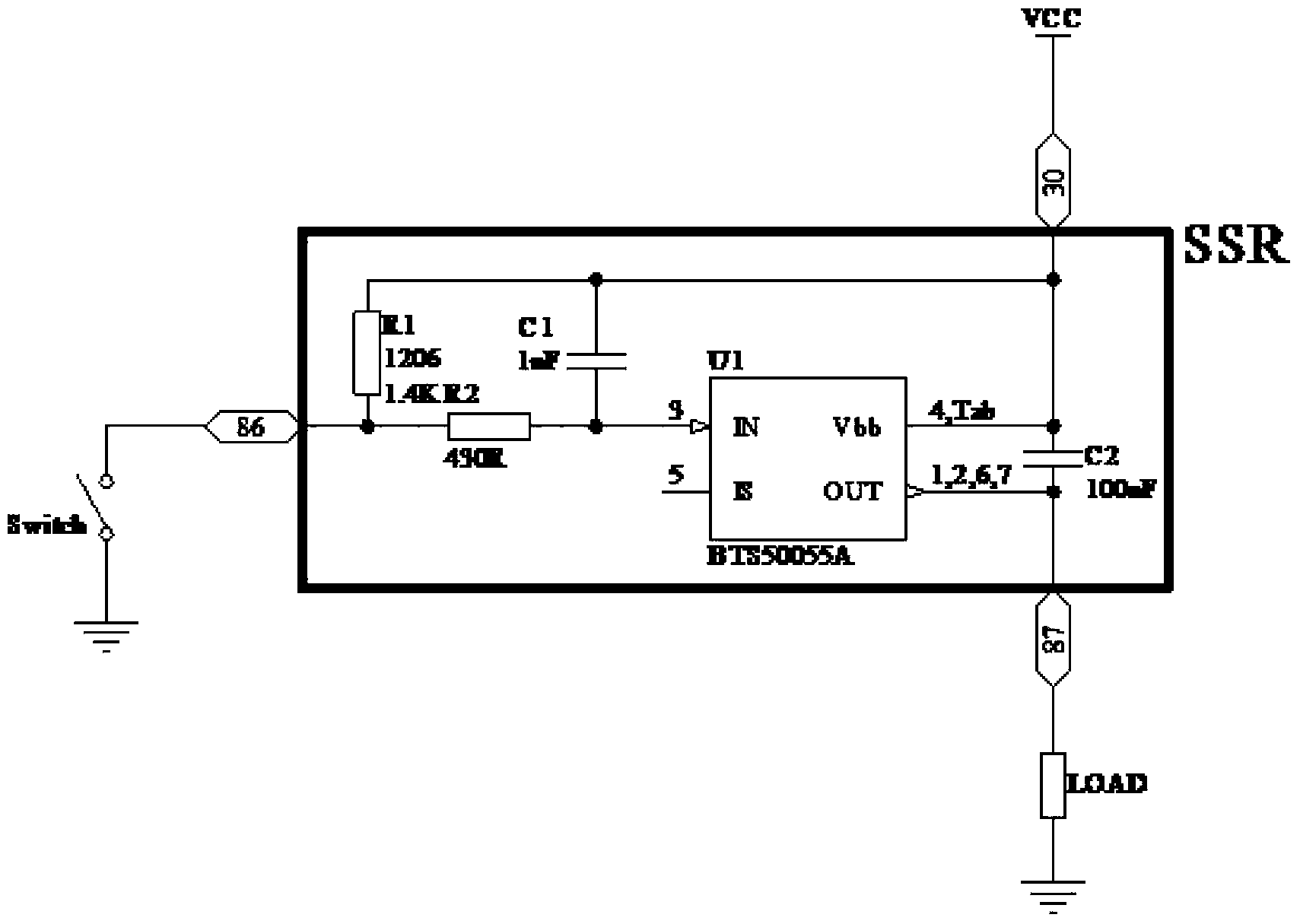

[0038] The internal circuit of the solid state relay is as figure 2 As shown, when the 86-pin is grounded through the switch, the current of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com