Cable for hydraulic observation

A cable and hydraulic technology, which is applied in the field of hydraulic observation equipment, can solve the problems of increased procurement costs, no involvement in vertical waterproof technology, waste of materials, etc., and achieve the effect of enhancing the water blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be specifically described below in conjunction with the accompanying drawings.

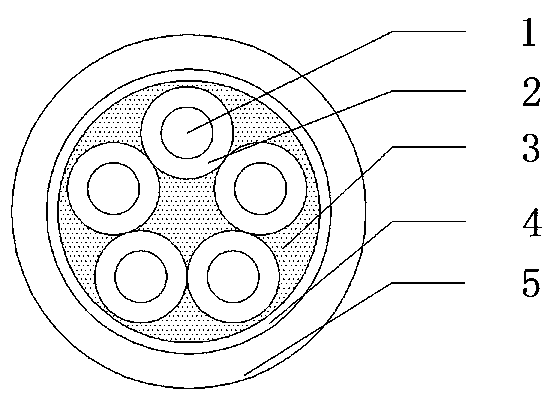

[0025] In this embodiment, the five-core hydraulic observation cable is taken as an example, such as figure 1 As shown, the hydraulic observation cable is composed of five wire cores twisted from the inside to the outside, wrapped around the cladding 4 and the outer sheath 5 .

[0026] Each of the five wire cores is composed of a conductor 1 and a layer of low-density polyethylene insulating layer 2 extruded therefrom. Conductor 1 is made of 27 tinned copper wires with a diameter of 0.20 mm twisted according to a pitch-to-diameter ratio of 8. Five wire cores are twisted into cables according to the ratio of pitch to diameter of 10~12. Tinned copper wire.

[0027] When the cores are twisted into a cable, the cores are densely filled and evenly coated with petroleum jelly with a thickness of 0.5~0.8mm as filler 3. A layer of water-blocking tape is overlapped and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com