Three-point support optimization design method of machine tool bed based on response surface model

A response surface model, three-point support technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as time-consuming, low optimization efficiency and optimization accuracy, and optimal combination of difficult parameters, reducing machine tools. Deformation, improving efficiency and optimizing accuracy, the effect of improving the machining accuracy of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

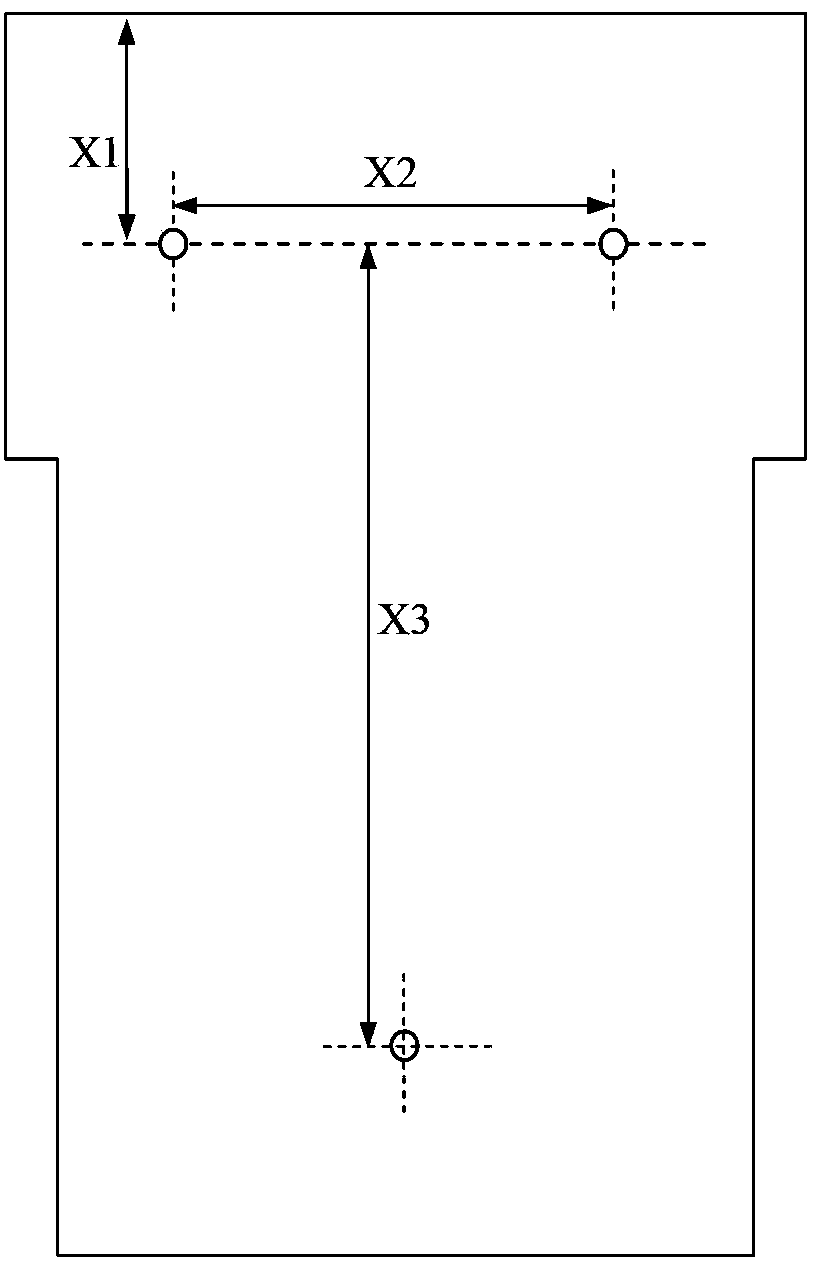

[0034] A three-point support optimization method for a machine tool bed based on a response surface model of the present invention will be described in detail below in combination with embodiments and drawings.

[0035] The present invention aims at problems such as difficult leveling of existing machine tools, low optimization efficiency of large machine tool structures, and difficulty in ensuring the global optimality of optimization results, etc., and proposes a three-point support optimization design method for machine tool bed based on response surface model, which efficiently realizes The optimized design of the three-point support of the bed structure achieves the purpose of improving the optimization efficiency and precision, and finally achieves the purpose of easy leveling of the machine tool and improvement of the machining accuracy of the machine tool.

[0036] A kind of three-point support optimization design method of machine tool bed based on response surface mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com