High-bearing-capacity sand filling pipe pile with pile joints and manufacturing and construction method of pile

A technology of bearing capacity and sand filling pipes, applied in the field of building foundations, can solve problems such as user inconvenience, lower bearing capacity, increased silt stress and water pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

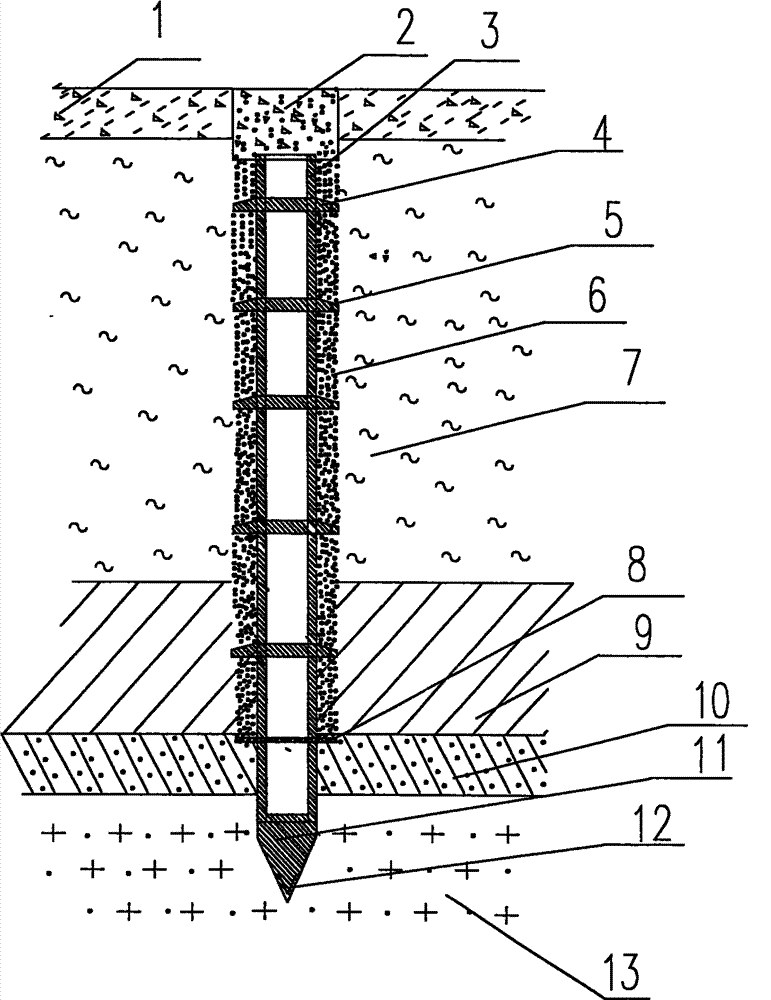

[0017] figure 1 Shown is a typical embodiment of the present invention, a high-bearing-capacity sand-filled pipe pile with pile joints includes a tubular pile body (3) of prestressed reinforced concrete, which is characterized in that, on the pipe pile body (3), each There are pile joints (4) which are 10cm larger than the pile body (3) every 2m, and the pile joints (4) are 10cm wide. Vertical drainage holes (5) are arranged on the pile joints (4), and outside the pile body (3) there are 10cm thick fill sand (6).

[0018] The following brief description embodiment makes construction method:

[0019] ①. Binding prestressed steel bars in the lower mold of the pipe pile with pile joints;

[0020] ②. Pre-embed a small plastic pipe for drainage on the pile joint of the lower mold, then pour concrete into the lower mold, cover the upper mold, and tighten the interlocking bolts of the upper and lower molds;

[0021] ③. The upper and lower molds rotate at high speed to make the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com