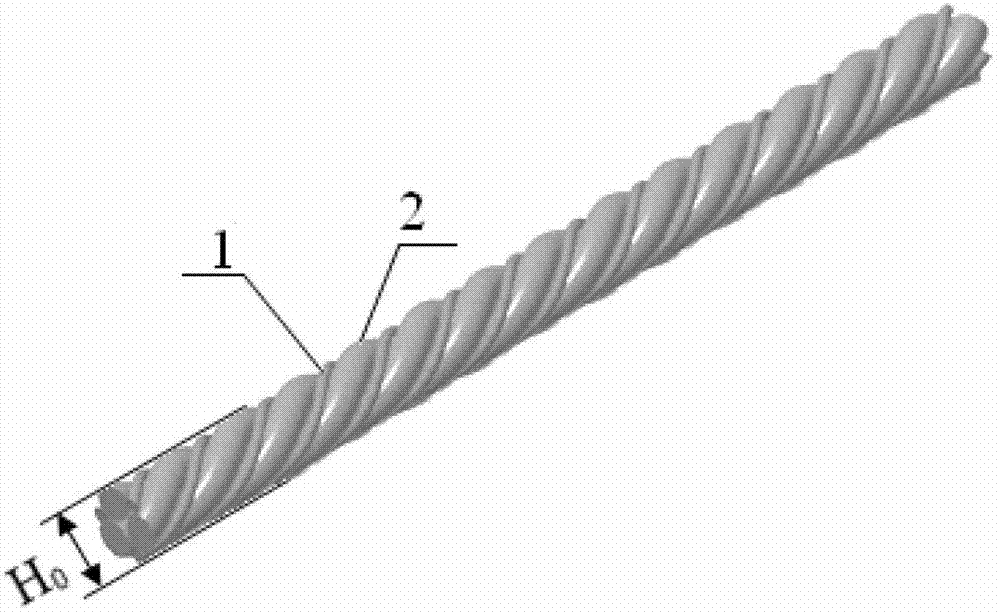

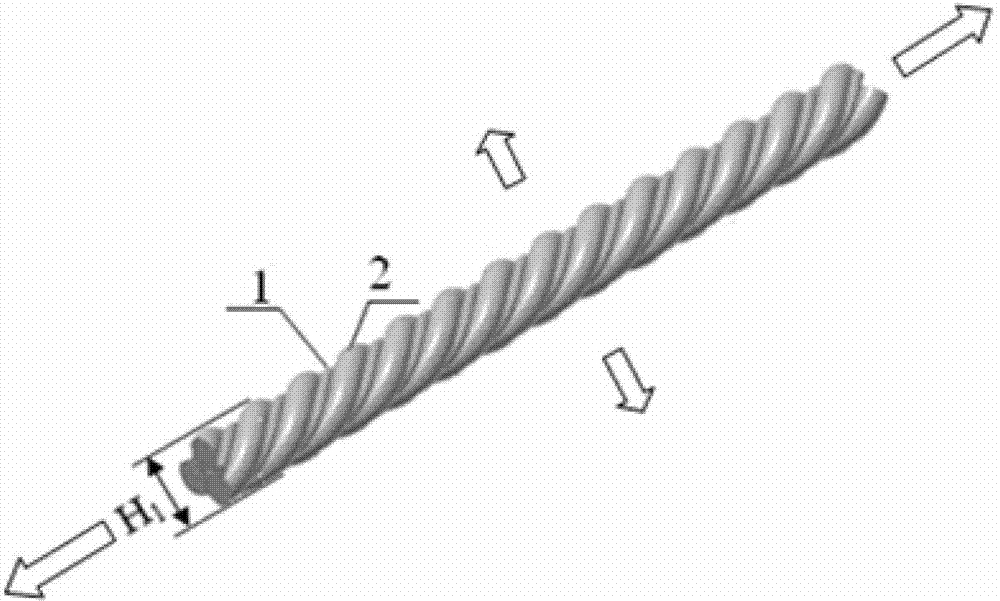

Negative poisson ratio yarn structure and manufacturing method thereof

A technology of negative Poisson's ratio and manufacturing method, which is applied in the directions of yarn, textiles and papermaking, can solve the problems of unstable twist of yarn structure, small effect of negative Poisson's ratio, uneven yarn surface, etc., and is easy to popularize and implement. , Simple operation, wide selection of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

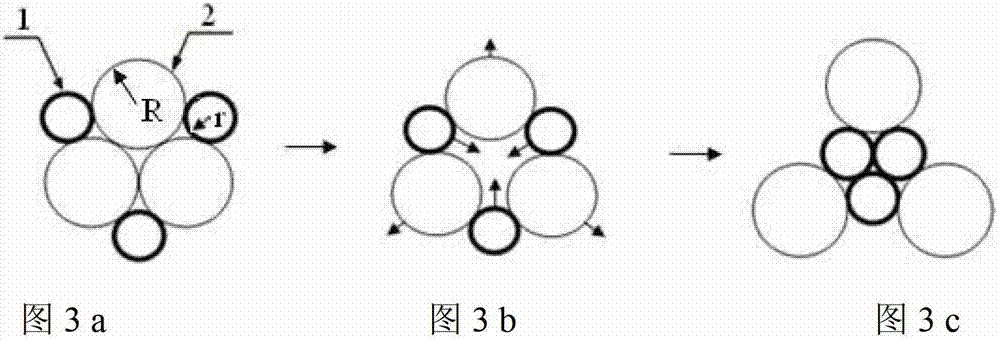

Embodiment 1

[0048] Elastic yarns with a smaller tensile modulus and nylon filaments with a larger tensile modulus were selected as the second yarn and the first yarn respectively, wherein the diameter of the elastic yarn was 0.5mm, and the diameter of the nylon filament was 0.4mm. The two elastic yarns and nylon filaments are simultaneously fed from the bobbin 3 to the yarn forming area through the yarn tension device. Arranged alternately; by rotating the slotted turntable 4, the rubber band yarn and the nylon filament fed are twisted simultaneously, and it is then converged into a negative Poisson's ratio yarn structure at the entrance of the twisting and gathering device 5; through the roller device 6 and adding The twist accumulating device 5 pulls the twisted and formed negative Poisson's ratio yarn structure out of the yarn forming area and winds it onto the winding device 7 . In this embodiment, the twist of the final negative Poisson's ratio yarn structure is adjusted by adjusting...

Embodiment 2

[0051] An elastic thread with a small tensile modulus and a fishing line with a large tensile modulus are respectively selected as the second yarn and the first yarn, wherein the diameter of the elastic thread is 0.7mm, and the diameter of the fishing line is 0.5mm. The three elastic threads and fishing lines are simultaneously fed from the bobbin 3 to the yarn forming area through the yarn tension device. Arranged alternately; by rotating the slotted turntable 4, the fed elastic thread and fishing line are simultaneously twisted, which is then converged into a negative Poisson's ratio yarn structure at the entrance of the twisting and gathering device 5; through the roller device 6 and adding The twist accumulating device 5 pulls the twisted and formed negative Poisson's ratio yarn structure out of the yarn forming area and winds it onto the winding device 7 . In this embodiment, the twist of the final negative Poisson's ratio yarn structure is adjusted by adjusting the rotat...

Embodiment 3

[0054] Select glass fiber with less tensile modulus and carbon fiber with larger tensile modulus as the second yarn and the first yarn respectively, wherein the diameter of glass fiber is 0.2mm, and the diameter of carbon fiber is 0.1mm; The steps are the same as in Example 1, and will not be repeated here. The number of twists of the negative Poisson's ratio yarn prepared in Example 3 is 50 twists / meter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com