Extraction method of plant essential oil

A plant essential oil and extraction technology, applied in the directions of essential oils/spices, fat production, etc., can solve the problems of small content, low extraction rate, high price, etc., and achieve the effect of improving the yield of essential oils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

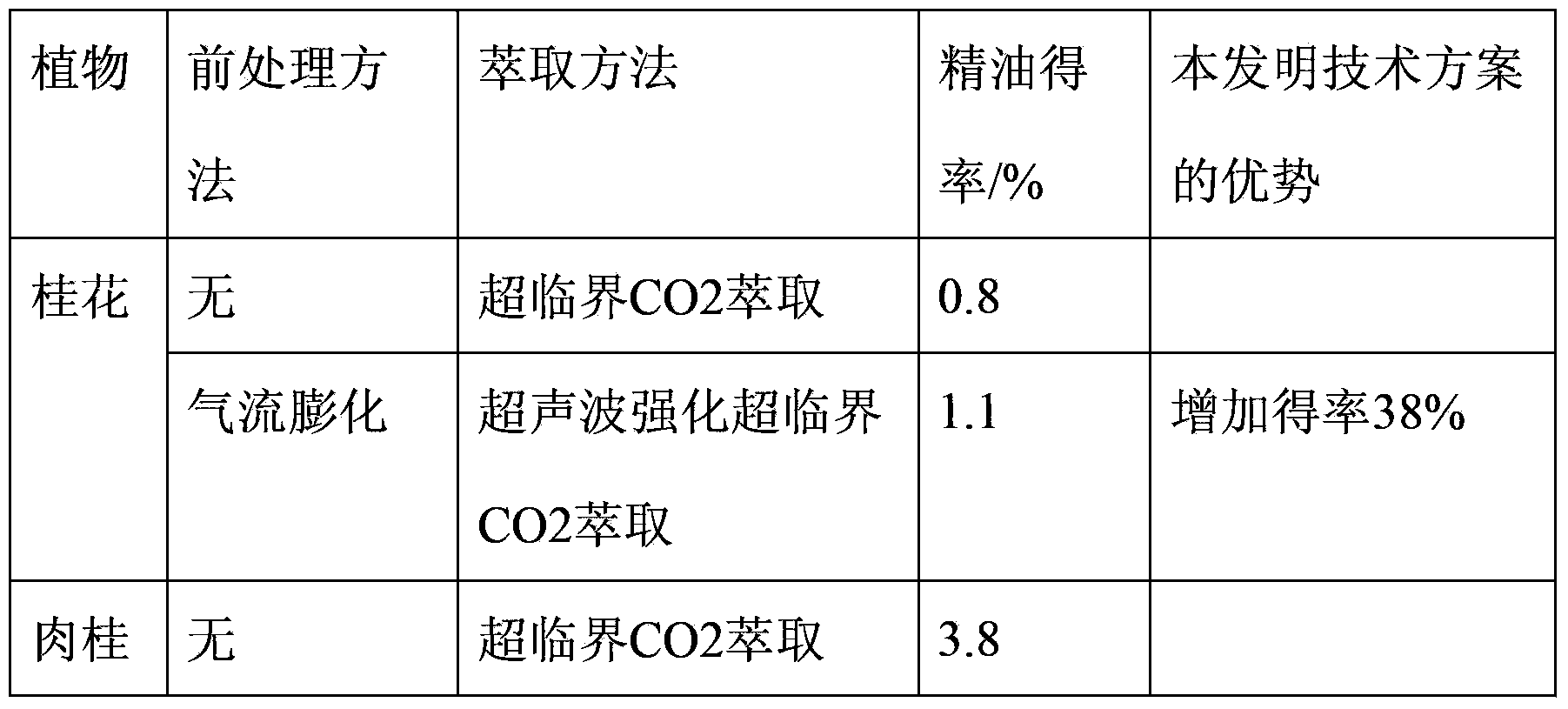

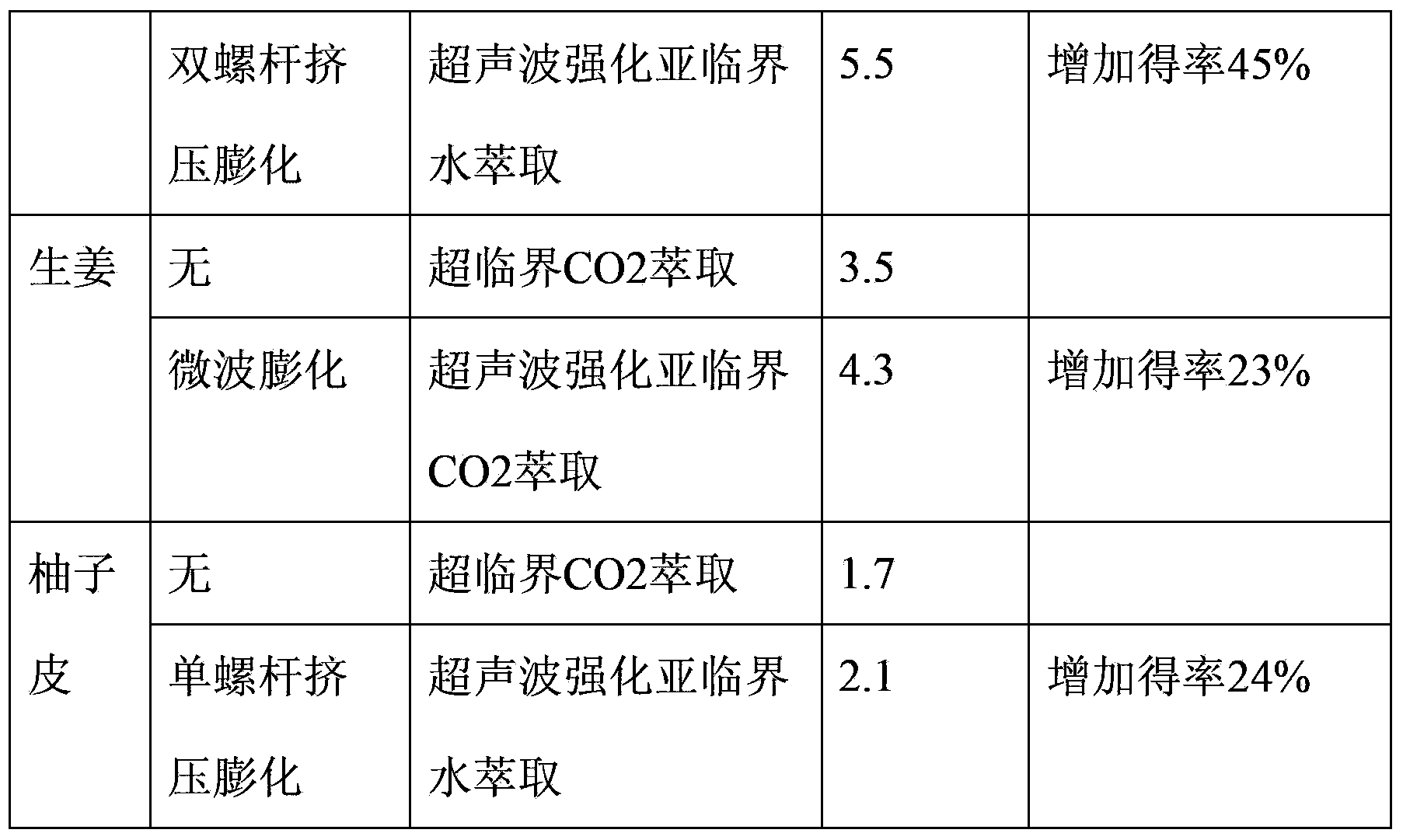

Embodiment 1

[0014] Embodiment 1: choose osmanthus fragrans with good quality and no rot and deterioration as raw material; add 10% cornstarch by weight of raw material, adjust the water content of the mixture at 20wt%, beat and stir evenly; adopt air-flow puffing technology, operating temperature 70 ℃, puffing pressure The difference is 300kPa, and the puffing time is 60min. The mixture is puffed after being processed, then powdered, and passed through a 20-mesh sieve; supercritical CO 2 Extraction, supercritical operating pressure 30MPa, temperature 40°C, extraction time 60min, ultrasonic wave is added at the same time to enhance the extraction effect, ultrasonic power density is 150W / L, ultrasonic frequency is 20kHz, ultrasonic irradiation mode is 10s / 10s (ultrasonic continuous irradiation Time / ultrasound interval time), to obtain essential oil components; the plant and starch mixture after extracting essential oils can be used as feed.

Embodiment 2

[0015] Embodiment two: choose good quality, no rotten cinnamon as raw material; add cassava starch of 20% of raw material weight, adjust the moisture content of the mixture at 25wt%, beating, stirring evenly; adopt twin-screw extrusion expansion technology, screw speed 200r / min, the extrusion temperature is 130°C, the feeding speed is 20r / min, the mixture is extruded after treatment, then powdered, and passed through a 40-mesh sieve; subcritical water extraction is used, the extraction pressure is 15MPa, the extraction temperature is 120°C, and the extraction time is 40min. Ultrasound is added to enhance the extraction effect at the same time as the extraction. The ultrasonic power density is 250W / L, the ultrasonic frequency is 25kHz, and the ultrasonic irradiation method is 5s / 5s (ultrasonic continuous irradiation time / ultrasonic intermittent time), to obtain essential oil components; after extracting essential oils, plants, Starch mixture can be used as feed.

Embodiment 3

[0017] Choose ginger with good quality and no rot and deterioration as raw material; add 15% wheat starch by weight of raw material, adjust the water content of the mixture to 22%, beat and stir evenly; adopt microwave puffing technology, microwave power 1500w, processing time 2min, make the mixture pass through After treatment, it is expanded, then powdered, and passed through a 60-mesh sieve; using subcritical CO 2 Extraction, extraction pressure 12MPa, temperature 25°C, extraction time 30min, ultrasonic power density 200W / L, ultrasonic frequency 20kHz, ultrasonic irradiation mode 8s / 8s (ultrasonic continuous irradiation time / Ultrasonic intermittent time) to obtain essential oil components; the plant and starch mixture after extracting essential oils can be used as feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com