Low temperature synthesis method of non-agglomerated fully stable cubic phase nano-zirconia powder

A technology of nano zirconia and synthesis method, applied in zirconia, nanotechnology, nanotechnology and other directions, can solve the problems of hard agglomeration, large consumption of decomposition reagents, reduced product performance, etc., achieves low energy consumption, and is conducive to cost control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

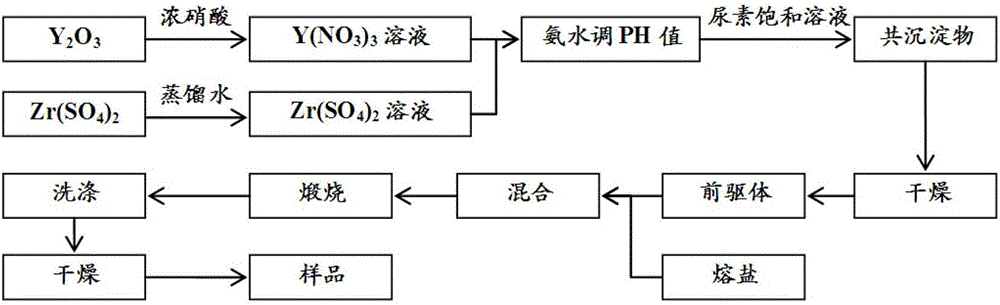

Method used

Image

Examples

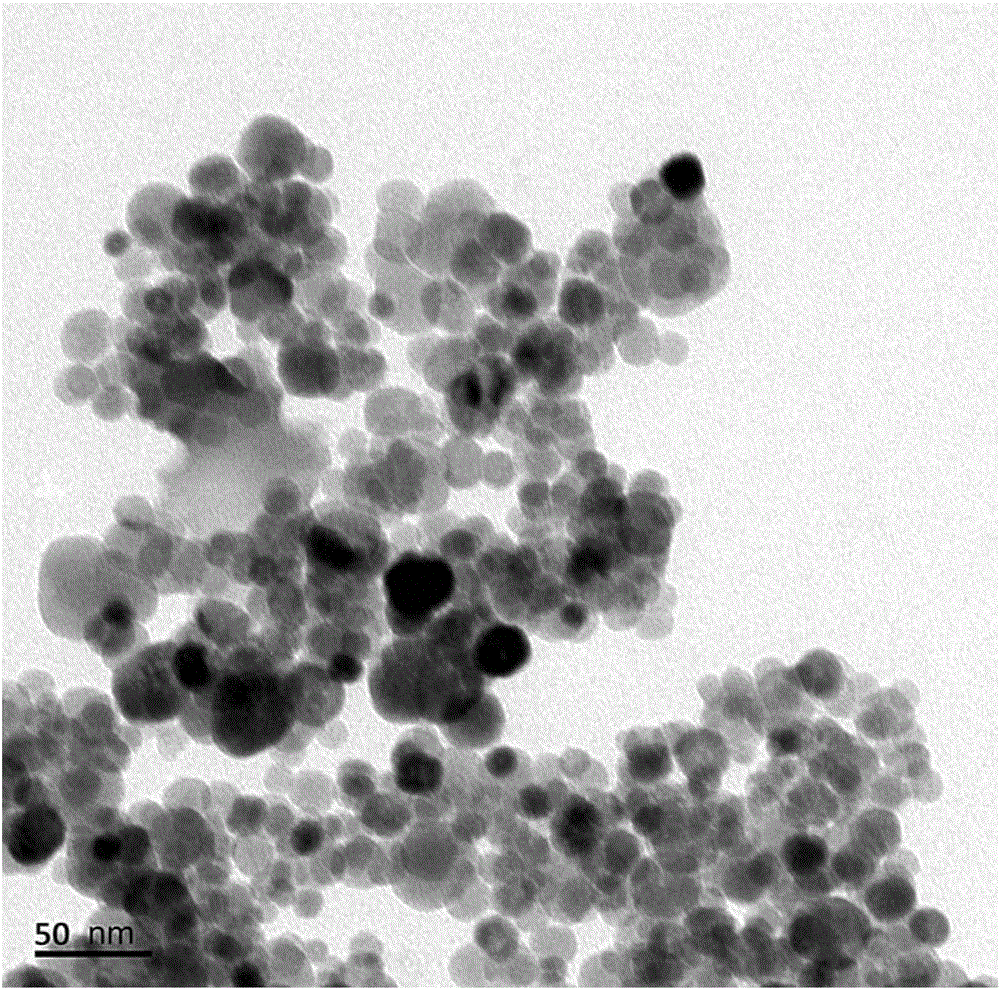

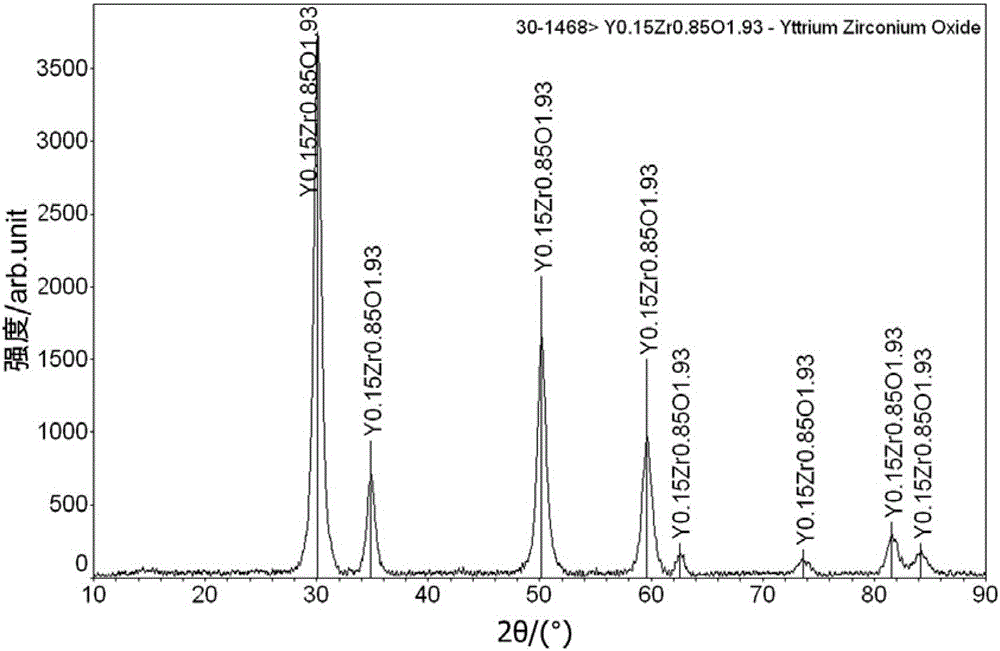

example 1

[0015] First set Y 2 o 3 Dissolve with concentrated nitric acid to form 0.2mol l -1 Stable and transparent Y(NO 3 ) 3 solution. At the same time, zirconium sulfate was dissolved in distilled water to form 0.2mol·l - 1 Stable clear solution. Then the above two solutions according to Y 3+ :Zr 4+ The molar ratio is 3:97 for mixing, and the pH value is adjusted to about 7 with ammonia water. Add a slightly excess saturated urea solution, and heat to about 75°C to form a uniform and stable mixed precipitate (ie precursor). Then the obtained precursor is dried and ground for future use. Will KNO 3 KNO in mass ratio with precursor powder 3 / precursor = 3:1 for proportioning, and introduce about 1wt% of KCl to mix, dry, and place in a ceramic crucible for calcination at about 600°C. After heat preservation for about 1 hour, the crucible is taken out, and the obtained product is washed repeatedly with distilled water, and after drying, a fully stable cubic phase nano-zirco...

example 2

[0017] First set Y 2 o 3 Dissolve with concentrated nitric acid to form 0.2mol l -1 Stable and transparent Y(NO 3 ) 3 solution. Simultaneously ZrOCl 2 ·8H 2 O is dissolved in distilled water to form 0.2mol l -1 Stable clear solution. Then the two solutions were combined according to Y 3+ :Zr 4+ The molar ratio is 3:97 for mixing, and the pH value is adjusted to about 7 with ammonia water. Add a slightly excess saturated urea solution, and heat to about 75°C to form a uniform and stable mixed precipitate (ie precursor). Then the obtained precursor is dried and ground for future use. KOH-KNO 3 Composite molten salt (KOH:KNO 3 The molar ratio is 0.313:0.687) and the precursor powder are compound molten salt according to the mass ratio: precursor = 3:1 for proportioning, and introduce about 1wt% of KCl to mix, dry, and hold in a ceramic crucible at 500 ° C Calcination is carried out left and right. After heat preservation for about 1 hour, the crucible is taken out,...

example 3

[0019] First set Y 2 o 3 Dissolve with concentrated nitric acid to form 0.2mol l -1 Stable and transparent Y(NO 3 ) 3 solution. Simultaneously ZrOCl 2 ·8H 2 O is dissolved in distilled water to form 0.2mol l -1 Stable clear solution. Then the two solutions were mixed according to (Y 3+ :Zr 4+ ) molar ratio of 3:97 for mixing, and adding 4mol l -1 KOH solution, adjust the pH value to about 10 to form a uniform and stable mixed precipitate (ie precursor). Then the obtained precursor is dried and ground for future use. KOH-KNO 3 Composite molten salt (KOH:KNO 3 The molar ratio is 0.313:0.687) and the precursor powder are mixed and dried at a mass ratio of composite molten salt: precursor = 3:1, and placed in a ceramic crucible for calcination at about 500°C. After heat preservation for about 1 hour, the crucible is taken out, and the obtained product is washed repeatedly with distilled water, and after drying, a fully stable cubic phase nano-zirconia powder with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com