Touch drive circuit, optical embedded touch screen and display device

A touch drive circuit and driver technology, which is applied in electrical digital data processing, instruments, calculations, etc., can solve problems such as affecting the accuracy of touch screen touch signal detection, increasing touch screen wiring area, and signal crosstalk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

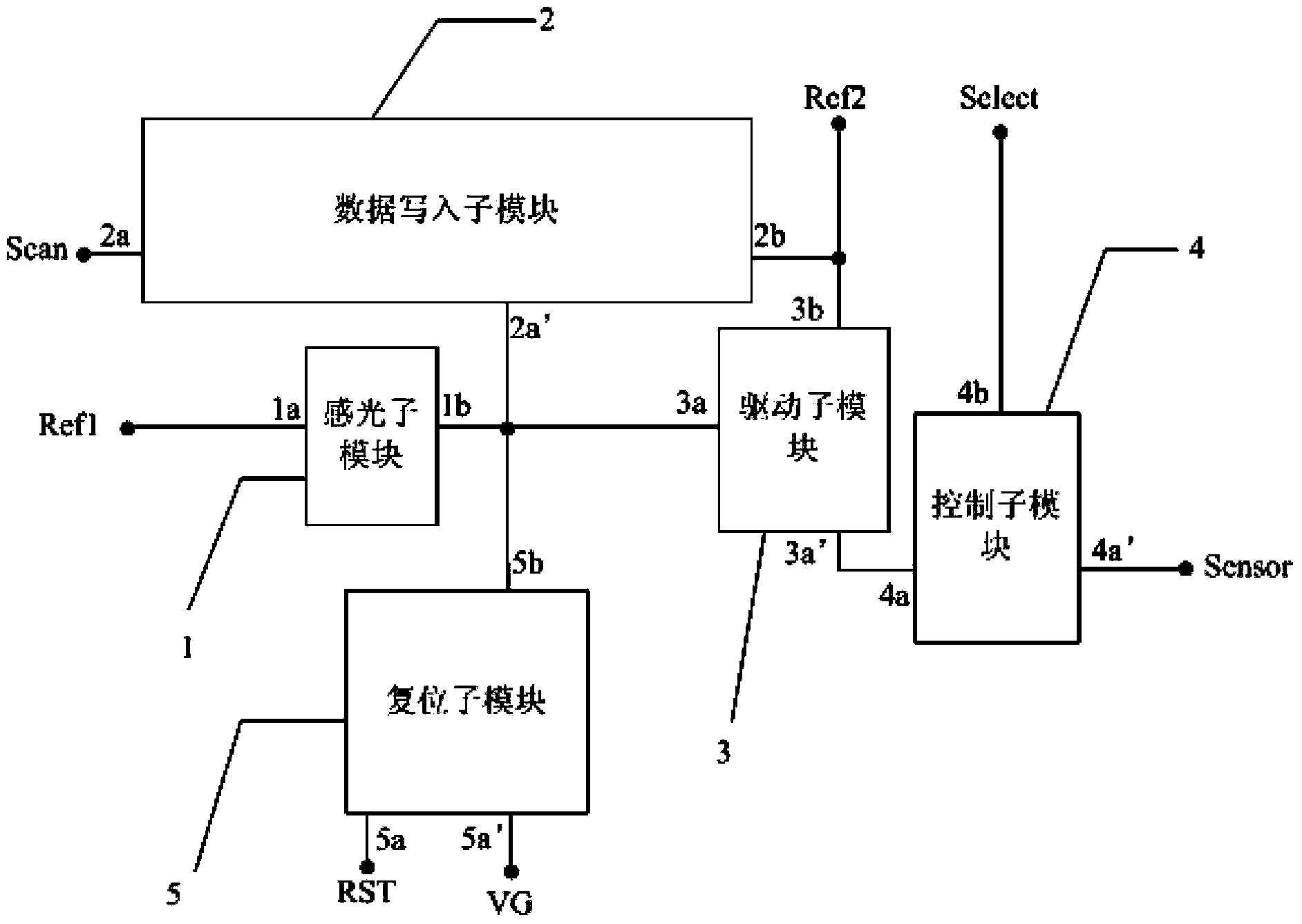

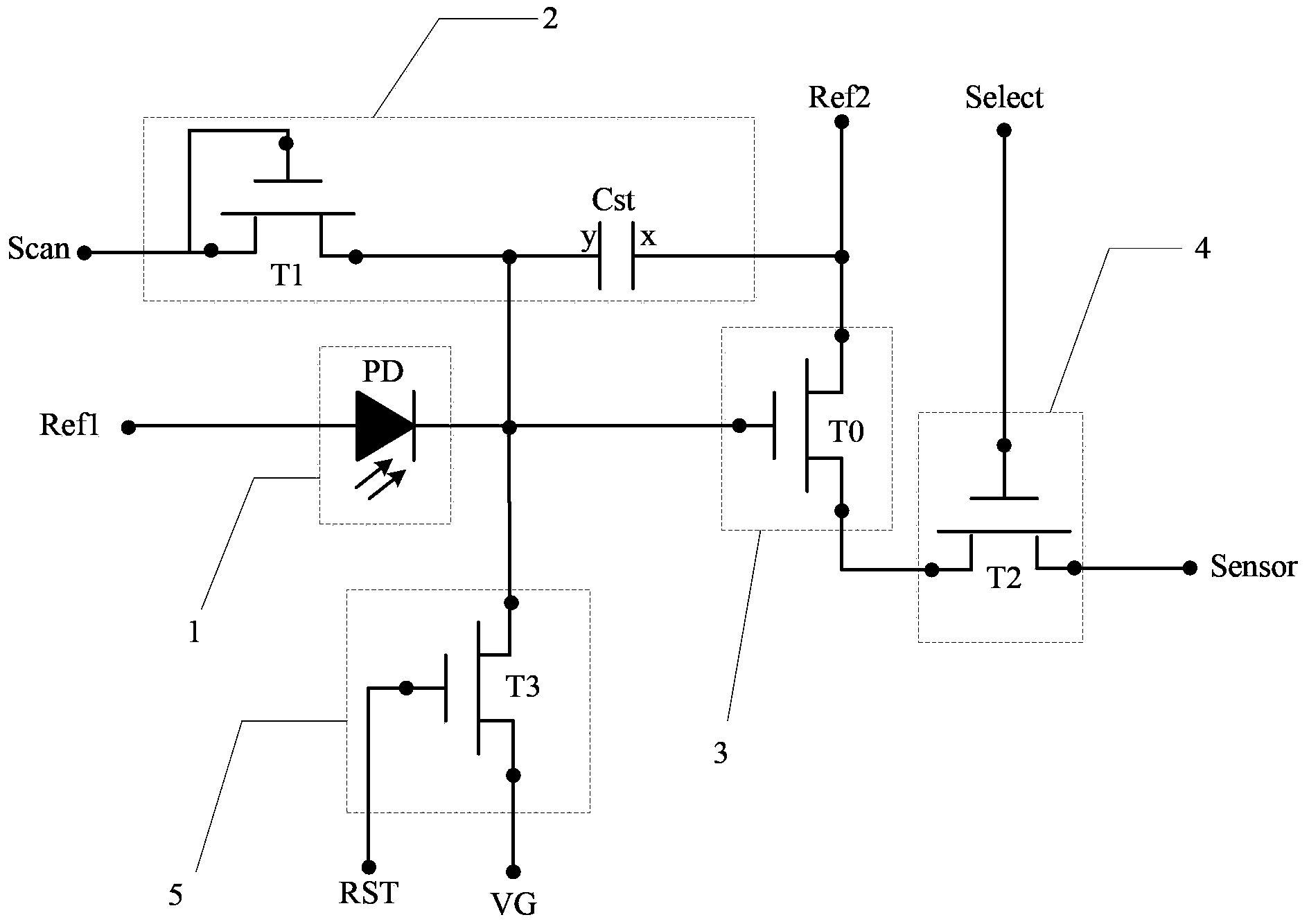

[0054] Such as Figure 2a As shown, the drive transistor T0 , the first switch transistor T1 , the second switch transistor T2 and the third switch transistor T3 are all N-type transistors. Figure 3a for Figure 2a The timing diagram of the circuit, where the voltage of the scanning signal terminal is V Scan , the voltage at the reset control signal terminal is V RST , the voltage at the control signal terminal is V Select , the drain of the driving transistor T0 has a voltage of V when there is a touch A1 , the drain of the drive transistor T0 is V when there is no touch A2 , the voltage of the touch signal reading terminal Sensor is V when there is a touch B1 , the voltage of the touch signal reading terminal Sensor is V when there is no touch B2 .

[0055] Specifically, the working principle of the touch driving circuit is as follows:

[0056] The first stage 1: Scan the voltage V of the signal terminal Scan In high level, reset the voltage V of the control signal...

example 2

[0063] Such as Figure 2b As shown, the driving transistor T0 and the first switch transistor T1 are N-type transistors, and the second switch transistor T2 and the third switch transistor T3 are P-type transistors. Figure 3b for Figure 2b The timing diagram of the circuit, where the voltage of the scanning signal terminal is V Scan , the voltage at the reset control signal terminal is V RST , the voltage at the control signal terminal is V Select , the drain of the driving transistor T0 has a voltage of V when there is a touch A1 , the drain of the drive transistor T0 is V when there is no touch A2 , the voltage of the touch signal reading terminal Sensor is V when there is a touch B1 , the voltage of the touch signal reading terminal Sensor is V when there is no touch B2 .

[0064] Specifically, the working principle of the touch driving circuit is as follows:

[0065] The first stage 1: Scan the voltage V of the signal terminal Scan , Reset control signal termina...

example 3

[0072] Such as Figure 2c As shown, the driving transistor T0, the first switching transistor T1, the second switching transistor T2 and the third switching transistor T3 are all P-type transistors. Figure 3c for Figure 2c The timing diagram of the circuit, where the voltage of the scanning signal terminal is V Scan , the voltage at the reset control signal terminal is V RST , the voltage at the control signal terminal is V Select , the drain of the driving transistor T0 has a voltage of V when there is a touch A1 , the drain of the drive transistor T0 is V when there is no touch A2 , the voltage of the touch signal reading terminal Sensor is V when there is a touch B1 , the voltage of the touch signal reading terminal Sensor is V when there is no touch B2 .

[0073] Specifically, the working principle of the touch driving circuit is as follows:

[0074] The first stage 1: Scan the voltage V of the signal terminal Scan At low level, reset the voltage V of the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com