LED lamp

A technology of LED lamps and LED light sources, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, point light sources, etc., can solve the problem that the light distribution effect and light spots cannot meet the lighting design, the cost of LED light sources increases, the current and Increased power consumption and other issues, to achieve the effects of rapid heat conduction and heat dissipation, low production cost, low power consumption and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

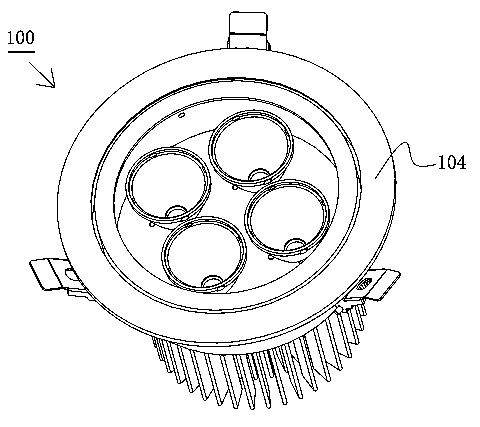

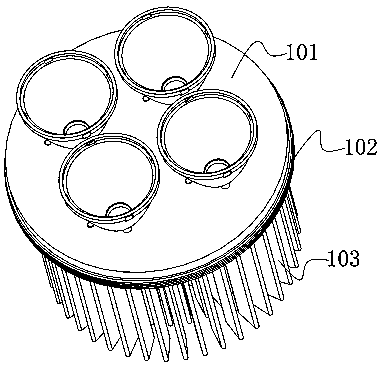

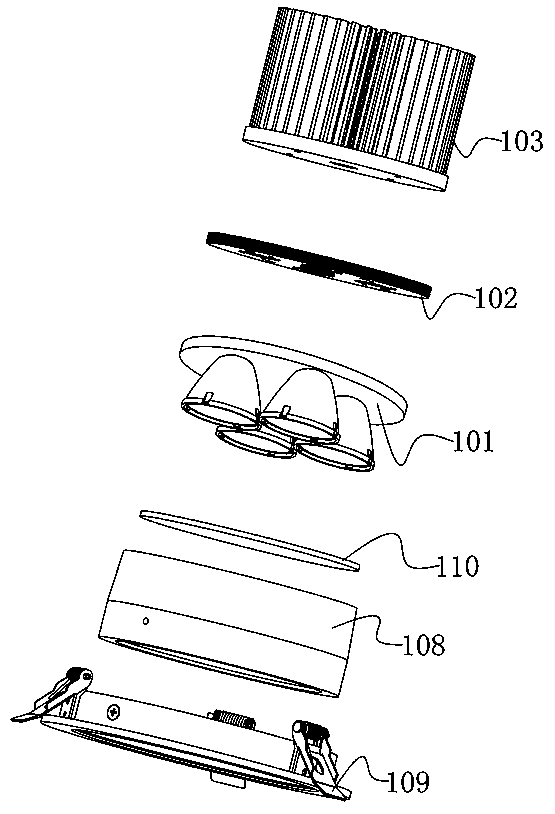

[0030] Such as Figure 1 to Figure 4 As shown, an LED lamp 100 of the present invention includes a light distribution device 101, a heat conduction plate 102, a heat sink 103 and a housing 104, the light distribution device 101 is arranged on one side of the heat conduction plate 102, and the heat sink 103 is set On the other side of the heat conducting plate 102 , the housing 104 covers the light distribution device 101 .

[0031] Such as Figure 4 As shown, the light distribution device 101 includes a substrate 105, a reflective cup 106, and an LED light source 107. At least three reflective cups 106 are arranged on the substrate 105, and an LED light source 107 is provided at one end of each reflective cup 106 facing the substrate 105. , forming a joint light distribution of multiple light sources. In this embodiment, there are four reflective cups 106 and four LED light sources 107, wherein the LED light sources 107 are COB LED light sources.

[0032] In this embodiment...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is: as Figure 5 As shown, in this embodiment, the four reflective cups 106 are arranged in a matrix, and are integrally formed by integral injection molding. A fixed structure, such as a plate-like structure, is formed on the side of the reflective cups 106 facing away from the substrate 105. The reflective cups 106 are fixed together, which makes installation, maintenance and replacement operations easier, saves time and labor, saves labor, and reduces production costs.

[0038] Other structures are the same as in Embodiment 1.

[0039] other embodiments

[0040] In other embodiments, the number of reflector cups and LED light sources is not limited to four, but can be reduced to three, or increased to five or more, and the number and arrangement can be adjusted according to the lighting requirements of different occasions. LED light sources are not limited to COB LED light sources, and a single high-power LE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com