A compact multi-layer reflective lighting system

A multi-layer reflection and lighting system technology, applied in the field of optical lighting, can solve the problems of increasing manufacturing cost, unable to produce light spot effect, light intrusion in residential apartments, etc., and achieve the effect of miniaturization in radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects. In the drawings of the following embodiments, the same reference numerals appearing in each drawing represent the same features or components, which can be applied in different embodiments.

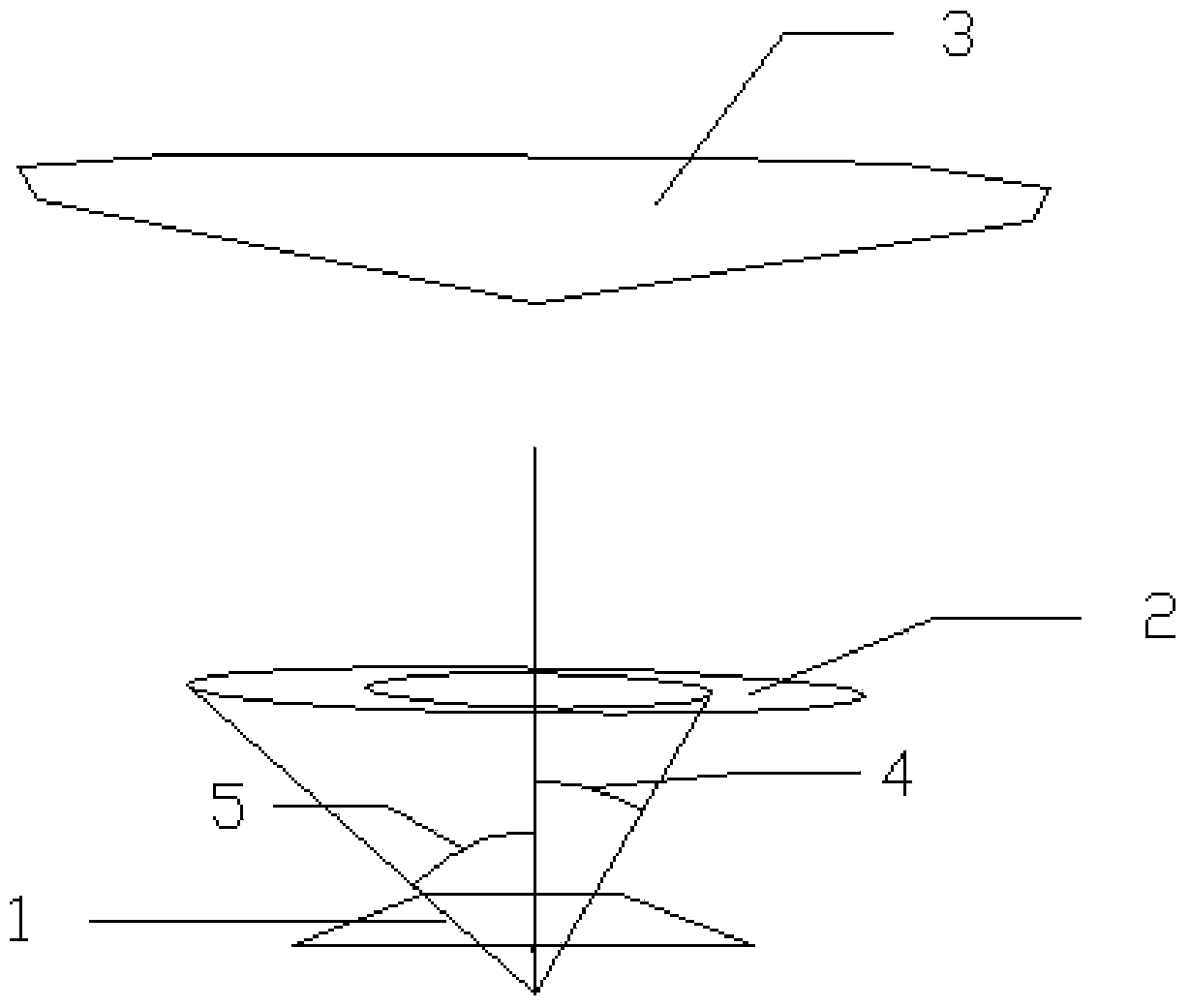

[0018] like figure 1 As shown, a compact multi-layer reflective lighting system includes a light source, a first-layer reflector 1, a middle-layer reflector 2, and a top-layer reflector 3 from bottom to top; the middle-layer reflector 2 is one or more, the first layer reflector 1 and the middle layer reflector 2 are both hollow ring structures, and the top layer reflector 3 is a circular structure;

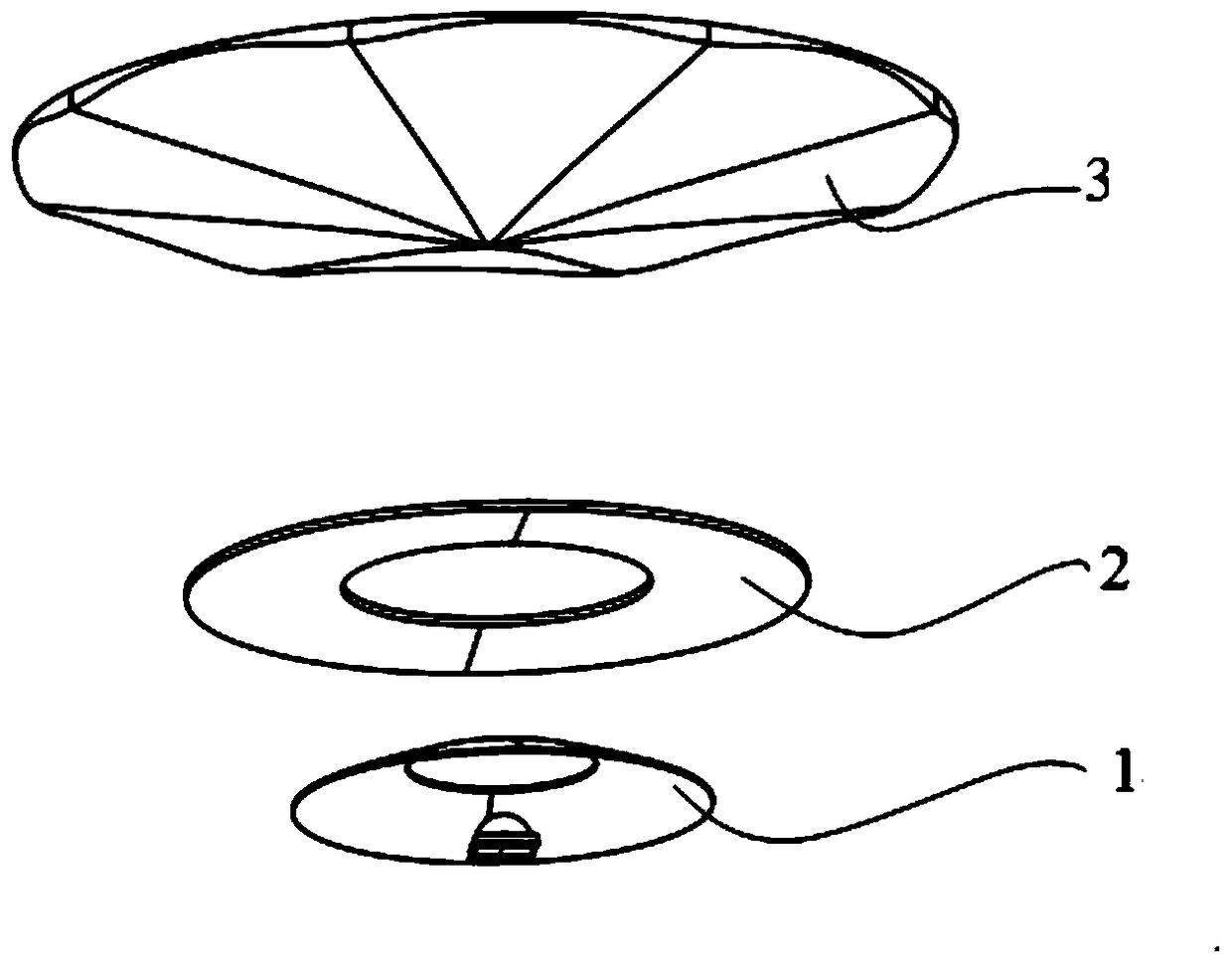

[0019] like figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com