Method for improving electrolyte viscosity of aluminum reduction cell

An aluminum electrolytic cell and electrolyte technology, which is applied in the field of electrolytic aluminum, can solve problems such as affecting current efficiency and stable production, unbalanced control of alumina concentration, and difficulty in discharging anode gas, reducing the phenomenon of shell head and bag, improving production stability, The effect of avoiding the phenomenon of alumina concentration imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be described in detail below in conjunction with the examples.

[0019] Take the 180KA aluminum electrolytic cell as an example:

[0020] 1. Adjustment of process technical conditions:

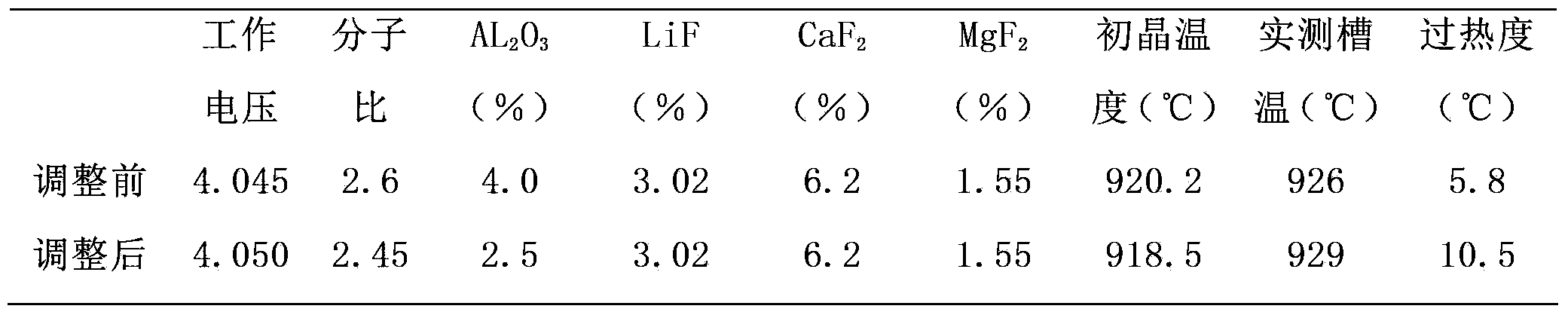

[0021] A representative tank A is selected as the implementation tank. In this tank, the electrolyte is sticky, the electrolyte is splashed at the aluminum outlet and the ignition hole of the blanking, and the sudden effect and the shell head bag increase. After analysis, the molecular ratio of the tank is high (2.6), the concentration of alumina is high (4.0%), and the degree of superheat is low (5.8°C). According to the above analysis, make the following adjustments to the tank parameters:

[0022] 1) Increase the working voltage by 5mv to 4.050V; and strengthen the insulation of the electrolytic cell to reduce heat loss;

[0023] 2) Increase the amount of aluminum fluoride added and reduce the molecular ratio to 2.45;

[0024] 3) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com