Preparation method for modified dicyandiamide-formaldehyde flocculating agent and application of flocculating agent product

A technology of dicyandiamide formaldehyde and flocculants, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, textile industry wastewater treatment, etc., can solve problems such as difficult operation and difficult industrial production, and achieve simple process and easy The effect of mild operation and reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

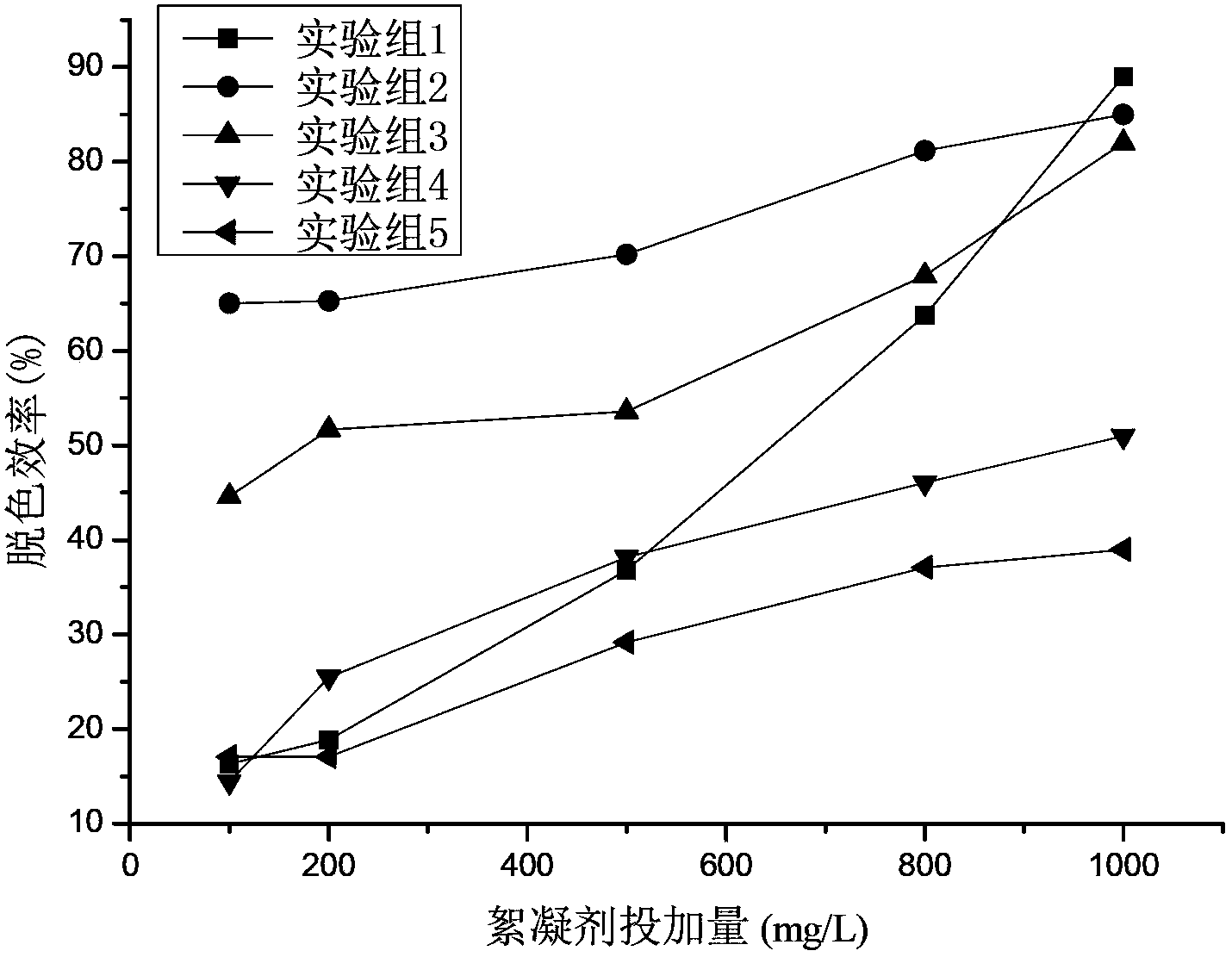

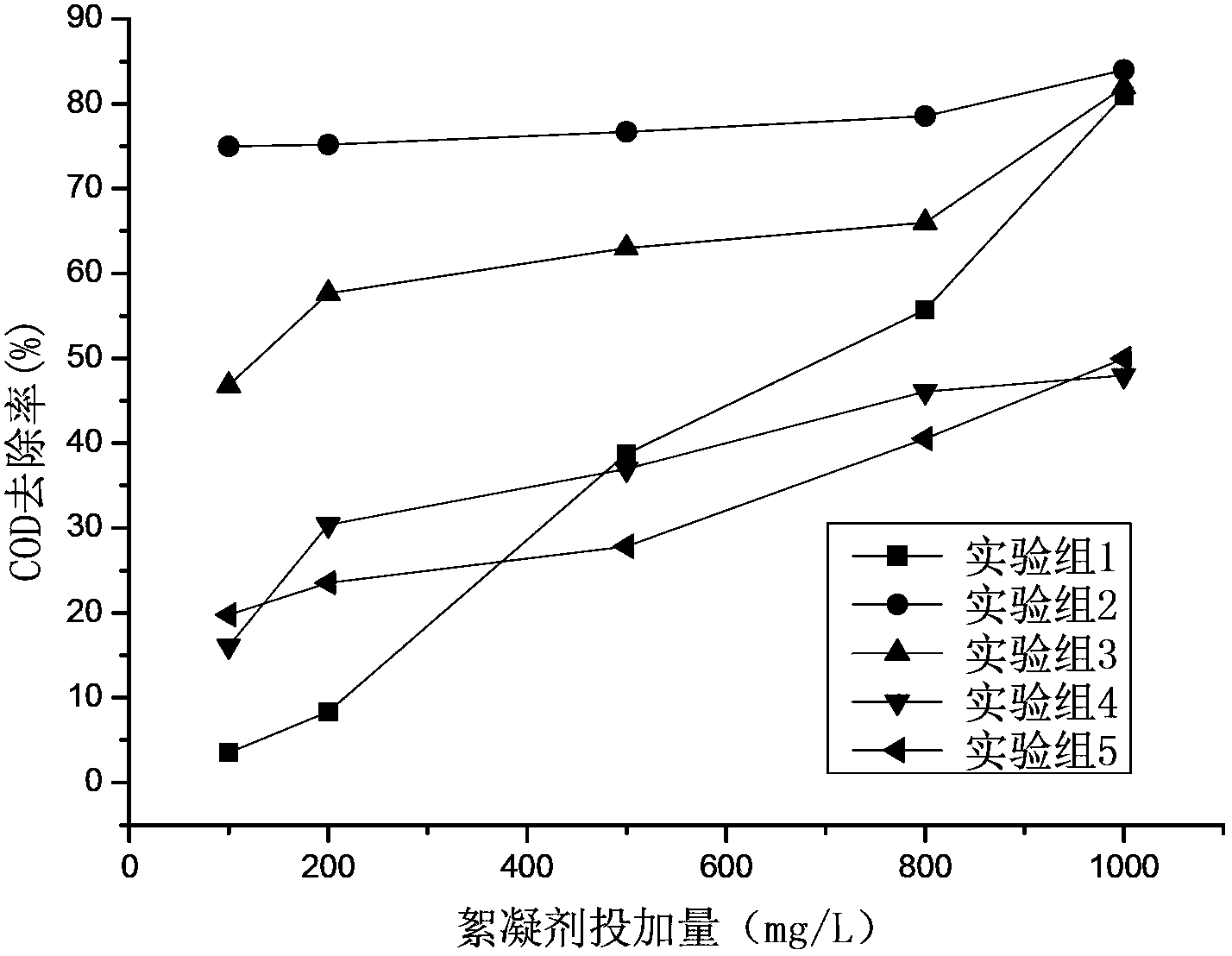

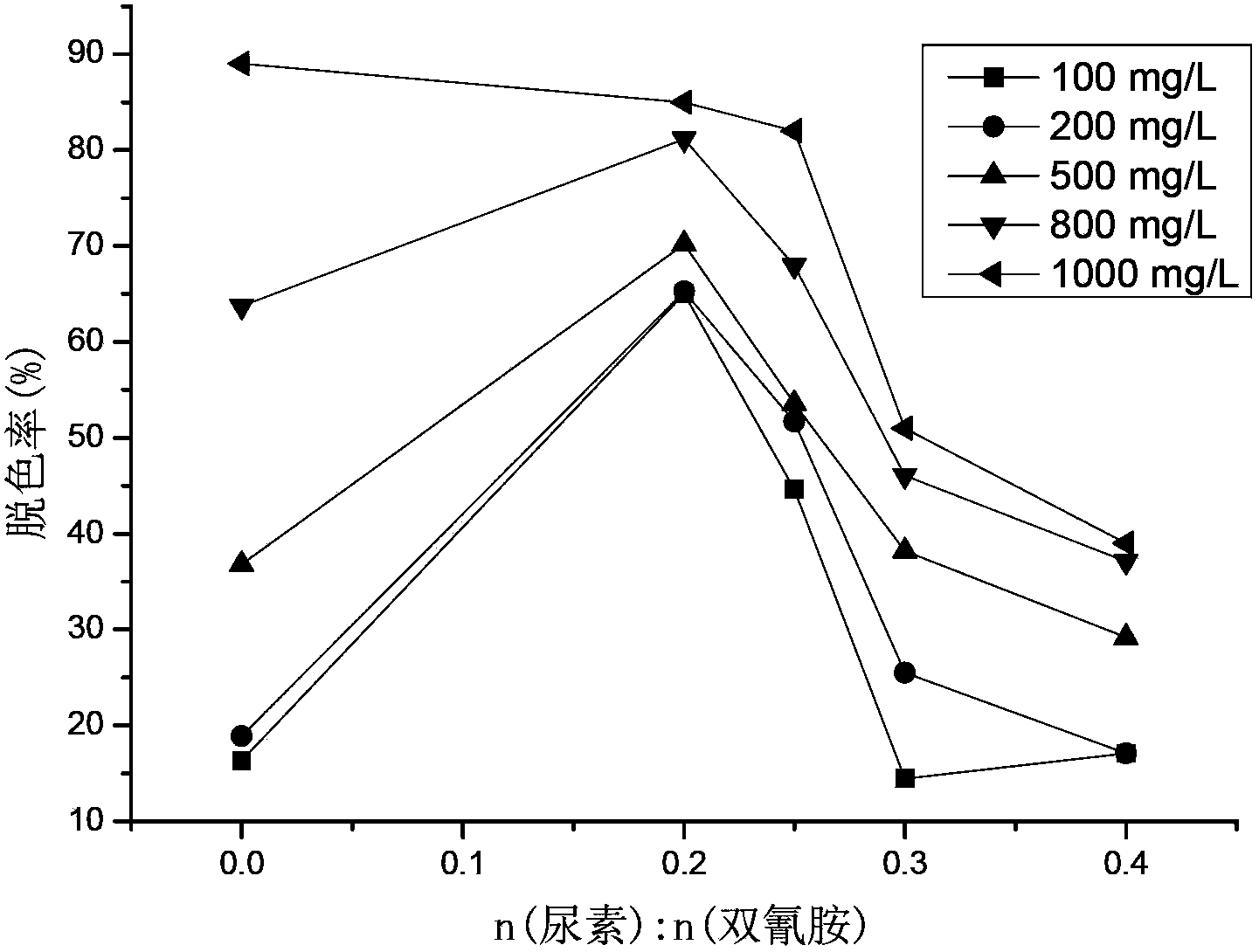

Embodiment 1

[0025] Add 0.7 mol of formaldehyde, 0.5 mol of dicyandiamide and 0.1 mol of urea into the reactor, then raise the temperature to 40°C, then add 0.036 mol of aluminum chloride, after the addition, control the temperature at 40 ℃ for 20min~30min; after the reaction, add 0.2mol of the remaining formaldehyde, so that the molar ratio of the raw material dicyandiamide to the total amount of formaldehyde is 1:1.8, then raise the temperature to 45℃, and add 0.72mol of ammonium salt Modifier, the ammonium salt modifier is ammonium chloride, and after controlling the temperature for 30min to 40min, the temperature is raised to 65°C and the reaction is continued for 3 hours. After the reaction, the modified dicyandiamide formaldehyde flocculant is obtained .

Embodiment 2

[0027] Add 0.7 mol of formaldehyde, 0.5 mol of dicyandiamide and 0.125 mol of urea into the reactor, then raise the temperature to 30°C, then add 0.0375 mol of aluminum chloride, after the addition, control the temperature at 30 ℃ for 20min to 30min; after the reaction, add the remaining 0.2375mol of formaldehyde, so that the molar ratio of the raw material dicyandiamide to the total amount of formaldehyde is 1:1.875, then raise the temperature to 45℃, and add 0.75mol of ammonium Salt modifier, the ammonium salt modifier is ammonium chloride, and after controlling the temperature for 30min to 40min, the temperature is raised to 75°C to continue the reaction for 2 hours. After the reaction, the modified dicyandiamide formaldehyde flocculation agent.

Embodiment 3

[0029]Add 0.8 mol of formaldehyde, 0.5 mol of dicyandiamide and 0.150 mol of urea into the reactor, then raise the temperature to 35°C, then add 0.0390 mol of aluminum chloride, after the addition, control the temperature at 35 ℃ for 20min-30min; after the reaction, add the remaining formaldehyde 0.1750mol, make the molar ratio of the raw material dicyandiamide to the total amount of formaldehyde 1:1.95, then raise the temperature to 45℃, add 0.78mol of ammonium Salt modifier, the ammonium salt modifier is ammonium chloride, and after controlling the temperature for 30min to 40min, the temperature is raised to 70°C to continue the reaction for 2.5 hours. After the reaction, the modified dicyandiamide formaldehyde flocculation agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com