High-temperature resistance lithium ion secondary battery adhesive and preparation method thereof

A lithium-ion battery and secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as high temperature resistance, poor acid resistance, poor salt resistance, and easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

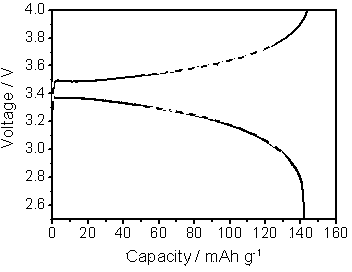

Image

Examples

Embodiment 1

[0018] In the reactor, add 25 parts of 2-acrylamide-2-methylpropanesulfonate lithium, 15 parts of lithium itaconate, 5 parts of maleic anhydride, 1 part of carboxymethylcellulose lithium and 254 parts of distilled water, in The rotating speed is 150 rev / min stirring speed and gradually warming up to 70°C, then adding 0.6 parts of ammonium persulfate initiator to initiate the reaction, the reaction is completed after 1 hour, and the lithium-ion secondary battery positive electrode material with a solid content of 15% is obtained adhesive.

Embodiment 2

[0020] Add 25 parts of lithium 2-acrylamide-2-methylpropanesulfonate, 20 parts of dimethyl itaconate, 5 parts of maleic anhydride, 1 part of lithium carboxymethylcellulose and 254 parts of distilled water into the reactor , gradually warming up to 70°C at a stirring speed of 150 rpm, then adding 0.6 parts of ammonium persulfate initiator to initiate the reaction, and the reaction was completed after 1 hour, and a lithium-ion secondary battery with a solid content of 15% was obtained Cathode material binder.

Embodiment 3

[0022] Add 25 parts of lithium 2-acrylamide-2-methylpropanesulfonate, 20 parts of lithium itaconate, 5 parts of fumaric acid, 2 parts of carboxymethylcellulose lithium and 253 parts of distilled water in the reactor, at a speed of At a stirring speed of 150 rpm, the temperature was gradually raised to 70° C., and then 0.6 parts of ammonium persulfate initiator was added to initiate the reaction. After 1 hour, the reaction was completed, and a lithium-ion secondary battery positive electrode material bonded with a solid content of 15% was obtained. agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com