Heatproof mixing explosive and preparation method thereof

A mixed explosive and heat-resistant technology, which is applied in explosive processing equipment, explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the problems that the armor-piercing power is difficult to meet the exploration needs and the relative density is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

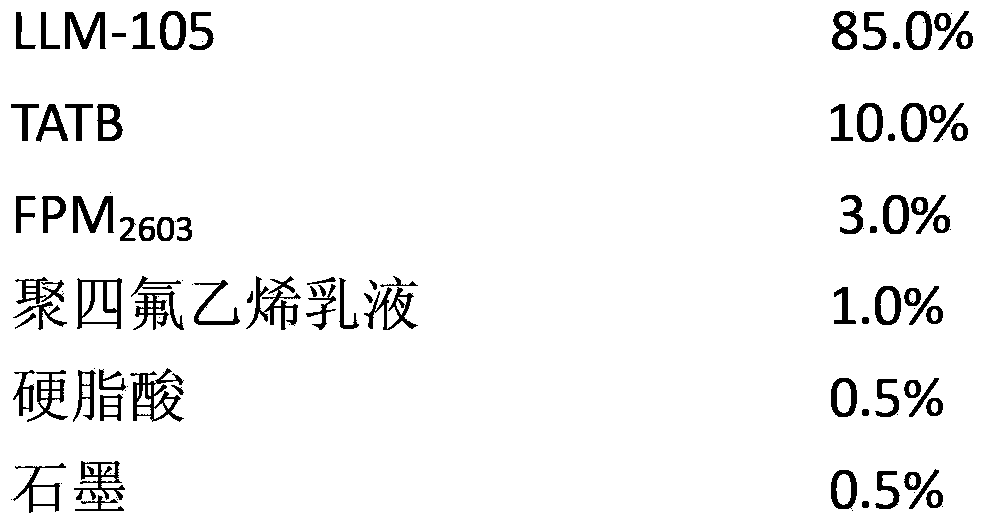

[0035] The heat-resistant mixed explosive of the present embodiment is composed of raw materials according to the following mass percentages:

[0036]

[0037] 1.1 Manufacturing process

[0038] (1) Preparation of solution

[0039] 30gFPM 2603 Add 100ml of ethyl acetate and dissolve under stirring at a temperature of 50°C to obtain FPM 2603 5 g of stearic acid was added into 10 ml of petroleum ether, and dissolved under stirring at a temperature of 45° C. to obtain a stearic acid solution for use.

[0040] (2) Coating of explosives

[0041] Stir 850g LLM-105, 100g TATB and 5g graphite in 2kg water to form a uniform dispersion system suspended in water, and add the prepared FPM to it 2603 ethyl acetate solution, stearic acid solution and polytetrafluoroethylene emulsion with a net content of 10g, and 5g of calcium chloride was added to break the emulsion to obtain an explosive slurry.

[0042] (3) Granulation

[0043] Reflux and evaporate the explosive slurry obtained ...

Embodiment 2

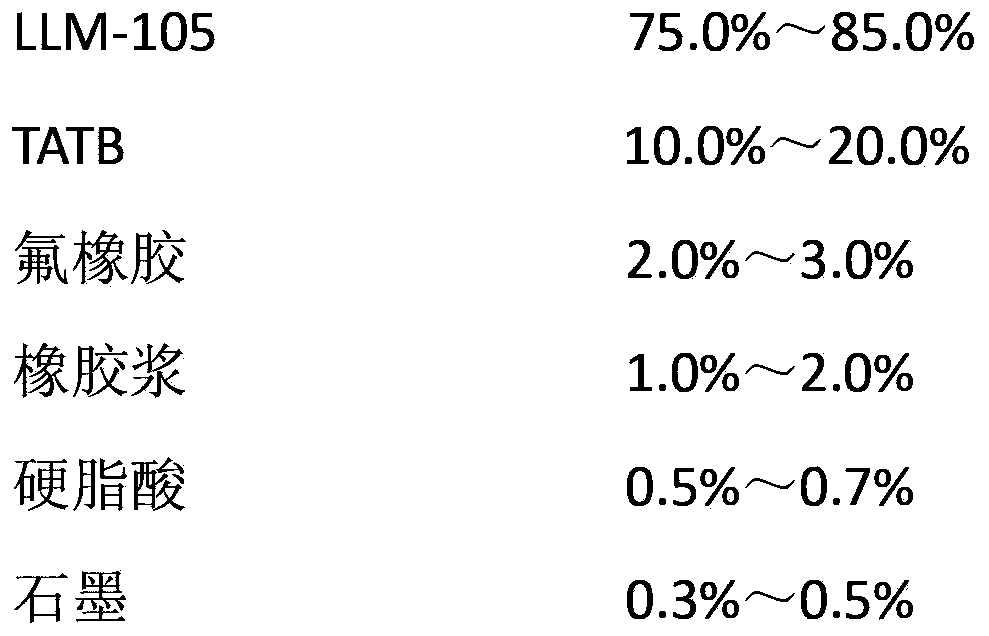

[0054] The heat-resistant mixed explosive of the present embodiment is composed of raw materials according to the following mass percentages:

[0055]

[0056] 2.1 Manufacturing process

[0057] The manufacturing process of this embodiment is the same as that of Embodiment 1, the only difference being the raw materials and proportioning of the explosive.

[0058] 2.2 Performance test

[0059] Table 3 performance test results

[0060]

Embodiment 3

[0062] The heat-resistant mixed explosive of the present embodiment is composed of raw materials according to the following mass percentages:

[0063]

[0064]

[0065] 3.1 Manufacturing process

[0066] The manufacturing process of this embodiment is the same as that of Embodiment 1, the only difference being the raw materials and proportioning of the explosive.

[0067] 3.2 Performance test

[0068] Table 4 performance test results

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com