High-temperature gas cooled reactor and low-temperature multiple-effect distillation seawater desalinization coupling device

A high-temperature gas-cooled reactor, multi-effect distillation technology, applied in seawater treatment, general water supply conservation, water/sewage treatment, etc., can solve problems such as unutilized heat and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

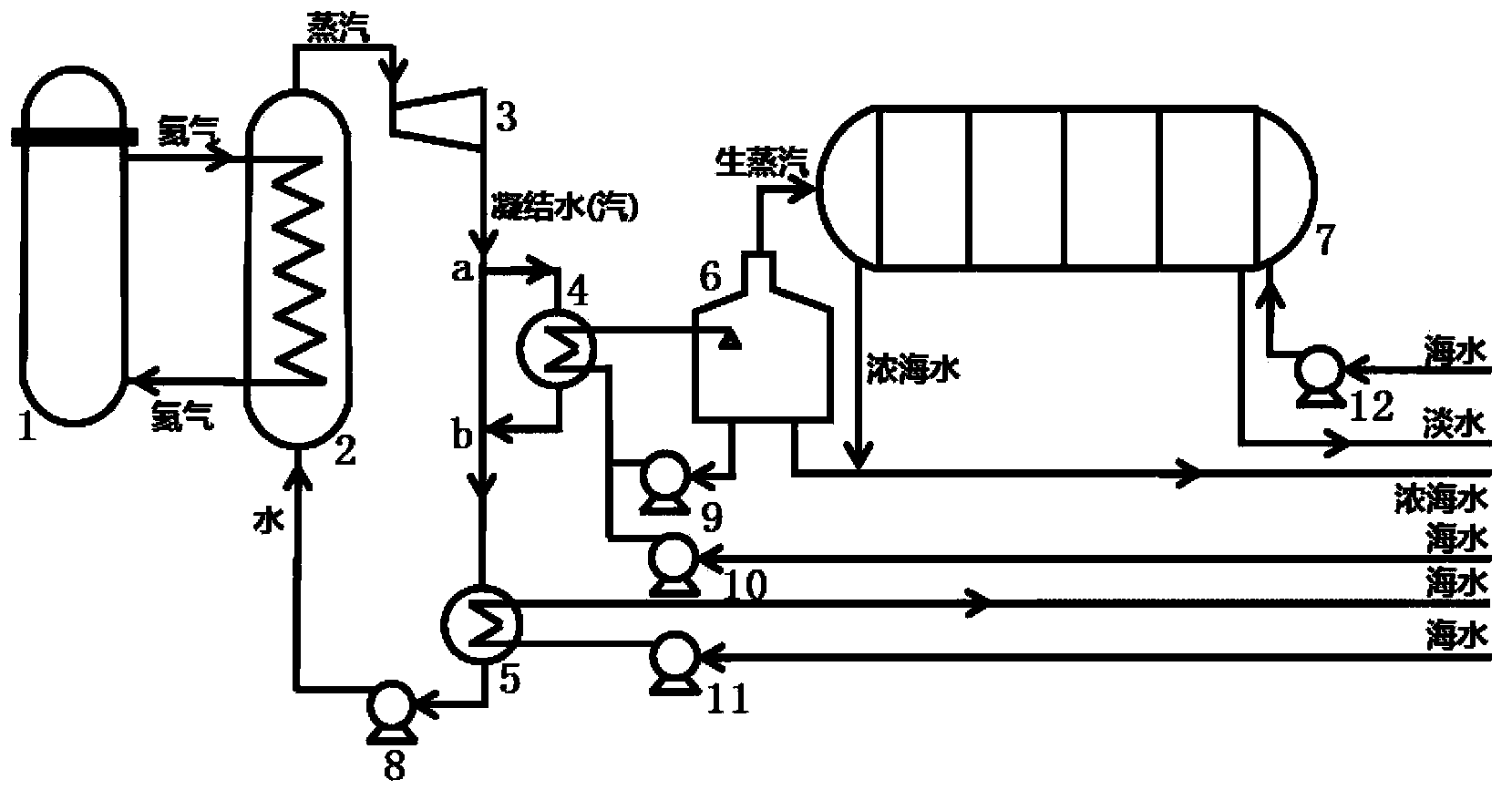

[0013] figure 1 It is a schematic diagram of the connection relationship of the device used in the present invention, refer to figure 1 As shown, the 750°C helium gas in the high-temperature gas-cooled reactor 1 with a total heating power of 500MW exchanges heat with the 205°C main feed water of the steam generator 2 and then cools to 250°C and returns to the high-temperature gas-cooled reactor 1. The main feed water is heated to form a high temperature The high-pressure main steam (540℃, 18MPa, 716t / h) drives the steam turbine 3 to rotate and generate electricity. The electric power is 200MW. After power generation, the flow of 238t / h of the condensed water (steam) flows directly to the condenser 5. The other 478t / h of condensed water (steam) ) Enter the condensing bypass from the inlet a of the bypass pipe, heat the seawater to 99℃ in the condenser 4, and the hot seawater enters the flash tank 6 to flash under reduced pressure to obtain 119t / h of 70℃ raw steam into the subseq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com