Method for preparing antimony sesquioxide by stibnite concentrate

A technology of antimony trioxide and antimony sulfide, which is applied in chemical instruments and methods, inorganic chemistry, antimony compounds, etc., can solve the problems of high whiteness and low whiteness, and achieve the effect of shortening the process flow, avoiding dissolution and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

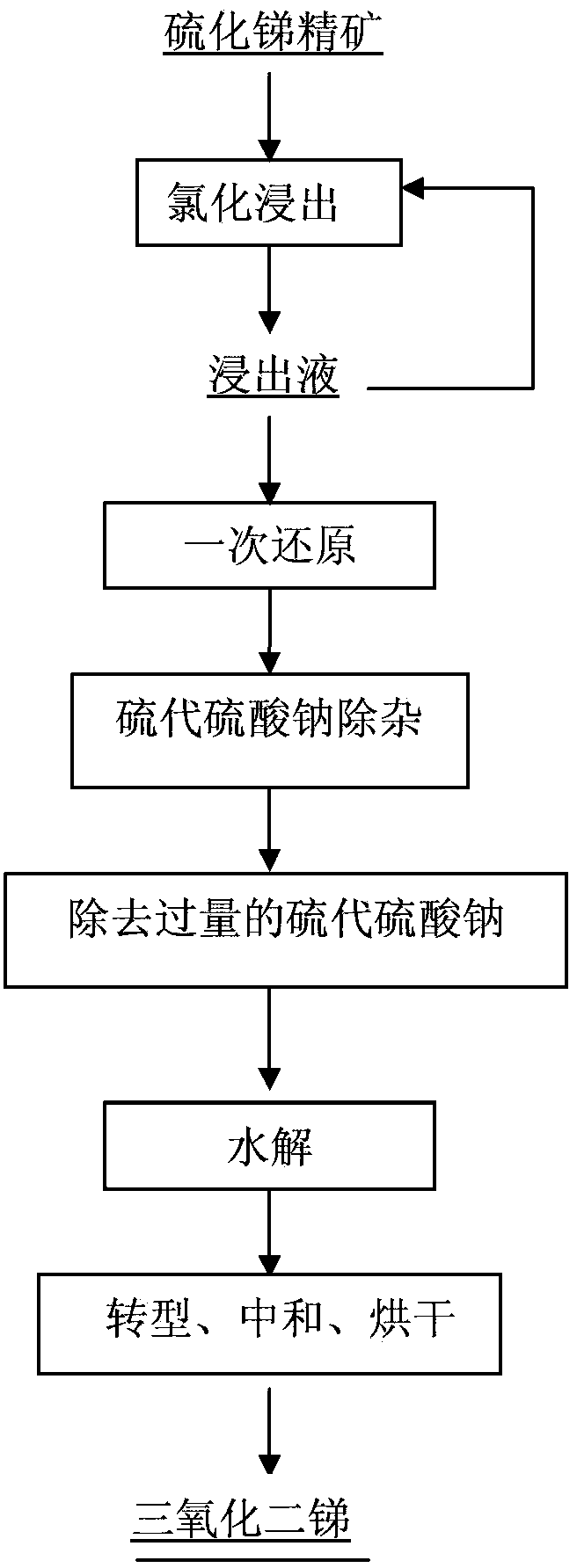

[0035] The flow process that produces in the laboratory of the present invention is as follows:

[0036] Table 1 Contents of main components of a certain mineral source

[0037] Sb%

Pb%

As%

Bi%

Cu%

Aug / t

SiO 2 %

h 2 O%

44.12

0.68

1.00

0.0635

0.570

5.13

17.94

15.68

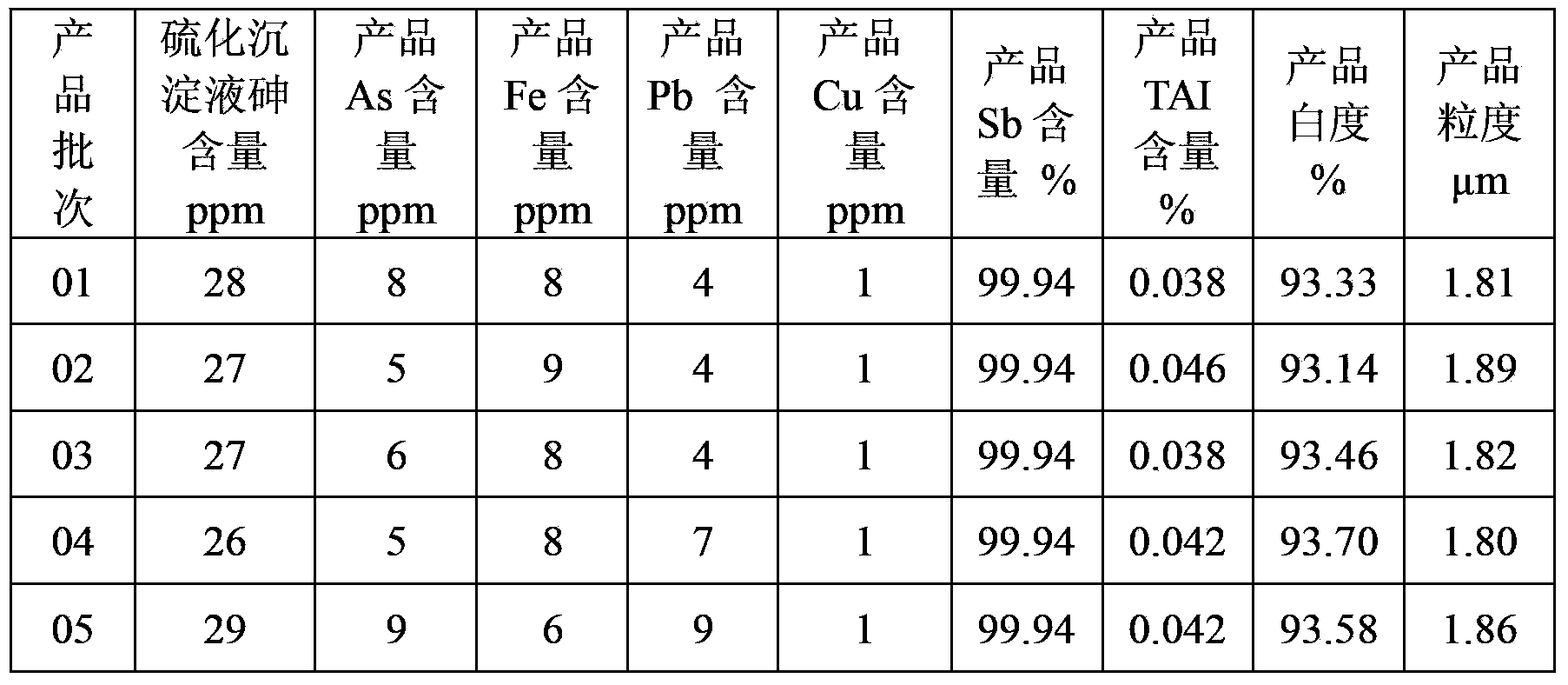

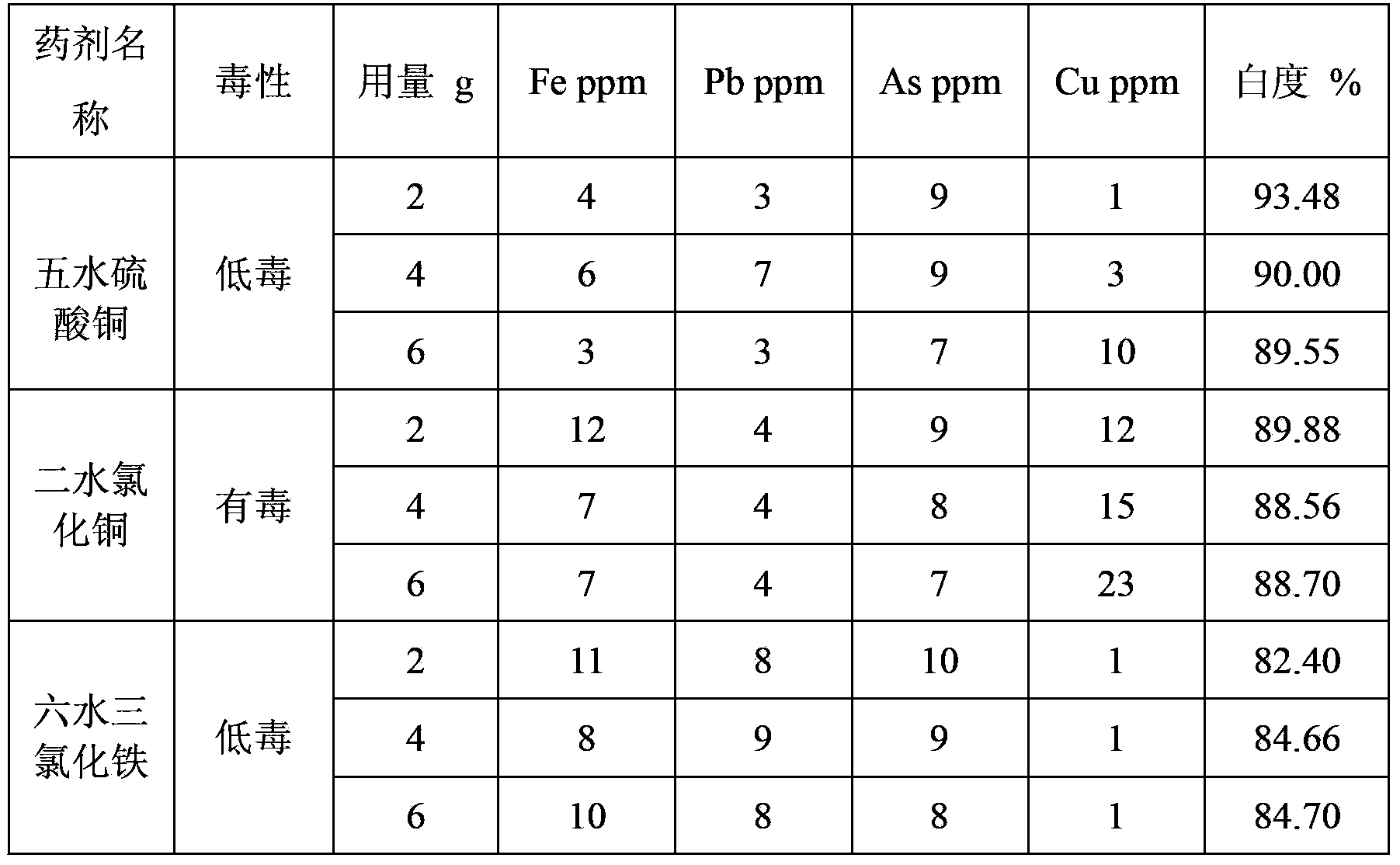

[0038]Add antimony sulfide concentrate to the chlorinated leaching solution of the above-mentioned 80 mesh antimony sulfide concentrate for primary reduction; 10 to 15 times the mass; (sodium thiosulfate is industrial grade, with a main content of 99.96%) to react for 4 to 5 hours. Filter, and the filtrate precipitates for no less than 24 hours. When the arsenic content in the filtrate is within 30ppm, filter, add 0.4-0.8 times the amount of sodium thiosulfate copper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com