Punching machine with automatic feeding function

A technology of automatic feeding and punching machine, used in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low machining accuracy, imperfection, and inability to apply large metal rods, to improve production speed and processing. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

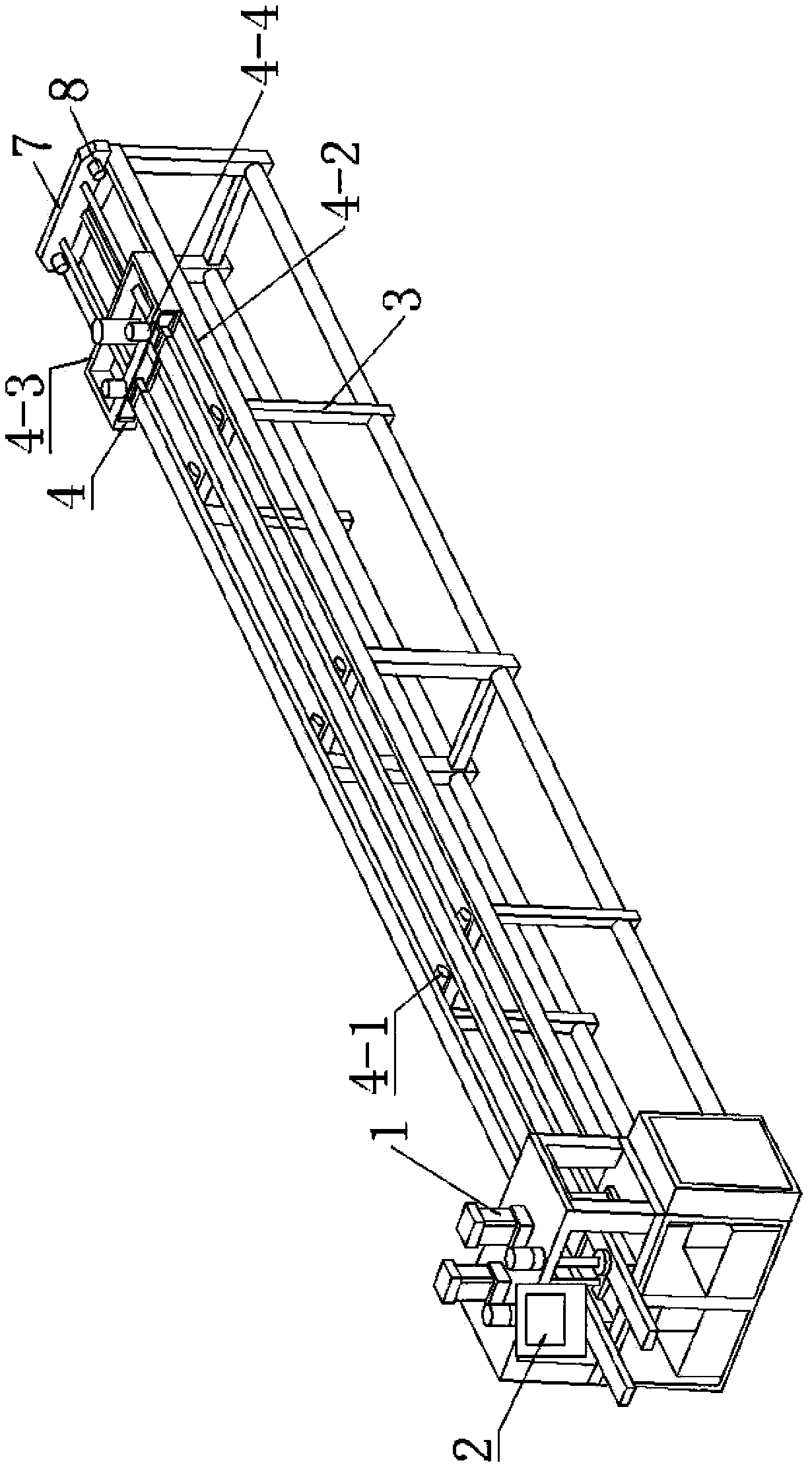

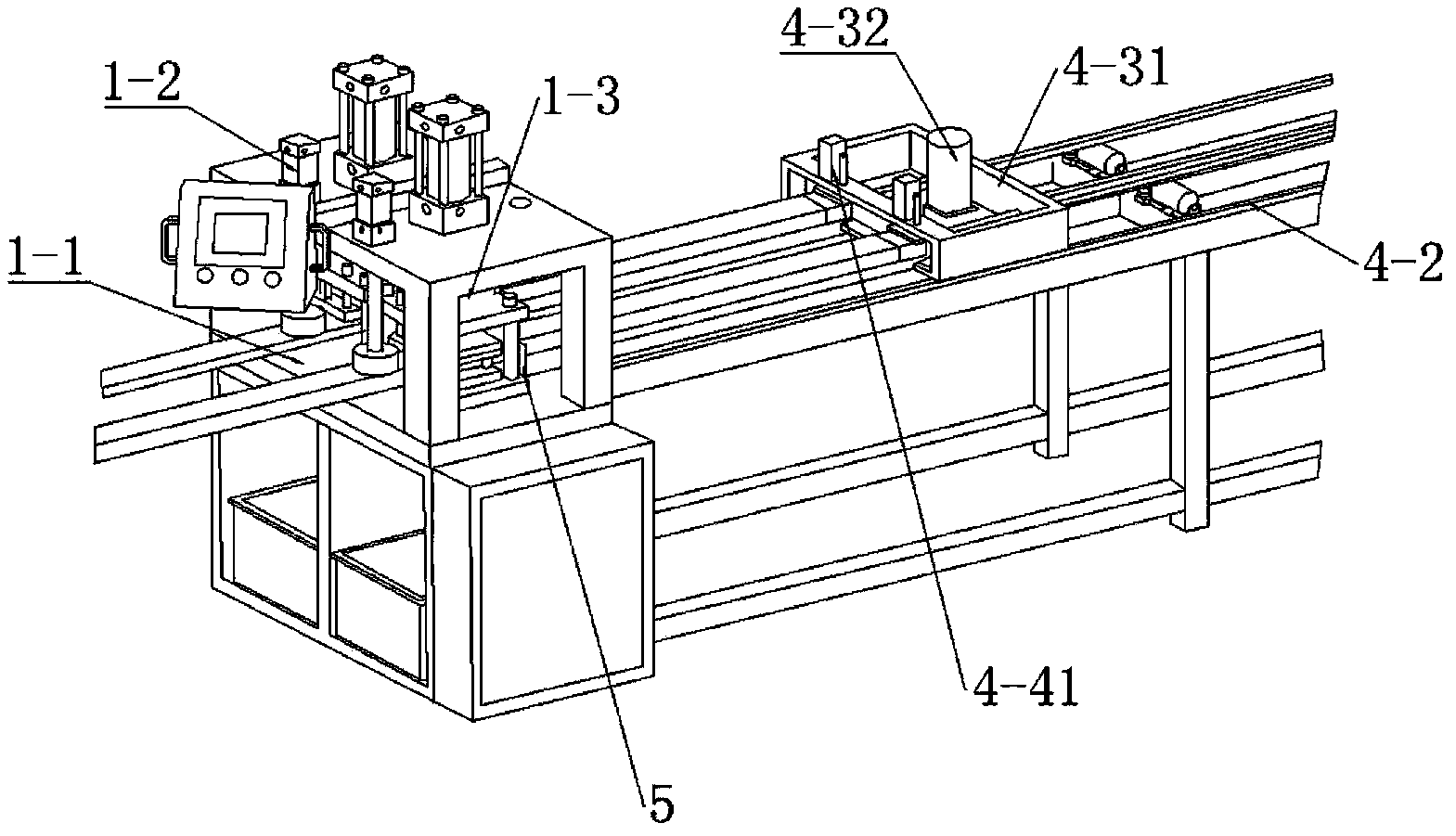

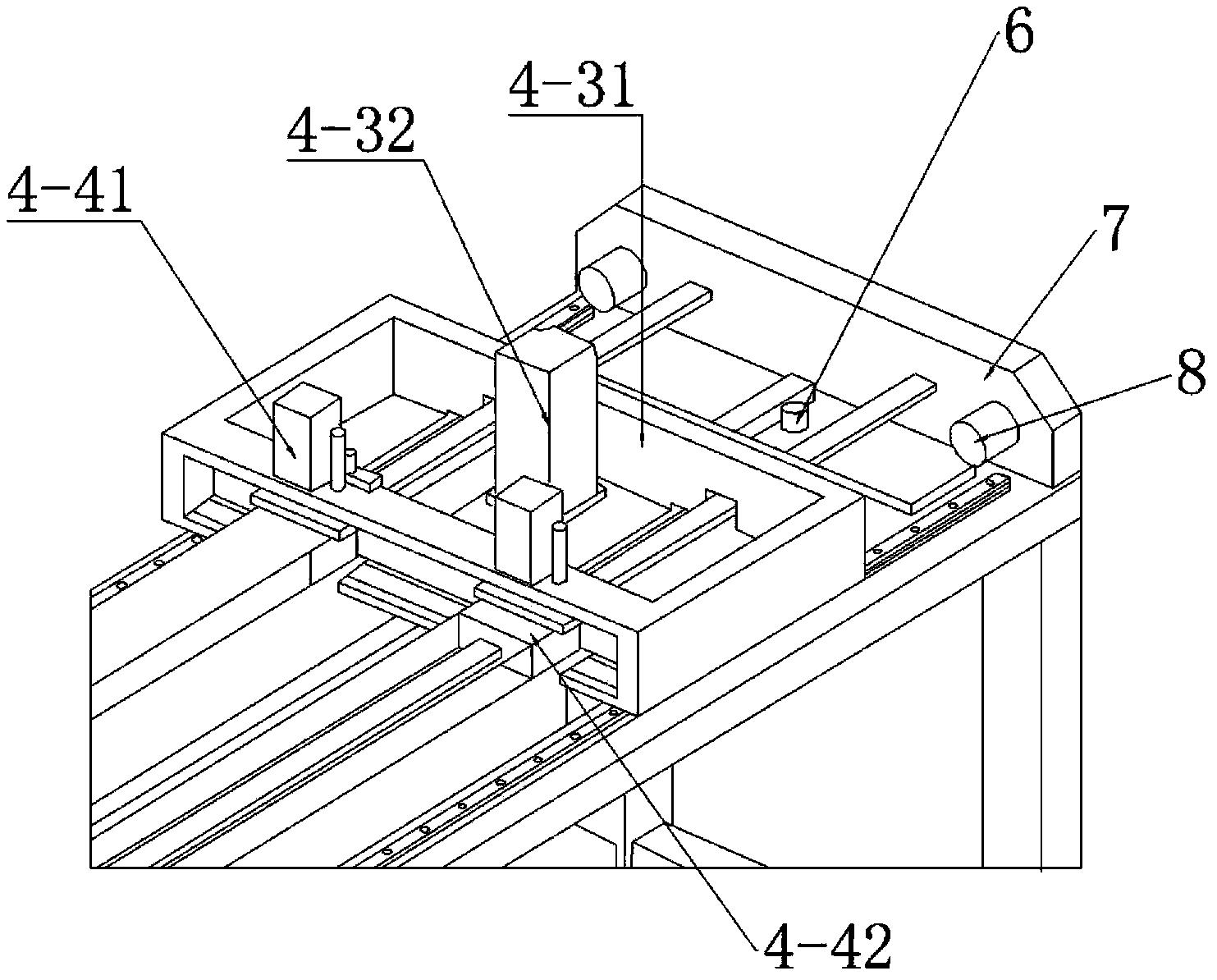

[0023] Such as Figure 1-Figure 4 As shown, an automatic feeding punching machine includes a punching mechanism 1, a control device 2, a feeding frame 3 and an automatic feeding mechanism 4 arranged on the feeding frame 3, and the automatic feeding mechanism 4 includes an automatic feeding mechanism installed on the feeding frame 3 The supporting roller 4-1 on the top, the linear guide rail 4-2, the driving mechanism 4-3 provided on the linear guide rail 4-2, the driving mechanism 4-3 is provided with a clamping mechanism 4-4, which is used to fix the profile and pass The control device drives the driving mechanism to send the profiles into the punching mechanism 1 for punching; the driving mechanism 4-3 includes a traction trolley 4-31 and a servo motor 4-32 that drives the traction trolley to move along the linear guide rail 4-2. The servo motor 4 -32 is connected with the control device 2, and the motion state of the traction trolley is controlled by the control device 2; t...

Embodiment 2

[0027] The difference between this embodiment and the above-mentioned embodiment is that the material clamping mechanism includes a material clamping seat and a clamping cylinder, the material clamping seat is composed of a bottom plate and left and right side plates, and the clamping cylinder is vertically arranged above the bottom plate, The left and right side plates can realize the positioning of the left and right sides of the profile, and the clamping cylinder is used to press the profile onto the clamping seat to realize the up and down positioning of the profile. There are at least two clamping seats and clamping cylinders, so that the automatic feeding mechanism can send two profiles to the punching mechanism at one time, and carry out the punching process on the two profiles at the same time to improve production efficiency. At least one of the left and right side panels is connected with a width adjusting mechanism for adjusting the distance between the two side pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com