Pulse power supply used in electric precipitation

A technology of pulse power supply and electrostatic precipitator, which is applied in the field of design of electrostatic precipitator equipment, can solve the problems affecting the performance of the precipitator, uneven charge distribution, back corona, etc., to prevent back corona phenomenon, simplify the circuit structure, increase the The effect of scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

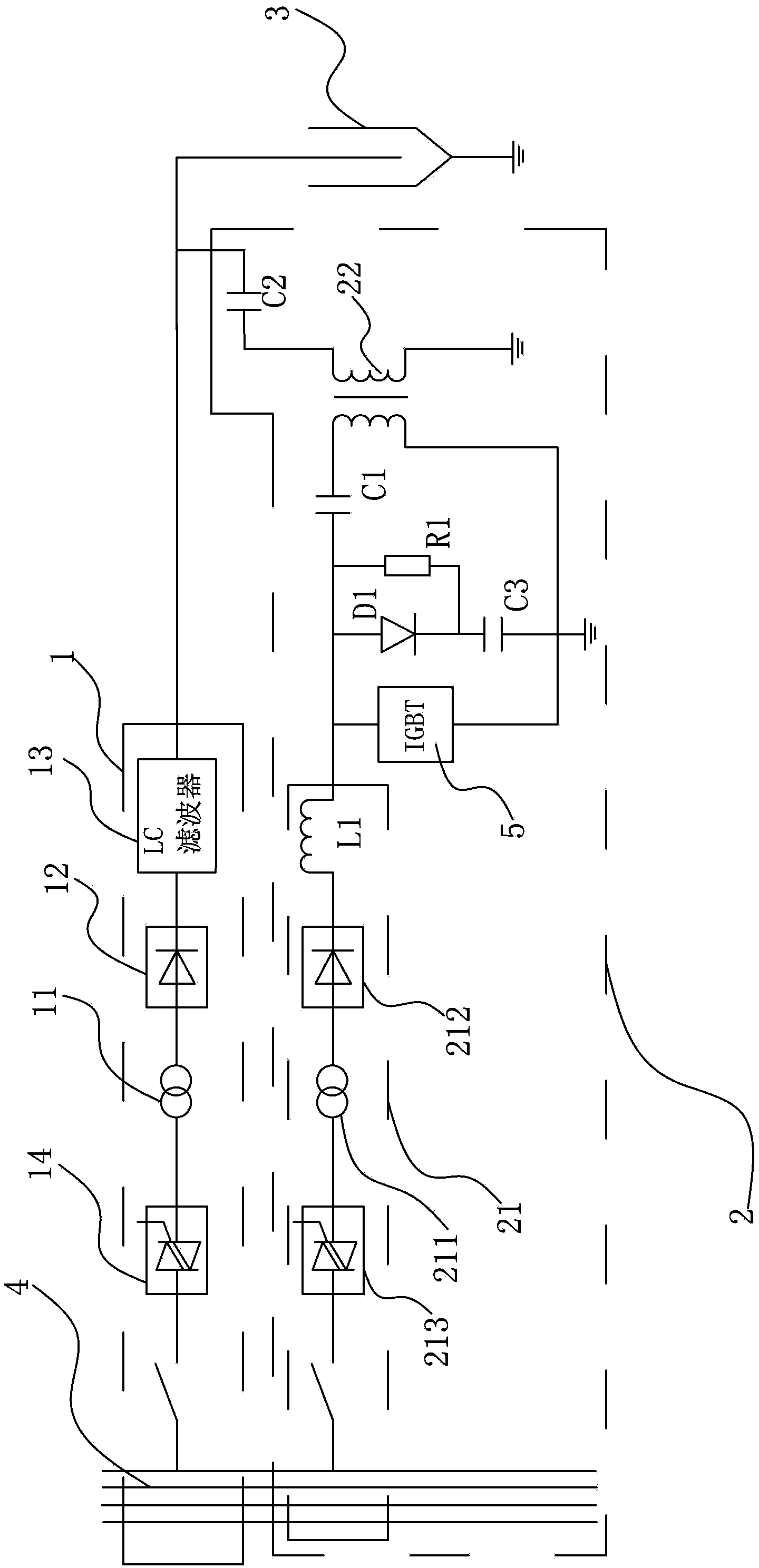

[0015] Such as figure 1 As shown, a pulse power supply for electric dust removal includes a DC high-voltage power supply circuit 1 and a pulse high-voltage power supply circuit 2. The DC high-voltage power supply circuit 1 is connected to the dust collector 3 and does not provide a basic voltage for the dust collector 3 to start the dust removal program. The power supply circuit 2 is coupled to the DC high-voltage power supply circuit 1, and the DC high-voltage power supply circuit 1 and the pulse high-voltage power supply circuit 2 share a low-voltage AC power supply 4. In actual use, the low-voltage AC power supply 4 is a low-voltage three-phase AC power supply. The pulse high-voltage power supply circuit includes an AC-DC conversion circuit 21 and a pulse transformer 22. The AC-DC conversion circuit 21 includes a low-voltage AC power supply 4 connected in series, a first step-up transformer 211, a first rectifier bridge 212 and a smoothing inductance L1. The step-up transfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com