Glass composition with low coefficient of thermal expansion, and glass fiber produced from same

A technology of glass composition and thermal expansion coefficient, which is applied in glass manufacturing equipment, manufacturing tools, transportation and packaging, and can solve problems such as low elastic modulus, difficult continuous processing, and low hollow wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

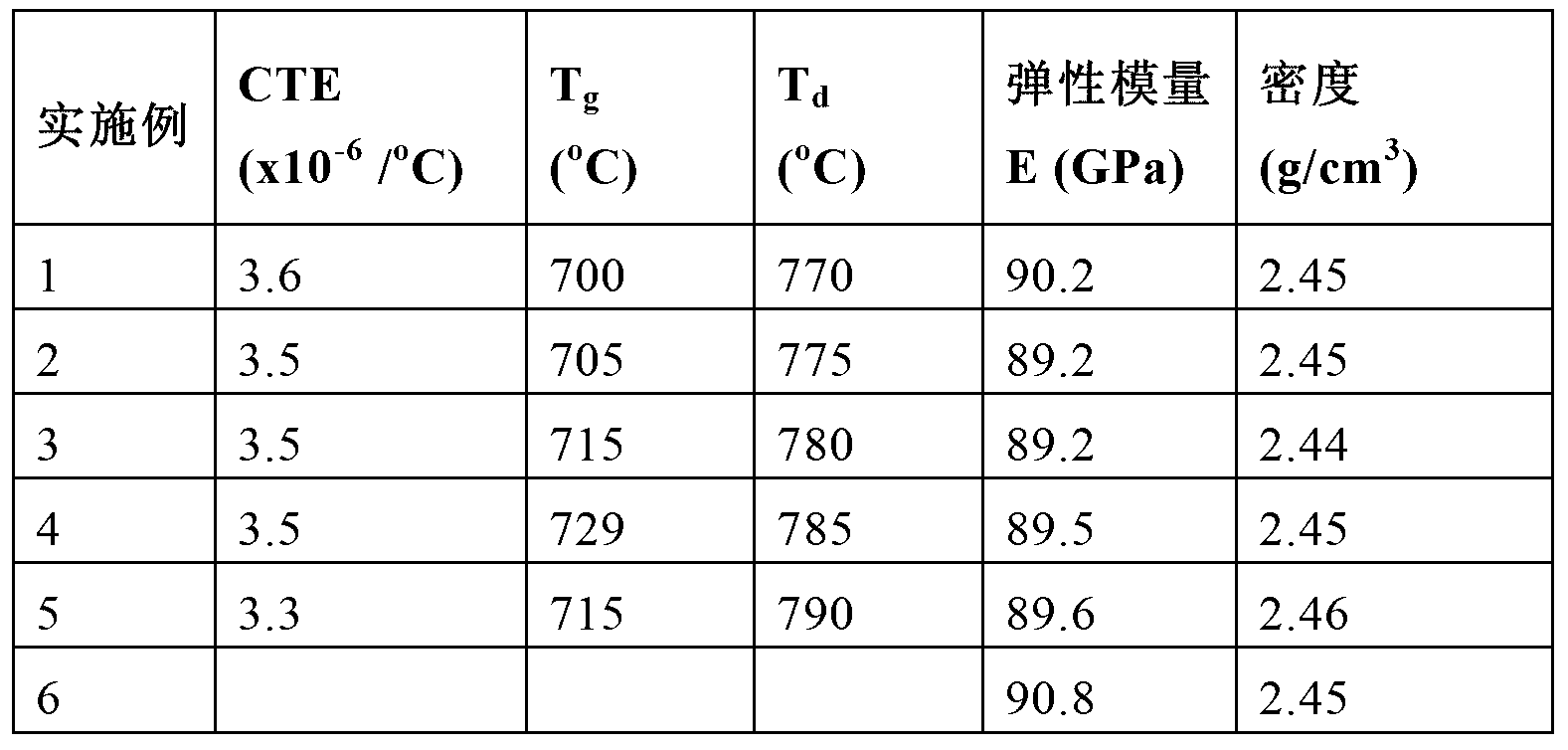

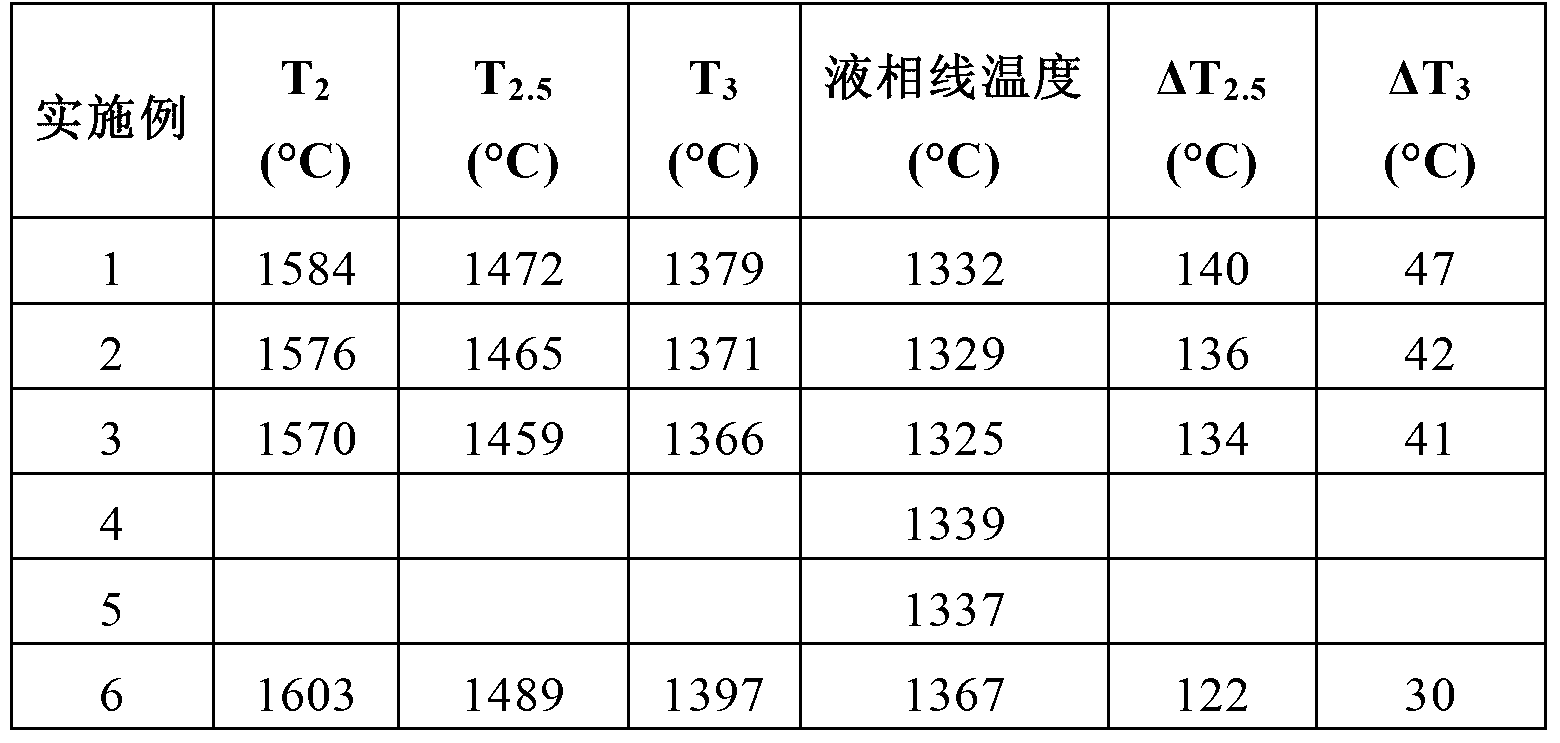

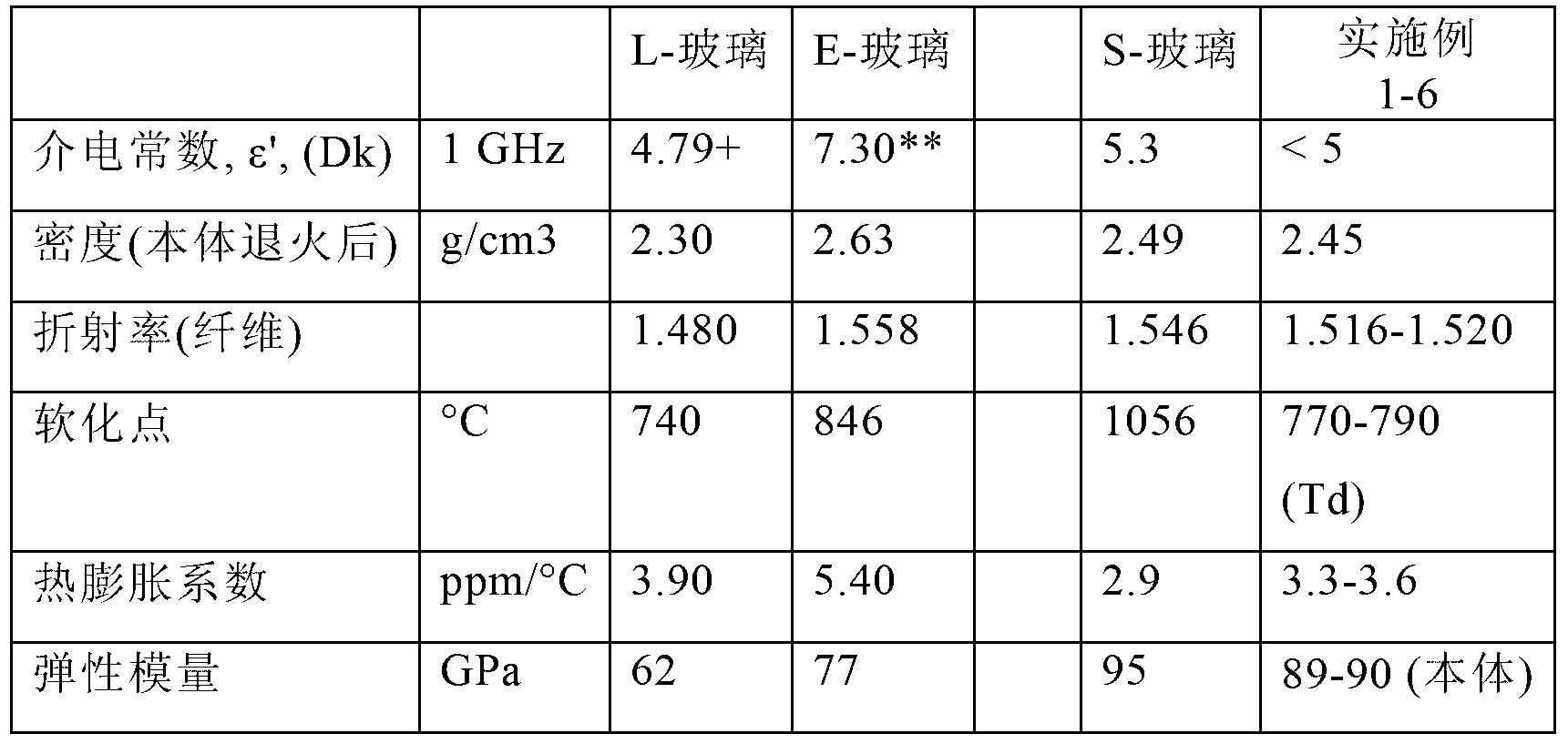

Examples

Embodiment Construction

[0015] Although the present disclosure has been described in conjunction with specific embodiments, it should be understood that various changes and modifications can be made by those skilled in the art without departing from the spirit and scope of the present invention. are defined by the appended claims and their equivalents.

[0016] Glass compositions according to embodiments disclosed and described herein are provided having from about 55% to about 65% by weight silica, from about 15% to about 30% by weight alumina, from about 5% to about 15% by weight % by weight magnesium oxide, about 3% to about 10% by weight boron oxide, about 0 to about 11% by weight calcium oxide, and about 0 to about 2% by weight alkali metal oxide, with a balance of less than about 1 % by weight of trace compounds.

[0017] Boron oxide generally functions as a flux in glass compositions. In appropriate amounts, boron oxide can lower the melting temperature without increasing the CTE of the glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com