Slip-casting preparation method of porous anode supporter of solid-oxide fuel cell

A solid oxide and fuel cell technology, applied to fuel cell components and other directions, can solve the problems of difficult dispersion, additive compounding, and preparation of dense electrolyte membranes, etc., and achieve moderate fluidity and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare a battery with 10% graphite mass content:

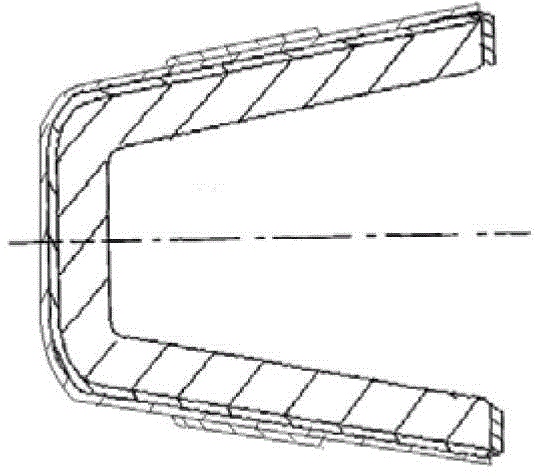

[0036] 1. Preparation of anode support by gypsum mold grouting

[0037] (1) Mix NiO and YSZ with a mass ratio of 1:1 to obtain anode powder, add 10% graphite, 0.6% calcium lignosulfonate, 0.6% chitosan, 300 % of dilute acetic acid with a mass concentration of 1%, and then ball milled for 2 hours to obtain a slurry with good fluidity after mixing evenly.

[0038] (2) Use a dropper to inject the above prepared slurry into a plaster mold, make the mold full of slurry, absorb the moisture of the slurry through the capillary action of the mold, pour out the remaining slurry after 5 minutes, and the body attached to the surface of the mold Release the mold after drying and shrinking to obtain the anode green body.

[0039] 2. Preparation of the functional layer on the outer surface of the anode green body:

[0040] Mix NiO and YSZ at a mass ratio of 1:1 to obtain a solid powder, by weight of the solid powder, add 2.8% tri...

Embodiment 2

[0046] Prepare a battery with 5% graphite mass content:

[0047] (1) Mix NiO and YSZ with a mass ratio of 1:1 to obtain anode powder, add 0.1% calcium lignosulfonate, 1% chitosan, and 300% mass concentration of 1% Dilute acetic acid, 5% graphite, and then ball mill for 2 hours to mix evenly to obtain a slurry with good fluidity.

[0048] (2) Use a dropper to inject the above-mentioned prepared slurry into a plaster mold, fill the mold with slurry, and absorb the moisture of the slurry through the capillary action of the mold. After 15 minutes, pour out the remaining slurry, and the blank attached to the surface of the mold After the body dries and shrinks, it is released from the mold to obtain an anode green body.

[0049] (3) Mix NiO and YSZ at a mass ratio of 1:1 to obtain a solid powder, and add 2% of triethanolamine, 2% of polyethylene glycol, 2% of dioctyl phthalate and 2% polyvinyl butyral dissolved in 200% absolute ethanol at 60° C., and then mechanically mixed unifo...

Embodiment 3

[0052] Prepare a battery with 15% graphite mass content:

[0053] (1) Mix NiO and YSZ with a mass ratio of 1:1 to obtain an anode powder, add 1% calcium lignosulfonate, 0.1% chitosan, and 300% of a mass concentration of 1% Dilute acetic acid, 15% graphite, and then ball mill for 2 hours to mix evenly to obtain a slurry with good fluidity.

[0054] (2) Use a dropper to inject the above-mentioned prepared slurry into a plaster mold, so that the mold is filled with the slurry, and absorb the moisture of the slurry through the capillary action of the mold. After 2 minutes, pour out the remaining slurry, and the blank attached to the surface of the mold After the body dries and shrinks, it is released from the mold to obtain an anode green body.

[0055] (3) Mix NiO and YSZ at a mass ratio of 1:1 to obtain a solid powder, and add 4% of triethanolamine, 4% of polyethylene glycol, 4% of dioctyl phthalate and 6% polyvinyl butyral dissolved in 300% absolute ethanol at 60° C., and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com