Defect casual inspection method capable of dynamically adjusting according to technology wafer number load

A dynamic adjustment and defect detection technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc., can solve unfavorable production cycle and cost control, lack of wafers to be processed, and increase in the number of wafers and other issues, to achieve the effect of shortening the production cycle, increasing the speed, and avoiding the slowdown of the production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

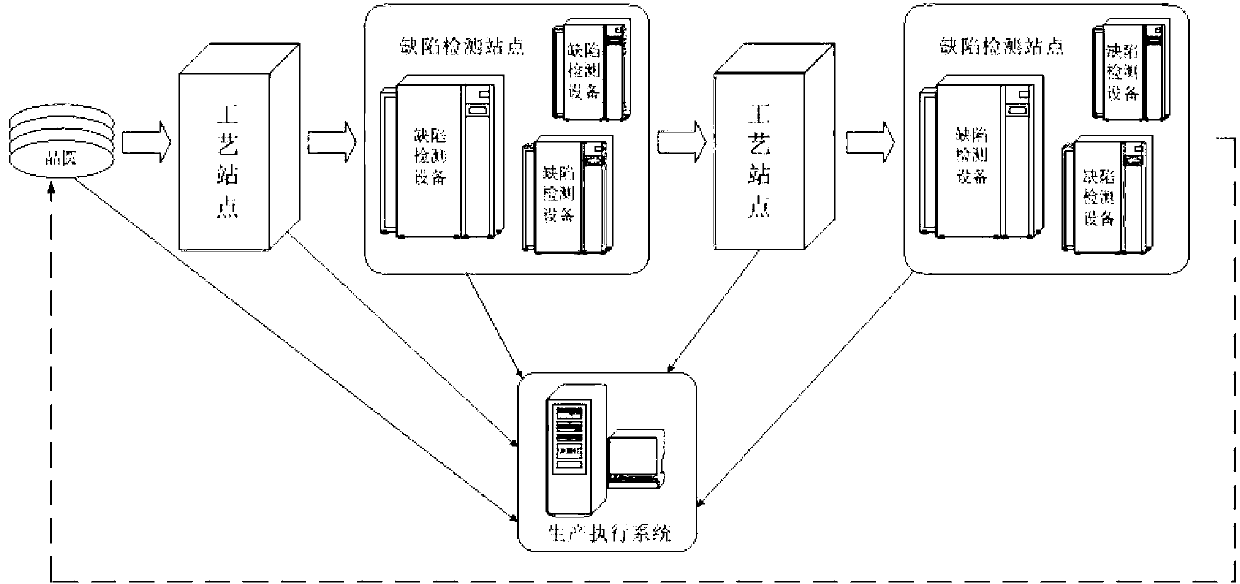

[0028] The first embodiment of the present invention relates to a defect sampling inspection method that can be dynamically adjusted according to the load of the number of process wafers, which is applied to the production execution system and adopts the following steps:

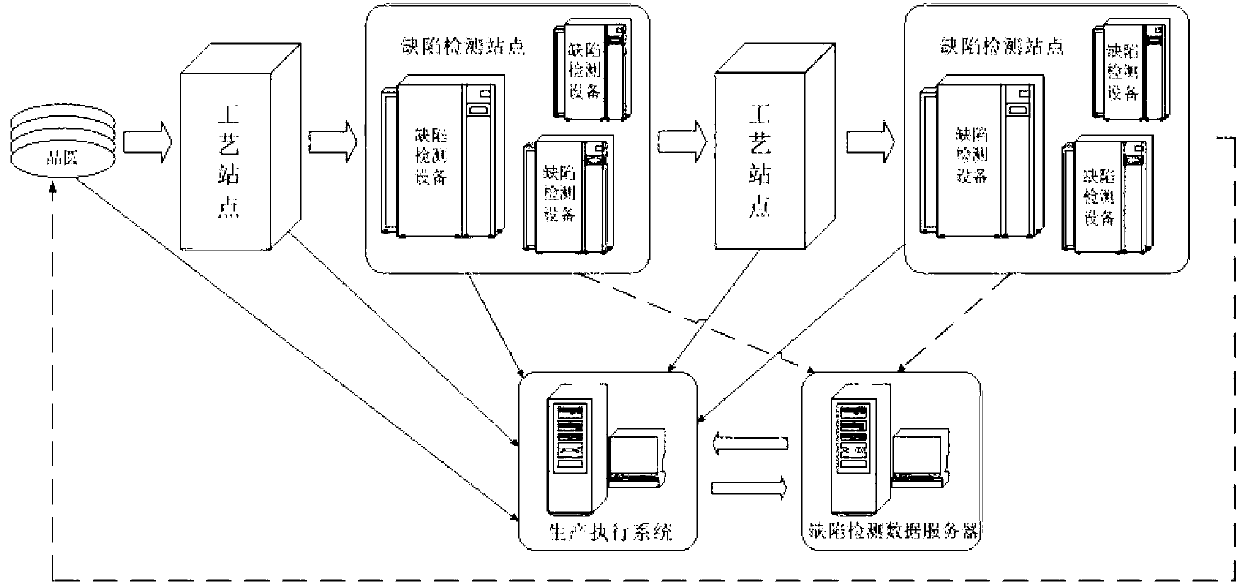

[0029] Step S1, preset in the production execution system as image 3 Defect detection data server shown.

[0030] Step S2, inputting and saving the benchmark sampling frequency of the defect detection site during normal production and the operating rates of different defect detection programs into the defect detection data server.

[0031] Step S3, the defect detection data server calculates the real-time production capacity of the defect detection site according to the real-time status of each defect detection device in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com