LCD panel, drive method and LCD device

A technology of liquid crystal panel and driving method, applied in static indicators, nonlinear optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

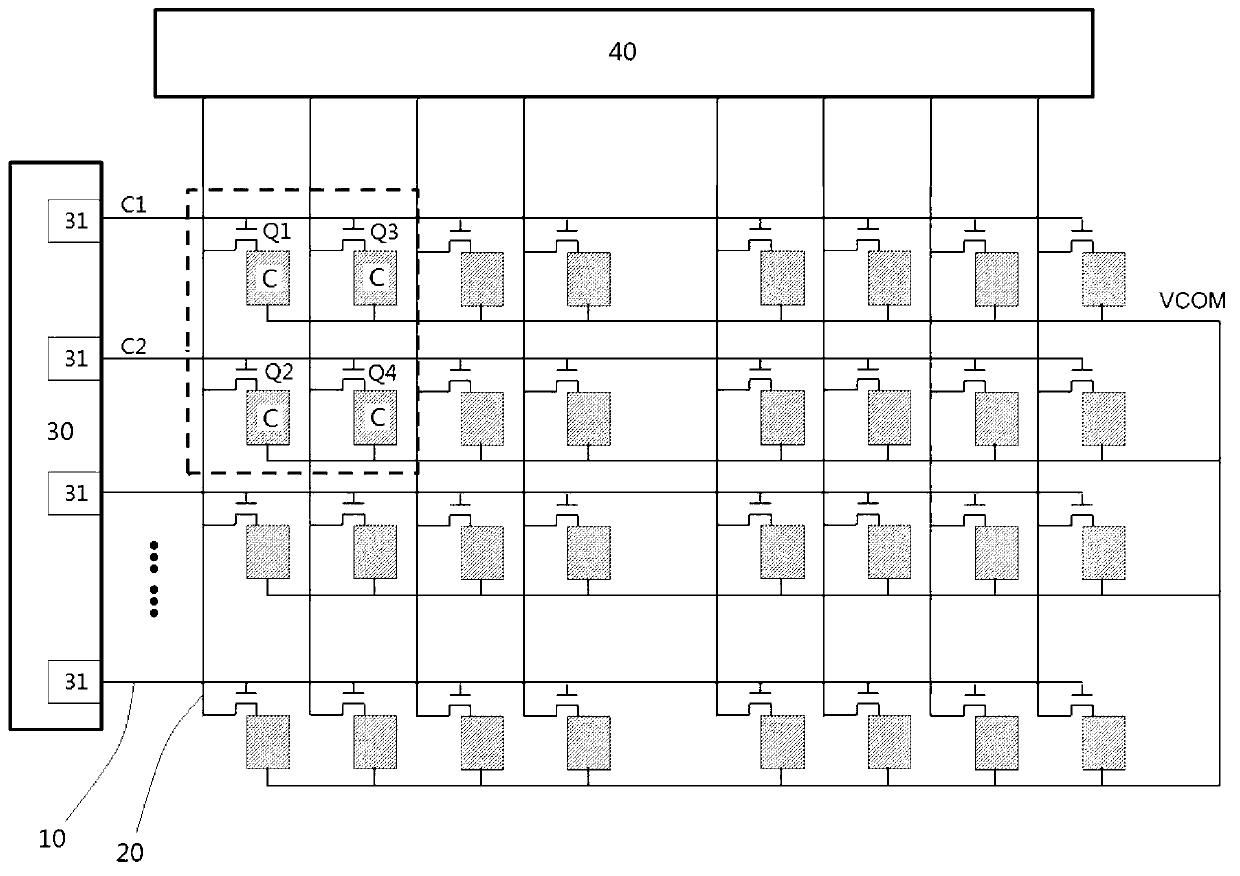

[0040] Such as figure 2 As shown, the liquid crystal panel includes a plurality of thin film transistors, crisscrossed scan lines 10 and data lines 20, a scan driving chip 30 driving the scan lines 10, and a data driving chip 40 driving the data lines 20; the gate of each row of TFTs is connected to one In the scan line 10, the source of each TFT is connected to a data line 20, and the drain of each TFT is connected to a pixel electrode. The scan driving chip 30 includes a compensation driving unit 31 coupled to the scan line 10.

[0041] The compensation driving unit 31 drives the thin film transistor corresponding to the scan line C2 of the next row to be turned on when or after the scan driving chip 30 drives the thin film transistor corresponding to the current scan line C1 to conduct, and the thin film transistor corresponding to the current scan line C1 receives The thin film transistor corresponding to the next row of scan line C2 is turned off when the data signal of the ...

Embodiment 2

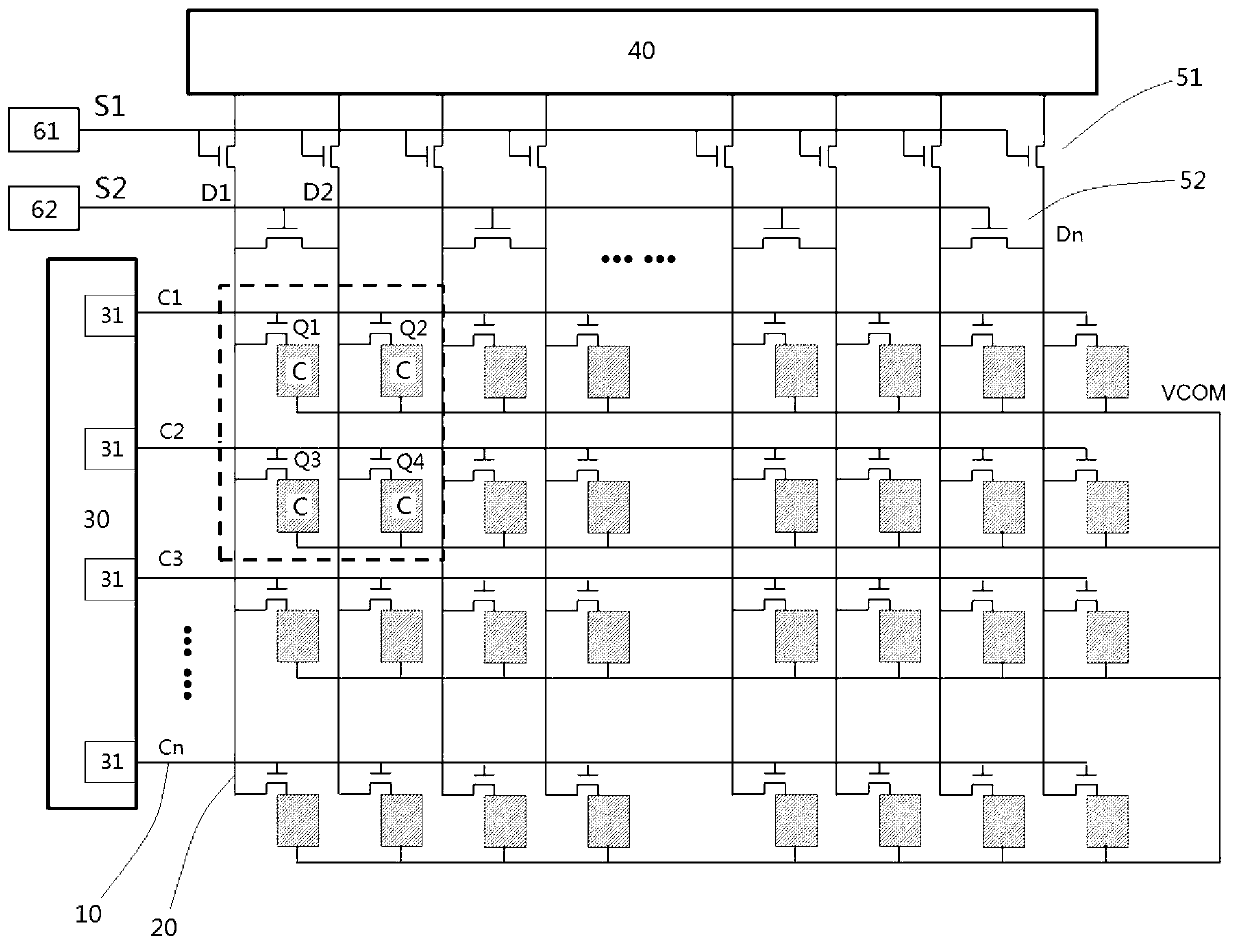

[0047] Such as image 3 As shown, this embodiment discloses a method for driving a liquid crystal panel. The liquid crystal panel includes a plurality of thin film transistors, crisscrossed scan lines and data lines, a scan driving chip for driving the scan lines, and a data driving chip for driving the data lines; The gate of each row of TFTs is connected to a scan line, the source of each column of TFTs is connected to a data line, and the drain of each TFT is connected to a pixel electrode; the driving method includes:

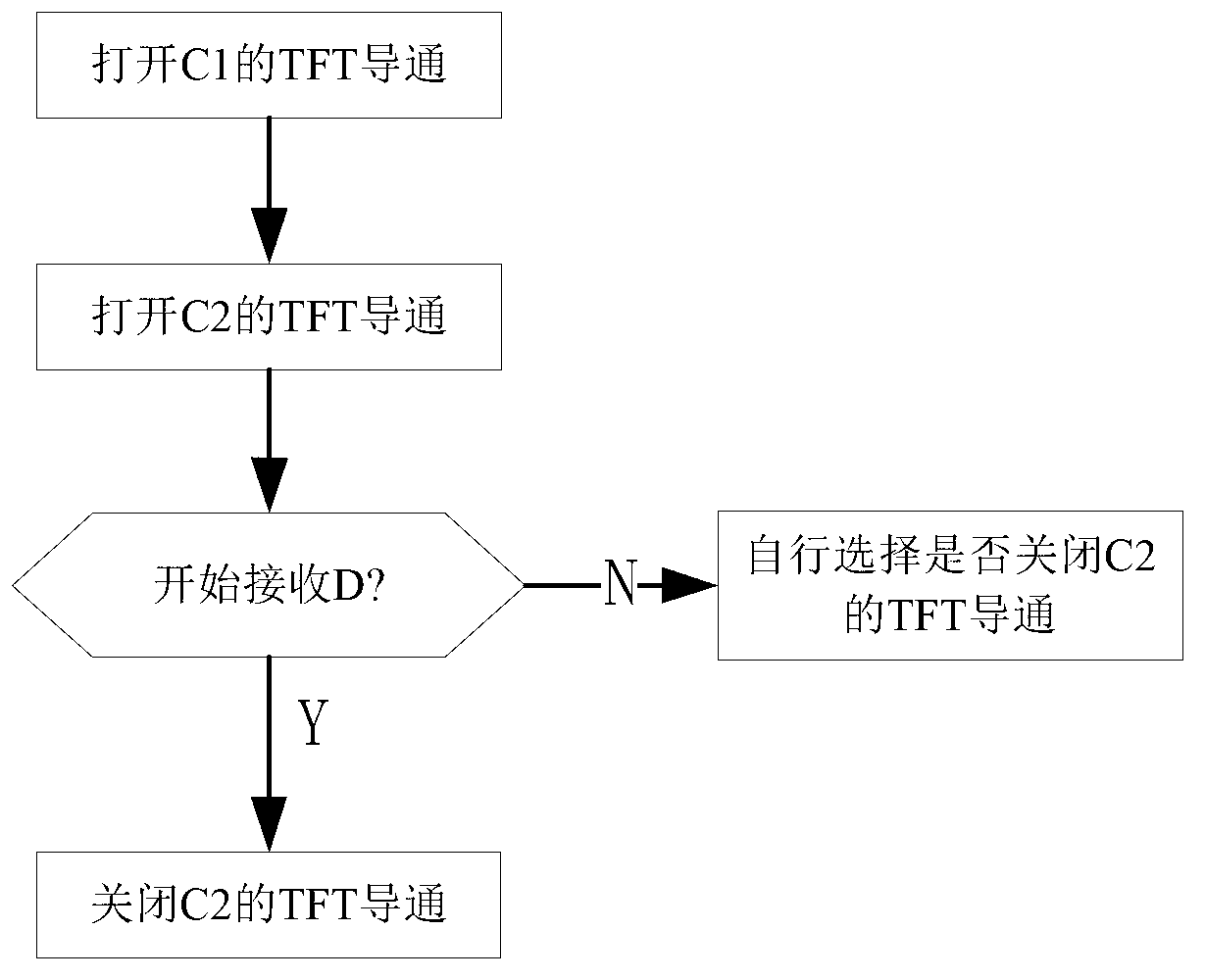

[0048] A. The scan driving chip drives the thin film transistor corresponding to the current scan line C1 to turn on;

[0049] B. The scan driving chip drives the thin film transistor corresponding to the next row of scan line C2 to turn on;

[0050] C. Determine whether the thin film transistor corresponding to the current scan line starts to receive the data driving signal of the data drive chip D, and drive the next row of scan line when or before the thin film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com