Concrete capable of resisting concentrated seawater and desulfurization flue gas corrosion

A technology for concentrating seawater and concrete, applied in the field of concrete, can solve the problems of corrosion of reinforced concrete and affect the durability of concrete, and achieve the effects of high water reduction rate, easy construction and operation, and improved labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Concrete resistant to concentrated seawater and desulfurized flue gas corrosion, including gravel, sand, gelling materials, admixtures and water.

[0027] The crushed stone used in the preparation of concrete is continuously graded crushed stone with a particle size of 5 mm to 25 mm, and the bulk density of the crushed stone is > 1450 kg / m 3 , porosity ≤ 42%, water absorption ≤ 2%, crushing index ≤ 12%, mud content ≤ 1.5%, chloride ion content ≤ 0.01%.

[0028] The sand used to prepare concrete is river sand, the fineness modulus of the sand is 2.4-3.0, the mud content is ≤2%, the chloride ion content is ≤0.01%, and the accumulated sieve residue of the 4.75mm sieve is controlled to be 0-5%. The cumulative sieve allowance of 0.6mm sieve is 40%~70%, and the cumulative sieve allowance of 0.15mm sieve is more than 95%.

[0029] The cementitious material is composed of cement, mineral powder and fly ash. The cement used is Portland cement with a strength grade of not less ...

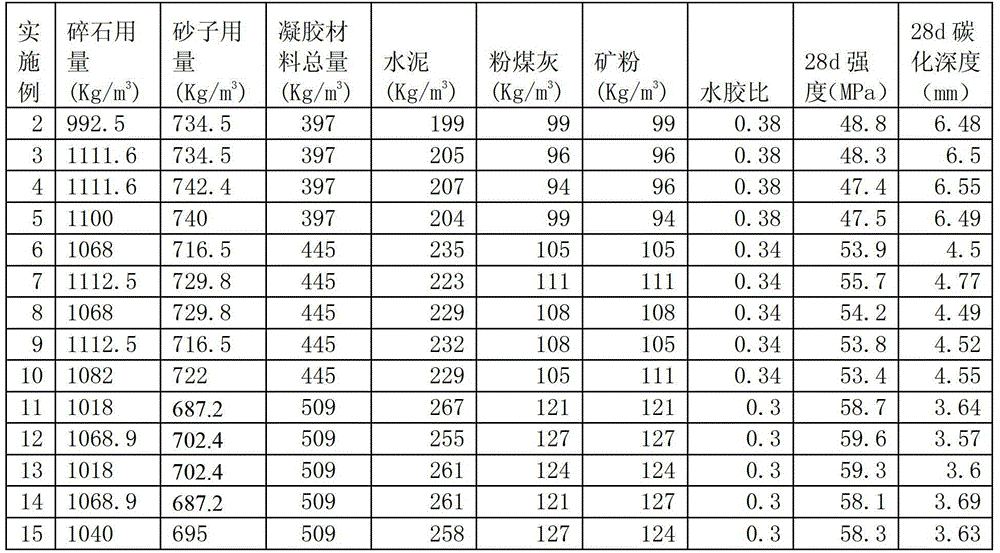

Embodiment 2~15

[0033] The formula of embodiment 2~15 and the concrete performance that make are as shown in the table below:

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com