Flexible pipe cleaning device of spray dryer

A spray dryer, cleaning device technology, applied in the direction of liquid cleaning method, cleaning method and utensils, chemical instruments and methods, etc., can solve equipment manufacturing cost and maintenance cost high, windproof, stability increase construction cost, construction Cost increase and other issues, to achieve the effect of ensuring smooth liquid supply, improving equipment reliability and safety, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

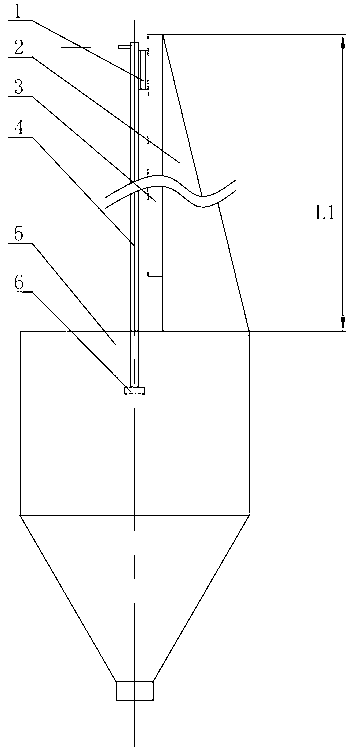

[0023] Such as figure 2 As shown, the hose cleaning device of the present invention is arranged on the top of the closed circulation spray drying tower 5, and the top of the frame 8 is provided with two tangential master-slave rollers, and the driving roller 12 is driven by the transmission chain 10 The motor 9 drives and rotates, and the driven roller 11 rotates; the roller surfaces of the driving roller 12 and the driven roller 11 are provided with grooves corresponding to the outer diameter of the hose 15, and the rubber hose 15 is clamped between the driving roller 12 and the Between the driven rollers 11, and ensure that the lifting centerline of the hose 15 is consistent with the centerline of the tower body, the central axis of the driven roller 11 is provided with a fine-tuning mechanism, which can adjust the clamping force, and the guide sleeve 7 is arranged on the lower side of the master and slave rollers . The end of the hose 15 is connected with a cleaning head ...

Embodiment 2

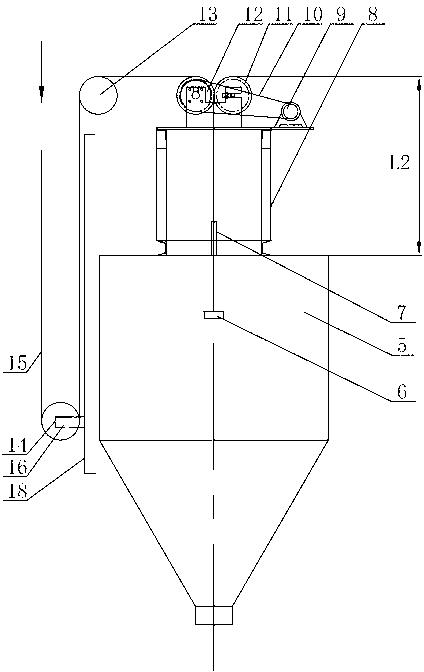

[0026] The structure of this embodiment is basically the same as that of Embodiment 1, but the hose 15 is not driven by the master-slave roller, but driven by the movable pulley 14 . Such as image 3 As shown, the sliding block 16 fixed by the central axis of the movable pulley 14 is driven by the motor 17, and moves up and down along the vertical rail 18; this structure does not need to set the master-slave roller, but only needs to set the fixed pulley and 19 pairs of hoses on the top of the tower. 15 for reversing, thereby simplifying the tower top structure. But because one stroke of the movable pulley 14 will result in twice the stroke of the cleaning head 6, the error for the movement will also be multiplied, so the movable pulley 14 needs to achieve more precise stroke control.

Embodiment 3

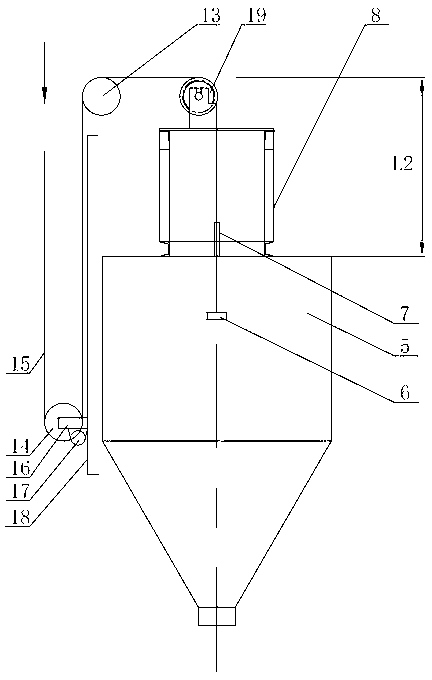

[0028] Such as Figure 4 As shown, the hoisting mechanism 20 is directly arranged on the top of the drying tower 5 in this embodiment, instead of the fixed pulley mechanism in the first embodiment. The outer circumference of the reel of the hoisting mechanism 20 is provided with a spiral groove, and the hose 15 is wound in the groove; the central axis of the hoisting mechanism 20 is a hollow shaft structure, one side of the shaft end communicates with the external cleaning agent input port, and the other side shaft end passes through The swivel joint 21 communicates with the hose 15; the hoisting mechanism 20 is driven by the motor 9 during operation, and the lifting of the cleaning head 6 is realized through the rotation of the reel. Compared with the structure of Embodiment 1, the structure of this embodiment can simplify the structure of the fixed pulley, but the hose 15 is easy to accumulate and wind on the reel, which affects the stability of the cleaning liquid delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com