Nano adsorbent for removing arsenic, stibium and fluorin in wastewater as well as preparation method and regeneration method of nano adsorbent

A nano-adsorption, adsorbent technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve problems such as failure to meet environmental protection requirements, and achieve good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

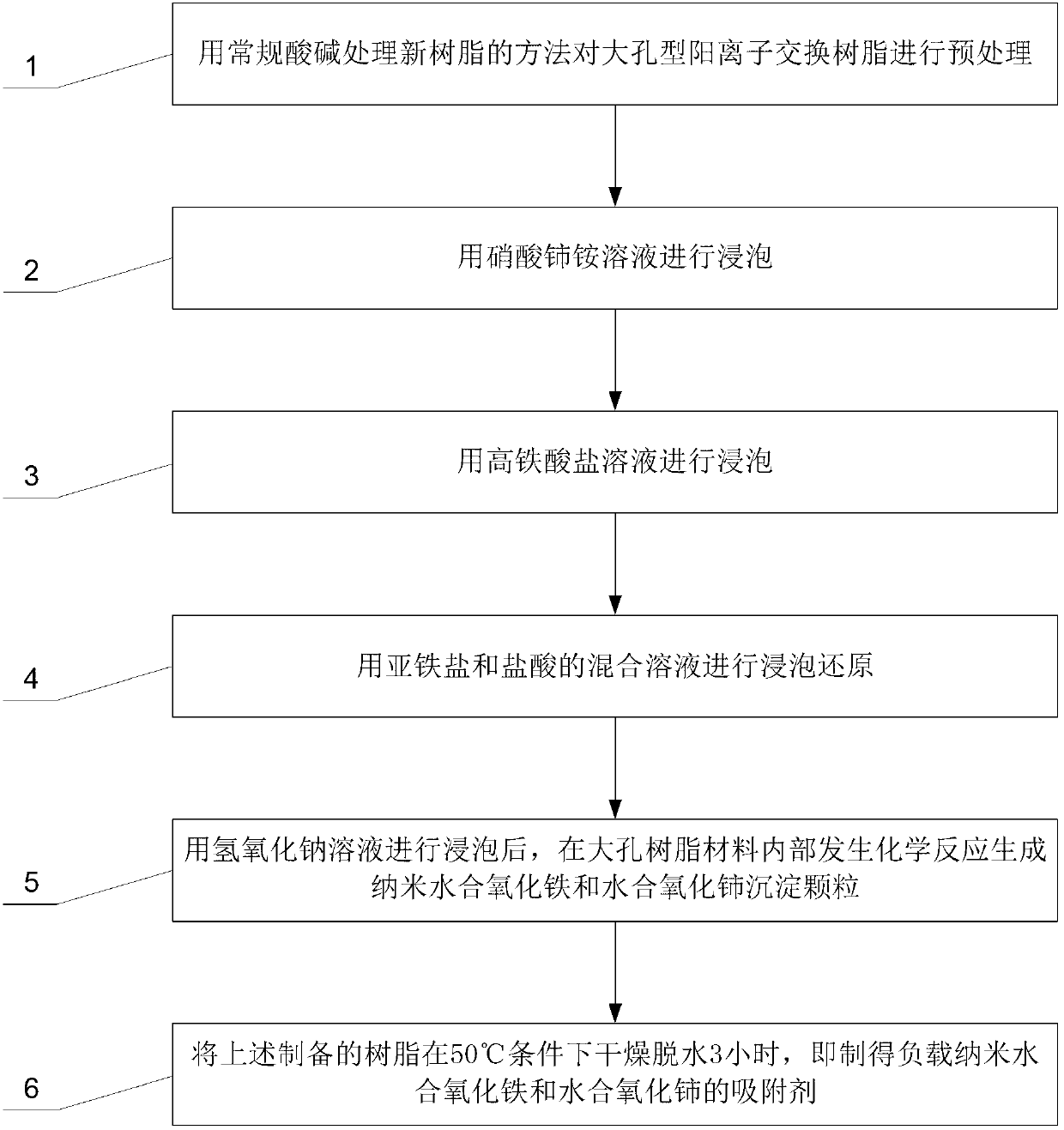

[0016] The embodiment of the present invention provides a method for preparing a nano-adsorbent for removing arsenic, antimony, and fluorine in wastewater, such as figure 1 shown, including the following steps:

[0017] Step 1. Pretreat the macroporous cation exchange resin by conventional acid-base treatment of new resin.

[0018] Specifically, select a macroporous cation exchange resin, treat it with a conventional acid-base treatment method for new resin, and then wash it to neutral with deionized water.

[0019] Step 2, soaking with cerium ammonium nitrate solution.

[0020] Specifically, prepare a cerium ammonium nitrate solution with a concentration of 0.3-0.6mol / L, the volume of the cerium ammonium nitrate solution is 3 times the volume of the pretreated resin, soak the resin with the prepared cerium ammonium nitrate solution 3-6 hours, with the electrostatic adsorption of ion exchange resin to adsorb cerium nitrate ion into the resin, after the time is up, take out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com