Cleaning method and cleaning device

A cleaning device and autoclave technology, applied to cleaning methods and appliances, cleaning devices for processing textile materials, chemical instruments and methods, etc., can solve problems such as low critical temperature and safety, achieve shedding suppression, improve cleaning efficiency, and economically excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

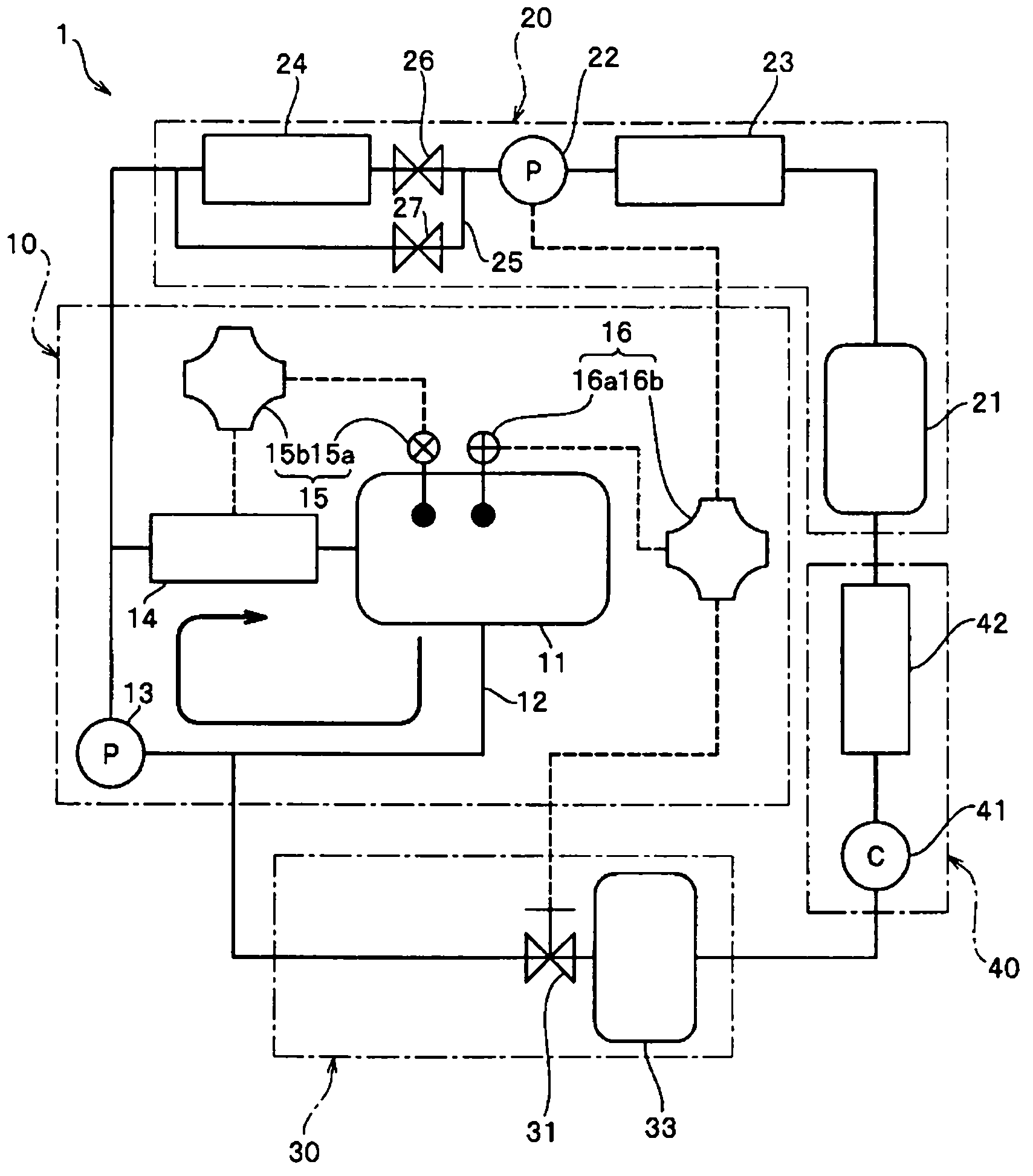

[0140] Prepare a tape-shaped fiber product made of polyester fiber, with respect to the fiber product, use figure 1 The cleaning device 1 is shown for dyeing.

[0141] In the dyeing process, first, a fiber product is wound in 11 layers on one bobbin, and the bobbin is accommodated in the autoclave 11 . In addition, a red dye (C.I. Disperse Red 22) is accommodated in the autoclave 11 together with fiber products. Next, the supply pump 22 is driven to supply supercritical carbon dioxide from the storage tank 21 to the circulation path 12 via the supply pump 22 and the preheating unit 24 . Simultaneously, the circulation pump 13 is also driven to circulate the supercritical carbon dioxide in the circulation path 12 and the autoclave 11 .

[0142] And while circulating supercritical carbon dioxide, the temperature in the autoclave 11 was raised to 125° C. by the temperature control unit 15, and the pressure in the autoclave 11 was increased to 25 MPa by the pressure control uni...

Embodiment 2

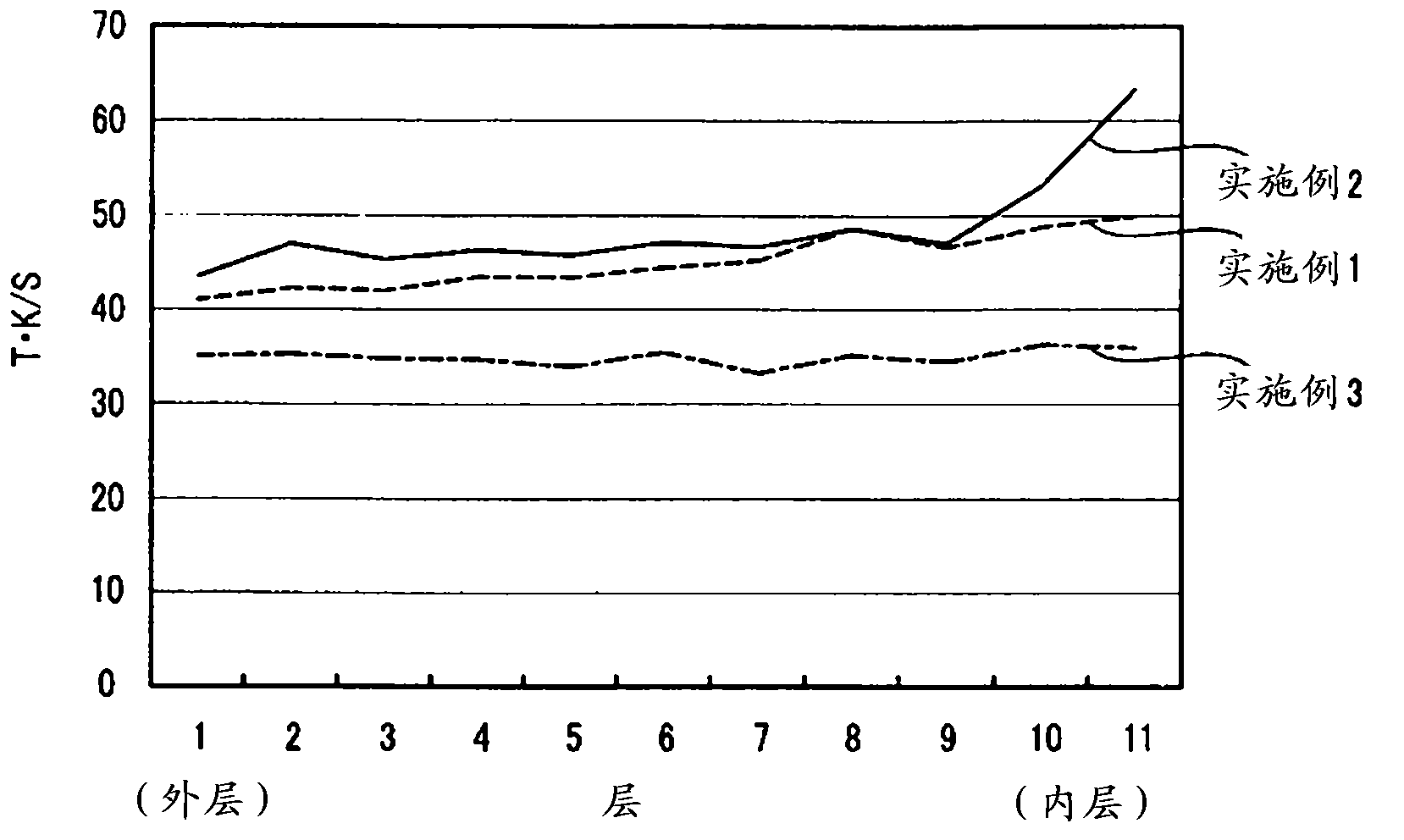

[0147] In Example 2, in the washing process, except that the temperature drop rate in the autoclave 11 was controlled at 10.83°C / min, the dyeing and washing of the fiber product were carried out in the same manner as in the above-mentioned Example 1. deal with. After that, the total K / S of the obtained fiber product and the color difference ΔE of each layer were calculated. CMC(2:1) .

Embodiment 3

[0149] In Example 3, the dyeing and washing of the fiber product were carried out in the same manner as in Example 1 above, except that the temperature in the autoclave 11 was lowered at a rate of 1.10°C / min during the washing process. deal with. After that, the total K / S of the obtained fiber product and the color difference ΔE of each layer were calculated. CMC(2:1) .

[0150] Here, for the above-mentioned fiber products of Examples 1 to 3, the results of calculating the total K / S are shown in image 3 , In addition, the color difference ΔE of each layer will be obtained CMC(2:1) The result expressed in Figure 4 . In addition, in image 3 and Figure 4 In the graph, the horizontal axis represents each layer of the fiber product when the fiber product is wound on the bobbin. On the horizontal axis, the outermost layer of the wound fiber product is the first layer, and the innermost ( center side) is the 11th floor.

[0151] After cleaning the fiber products of Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com