A curved-surface-BIPV-photovoltaic-assembly and a preparation technology thereof

A photovoltaic module and curved surface technology, applied in the field of curved BIPV photovoltaic module and its preparation process, can solve the problems of single form, photovoltaic application can not better cut into the architectural design concept, etc., to achieve diversified forms, easy production, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

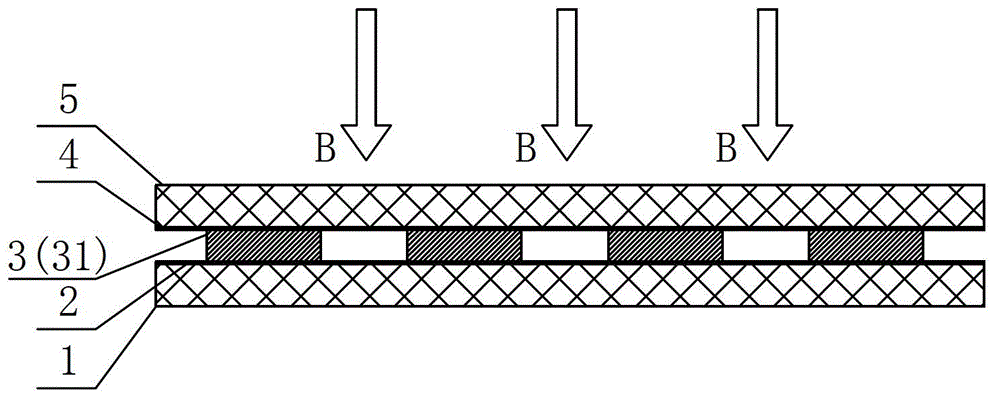

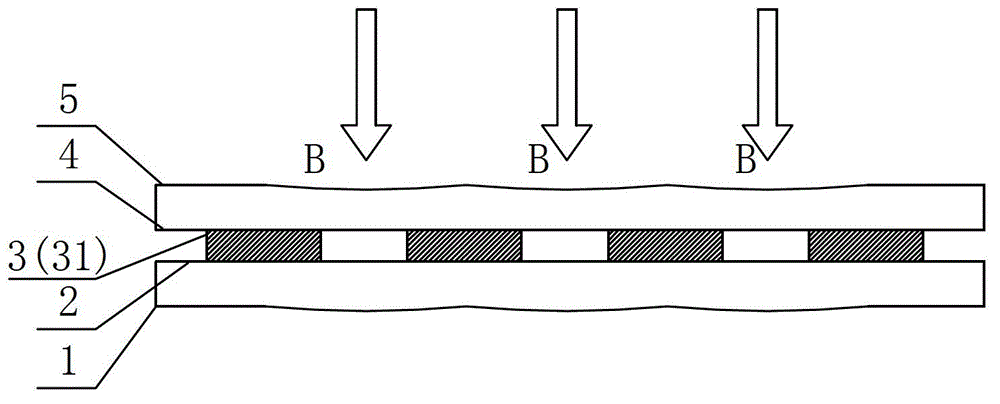

[0027] Such as figure 1 As shown, a curved surface BIPV photovoltaic module according to the present invention includes a glass front cover plate 1, an adhesive layer 2, a solar cell 3, another adhesive layer 4 and a glass back plate 5 laminated in sequence. The solar cell 3 is formed by crystalline silicon solar cells or flexible thin film cells 31 arranged in series and welded in series at certain intervals, and consists of a glass front cover layer 1, an adhesive layer 2, a solar cell 3, and an adhesive layer. 4 and the glass back plate layer 5 are laminated to form a bending area B on the photovoltaic module, and the bending area B is placed between two rows of the solar cell array. In the present invention, the glass front cover plate 1 and the glass back plate 5 are all made of ultra-clear float glass with high transmittance, and the adhesive layers 2 and 4 are PVB film layers, or other polymers It is made of adhesive film layer, and the distance between the solar cells...

Embodiment 2

[0038] This embodiment is basically the same as the first embodiment above, except that the heating method of the infrared lamp in the above step (5) is replaced by the heating method of carbon dioxide laser.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com