Method for measuring the removal amount of the bottom metal layer of the contact hole

A bottom metal layer and contact hole technology, which is applied in the field of semiconductors, can solve the problems of hidden product quality, large distortion and error of results, and large distortion and error, and achieve the effects of saving manpower, stabilizing resistance value and electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

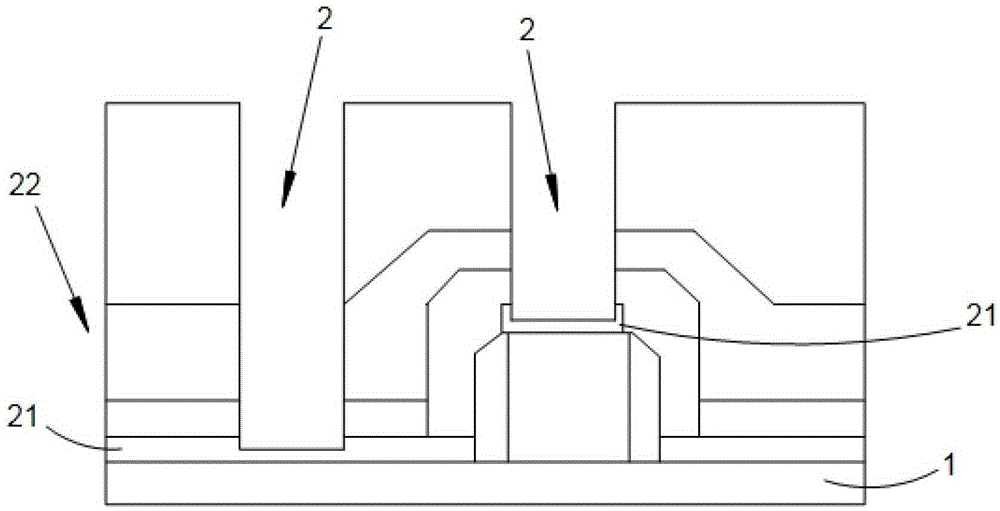

[0021] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

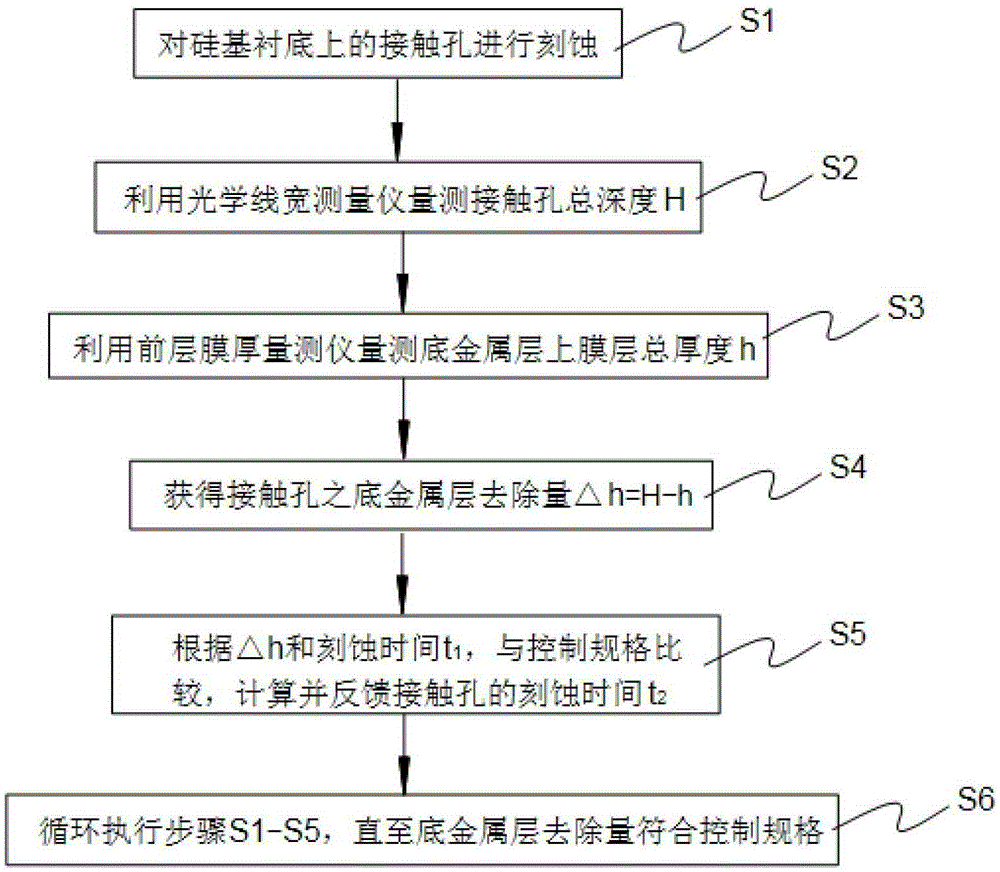

[0022] see figure 1 , figure 1 Shown is a flow chart of the method for measuring the removal amount of the bottom metal layer of the contact hole according to the present invention. The method for measuring the removal amount of the bottom metal layer of the contact hole includes:

[0023] Executing step S1: etching the contact hole provided on the silicon-based substrate;

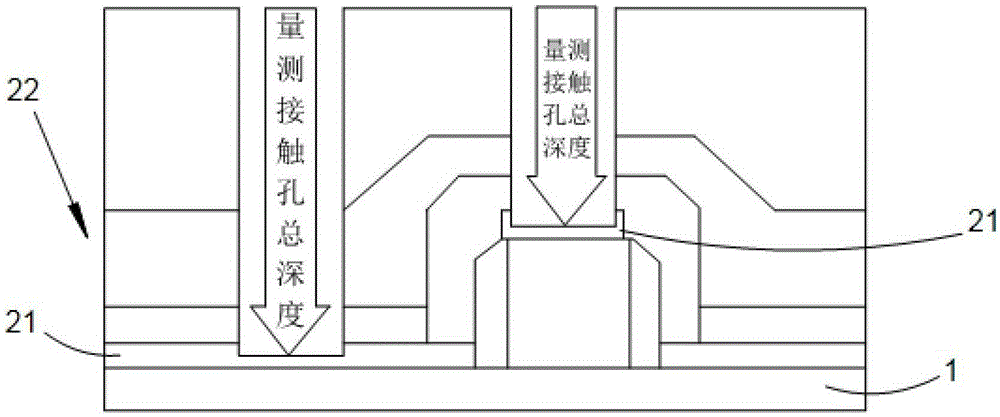

[0024] Executing step S2: measuring the total depth H of the contact hole by using an optical line width measuring instrument;

[0025] Executing step S3: measuring the total thickness h of the film layer on the bottom metal layer of the contact hole by using the front-layer film thickness measuring instrument;

[0026] Execute step S4: obtain the removal amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com