Equipment and method used for measuring friction coefficient between plastic and metal mold

A technology for measuring devices and metal molds, applied in measuring devices, adopting mechanical devices, analyzing materials, etc., can solve problems such as long time for setting temperature, slow temperature rise of incubator, low calculation accuracy, etc., and achieve the measurement process and method Convenience, ease of operation, and the effect of expanding the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

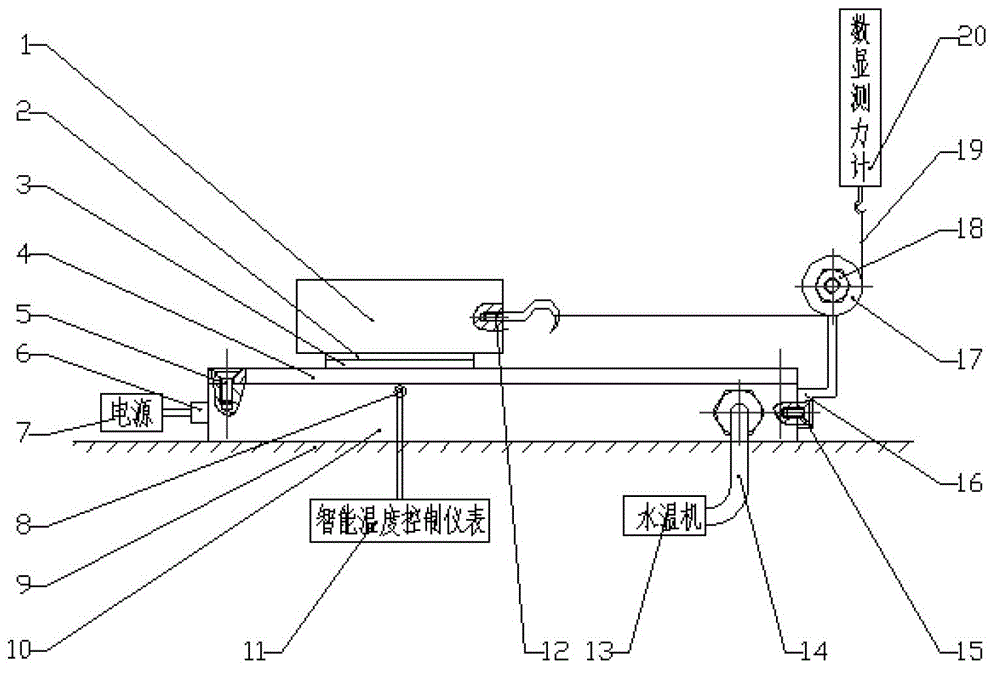

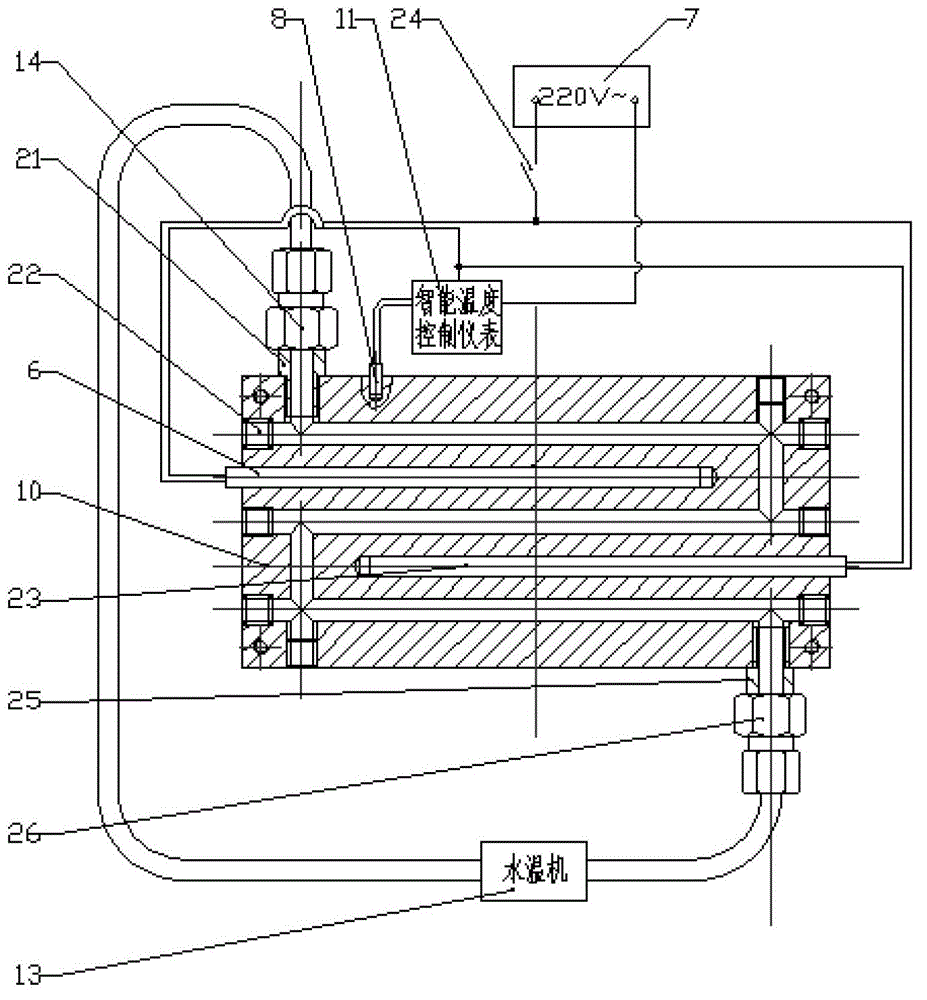

Method used

Image

Examples

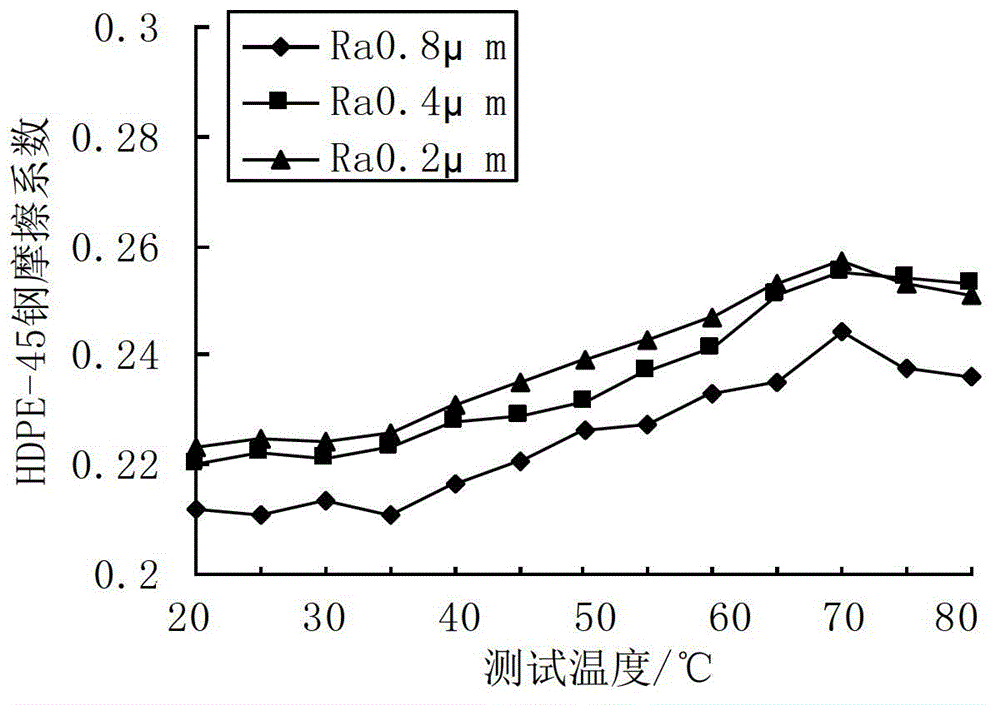

Embodiment 1

[0022] Example 1 Using a high-density polyethylene (HDPE) material test piece, when the demoulding temperature is 20°C to 80°C, the surface roughness of the 45 steel core is measured at Ra0.8μm, Ra0.4μm and Ra0.2μm friction coefficient, the measured result curve is as follows image 3 shown. It can be seen from the curve in the figure that the friction coefficient values at different measurement temperatures are all greater than the friction coefficient value of HDPE material and steel given in the relevant manual 0.109. It shows that the friction coefficient value between the plastic product and the metal mold at the demoulding temperature measured by the method of the present invention is more in line with the state during actual molding processing. The specific implementation method is that the 45 steel metal plate 4 with a surface roughness polished to Ra0.8 μm is fixed on the measuring table 10 through the countersunk screw 5, and then the test piece 3 made of HDPE mat...

Embodiment 2

[0023] Example 2 Using high-density polyethylene (PP) material specimens, when the demoulding temperature is 20°C to 80°C, the surface roughness of the 45 steel core is measured at Ra0.8μm, Ra0.4μm and Ra0.2μm friction coefficient, the measured result curve is as follows image 3 shown. It can be seen from the curve in the figure that the friction coefficient value varies greatly under different measurement temperatures; while the friction coefficient value between PP material and steel given in the relevant manual is 0.316. It can be seen that the friction coefficient value between the plastic product and the metal mold at the demoulding temperature measured by the method of the present invention is more in line with the actual situation during injection molding processing. The specific implementation method is that the 45 steel metal plate 4 with a surface roughness polished to Ra0.8 μm is fixed on the measuring table 10 through the countersunk screw 5, and then the test pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com