Thermoelectric-coupling type comprehensive energy-utilizing system based on air-cooling device and working method

A technology of thermoelectric coupling and air-cooling device, which is applied in the direction of steam engine device, preheating, steam application, etc., to achieve the effect of reduced engineering cost, good economy, and improvement of low-temperature corrosion problems in winter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

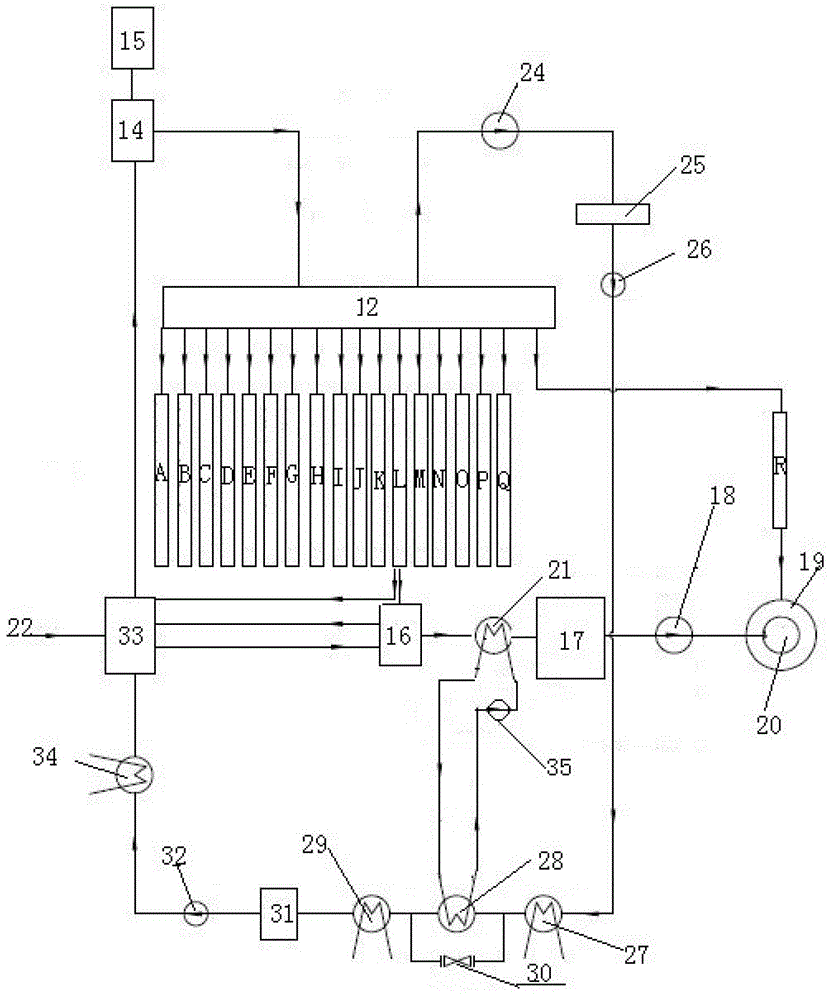

Embodiment 1

[0069] Provide boiler combustion air for boiler combustion user L.

[0070] It can save the heater investment and heater steam or hot water consumption, saving high-grade energy. The invention adopts a specially designed air-cooled center island, adopts integrally closed and multi-channel compartment forced ventilation cooling design, completely solves the problem of hot air backflow, and can realize air distribution for different waste heat utilization loads on demand at the same time.

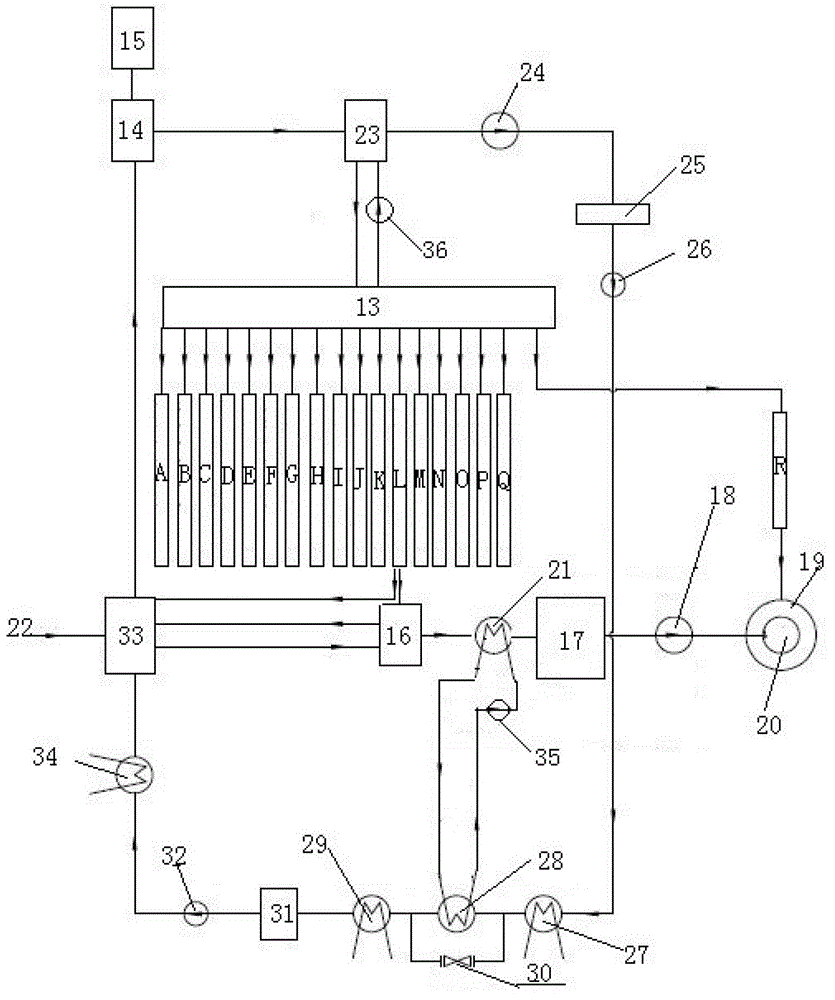

Embodiment 2

[0072] For external hot air heating user J hot air heating.

[0073] One of the traditional heating methods is to use heat and electricity combined cycle, and the heating medium is steam or water; the second traditional heating method is to use central air conditioning, and the heating medium is water or hot air. The heat source of the invention is a direct air-cooled center island, and the hot air after absorbing the waste heat of the steam power cycle is used for heating, and the waste heat of the steam power cycle can be used to realize the function of a large central air conditioner, thereby saving high-grade energy.

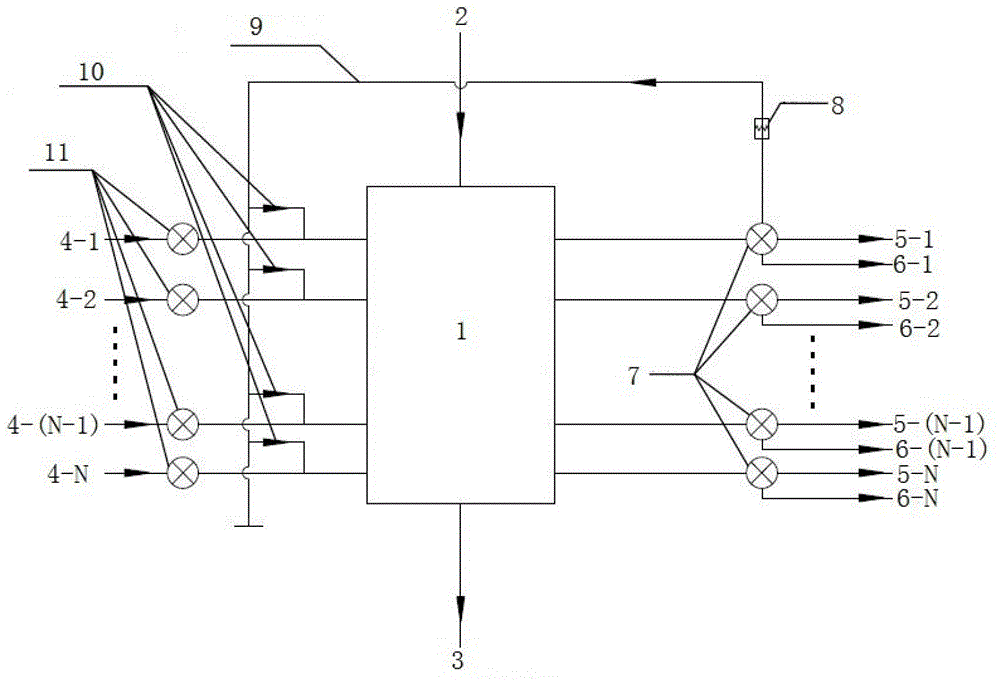

Embodiment 3

[0075] Conveying hot air for coal thawing user C in the power plant and coal thawing user E in the steel plant.

[0076] The traditional method is to use infrared, steam heating.

[0077] The invention uses a specially designed air-cooled central island to use a large amount of waste heat of the steam power cycle to raise the temperature of the ambient air first, and then heat it to above 100°C through the heater to be used for the coal thawing process, thus playing the role of energy saving. The heating source of the air heater can be steam, hot water, flue gas, high-temperature hot air, high-temperature oil and other medium heating or electric heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com