Method for immobilizing marine lipase Bohai Sea-9145 with magnetic Fe3O4@SiO2-NH2 nanoparticles

A technology of fe3o4sio2-nh2 and nano microspheres, which is applied in the field of marine microorganisms, can solve the problems of limiting the utilization of marine lipase, difficulties in the separation and purification of lipase, and poor stability of free enzymes, and achieves low production costs, high mechanical strength, and enzyme production. The effect of temperature stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

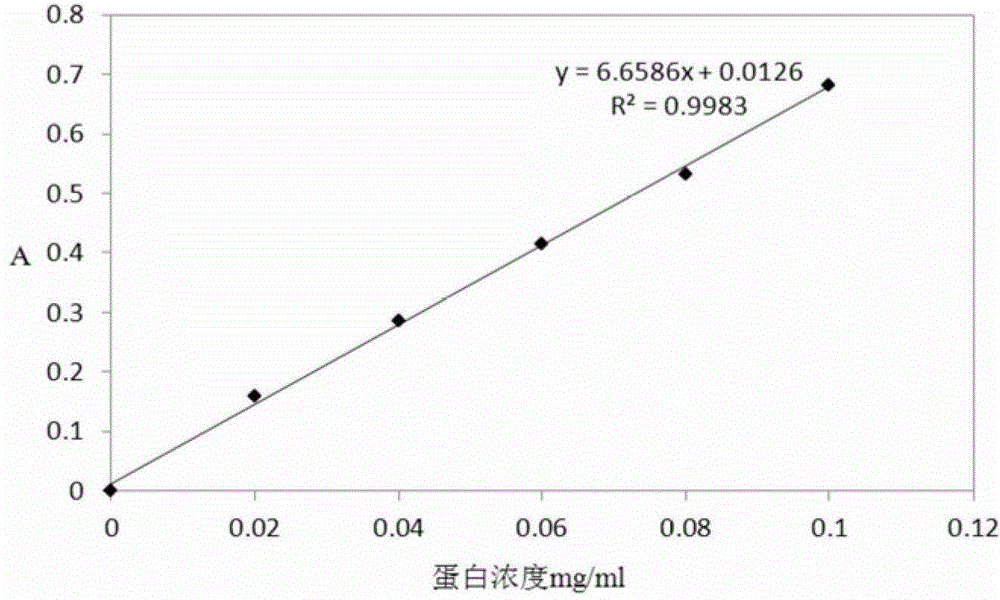

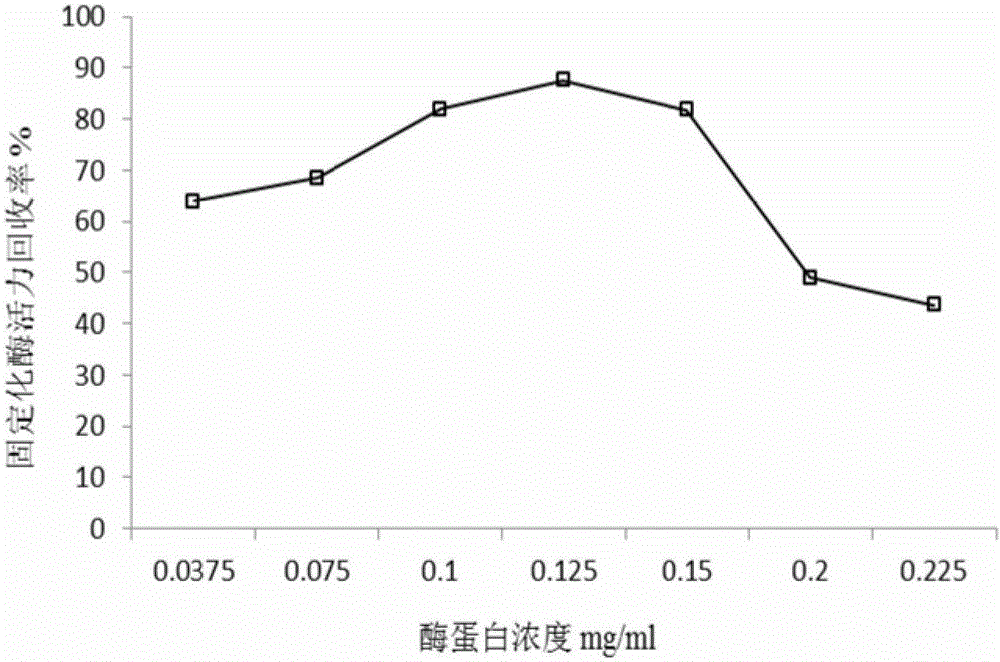

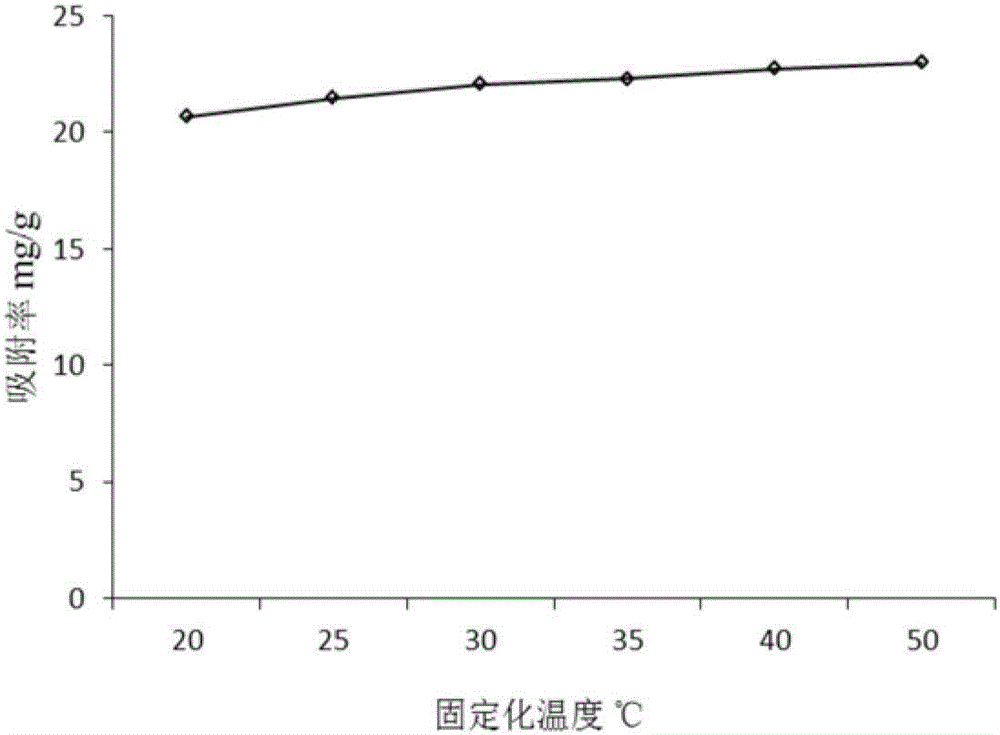

[0090] 10mg magnetic Fe 3 O 4 SiO 2 -NH 2 The nanospheres were placed in a 10ml vial, and then 2ml of lipase solution with an enzyme protein concentration of 0.125 mg / ml and an immobilization system of pH 8.0 was added to the vial, and the immobilization reaction temperature was 30°C on a shaker. Carry out the immobilization reaction for 10 hours, and then perform magnetic separation. Collect the supernatant and use it to determine the protein content. After washing the immobilized enzyme several times, until there is no protein content absorbed in the supernatant, the enzyme is used to determine the activity of the immobilized enzyme. The immobilized marine lipase Bohai Sea-9145 was obtained, the enzyme activity recovery rate was 87.7%, and the protein adsorption rate per unit area of the carrier was 23.7 mg / g.

Embodiment 2

[0092] 10mg magnetic Fe 3 O 4 SiO 2 -NH 2 Place the nanospheres in a 10ml vial, and then add 2ml of lipase solution with an enzyme protein concentration of 0.150 mg / ml, immobilization system pH of 7.0, and an immobilization reaction temperature of 25°C in the vial. Carry out the immobilization reaction for 12 hours, and then perform magnetic separation. Collect the supernatant and use it to determine the protein content. After washing the immobilized enzyme several times, until no protein content is absorbed in the supernatant, the enzyme is used to determine the activity of the immobilized enzyme. The immobilized marine lipase Bohai Sea-9145 was obtained, the enzyme activity recovery rate was 86.5%, and the protein adsorption rate per unit area of the carrier was 24.0 mg / g.

Embodiment 3

[0094] 10mg magnetic Fe 3 O 4 SiO 2 -NH 2 Nanospheres were placed in a 10ml vial, and 2ml of lipase solution with a concentration of 0.1mg / ml of enzyme protein and a pH of 7.0 for the immobilization system was added to the vial. The immobilization reaction temperature was 20℃, and the immobilization reaction was carried out on a shaker. After 14 hours, magnetic separation was performed, and the supernatant was collected and used to determine the protein content. After washing the immobilized enzyme several times, until no protein content was absorbed in the supernatant, the enzyme was used to determine the activity of the immobilized enzyme. Lipase Bohai Sea-9145 has an enzyme activity recovery rate of 81.0%, and a protein adsorption rate per unit area of the carrier is 22.0 mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com