A method for preparing multifunctional composite zno/in coated glass

A multifunctional and coating technology, which is applied in the field of preparing multifunctional composite ZnO/In coated glass, can solve the problems of affecting appearance, large dependence, and inconspicuous effect, and achieves low cost, enhanced hydrophobicity, and reduced production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

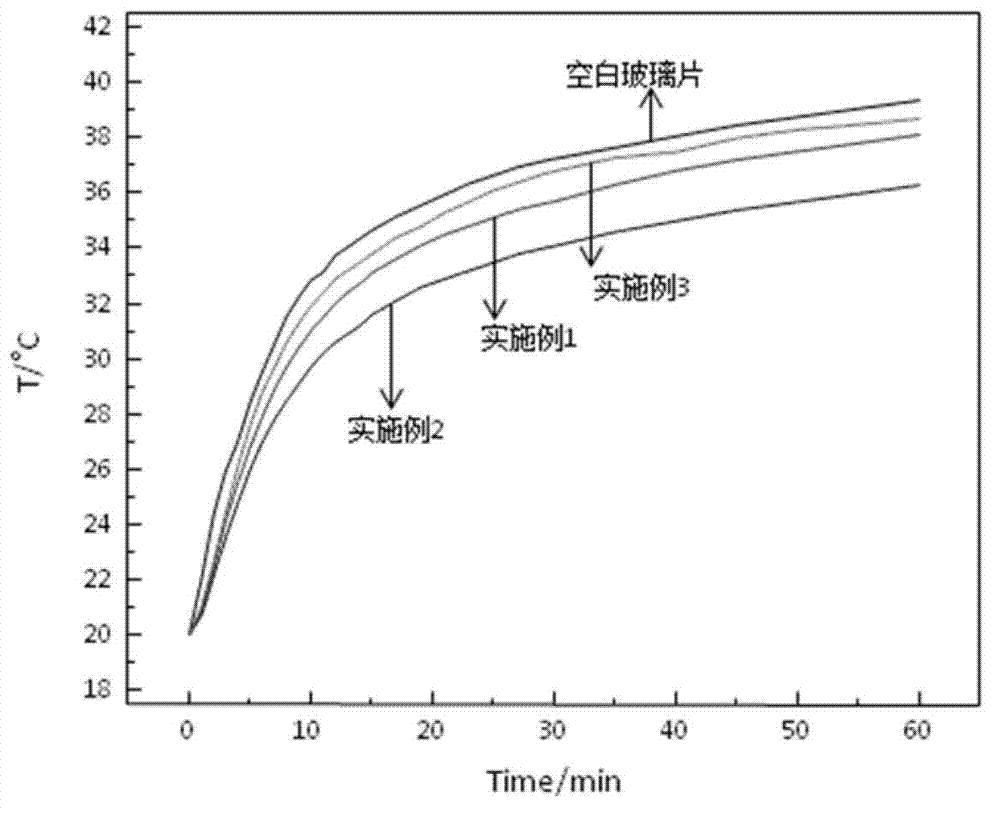

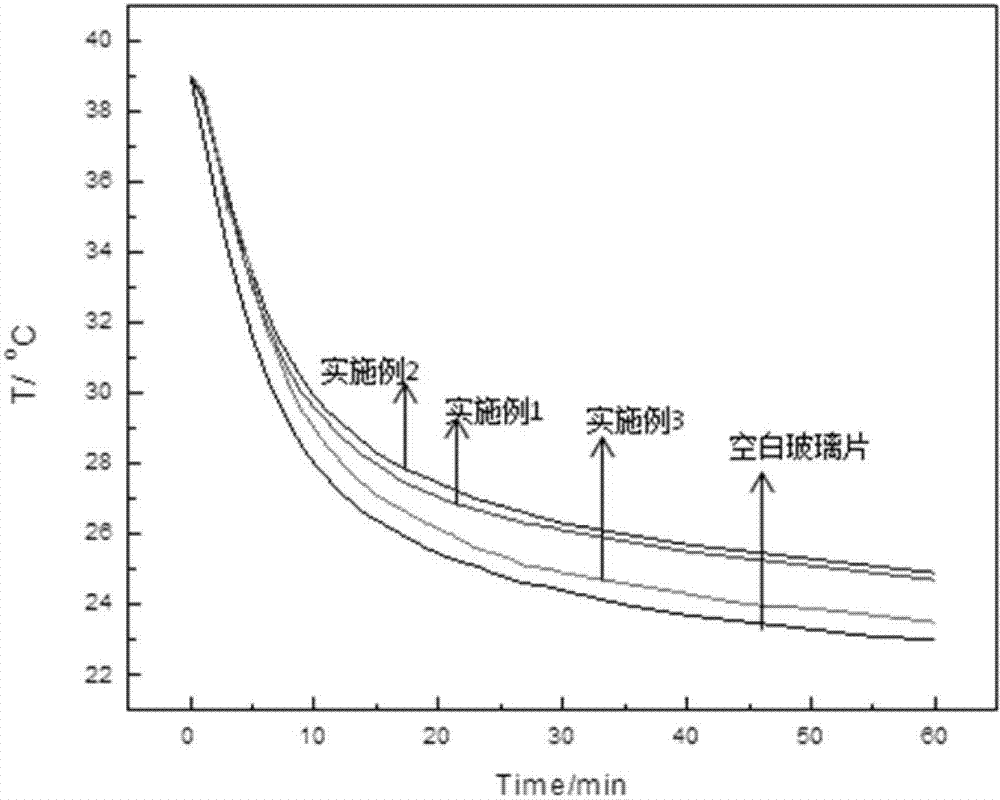

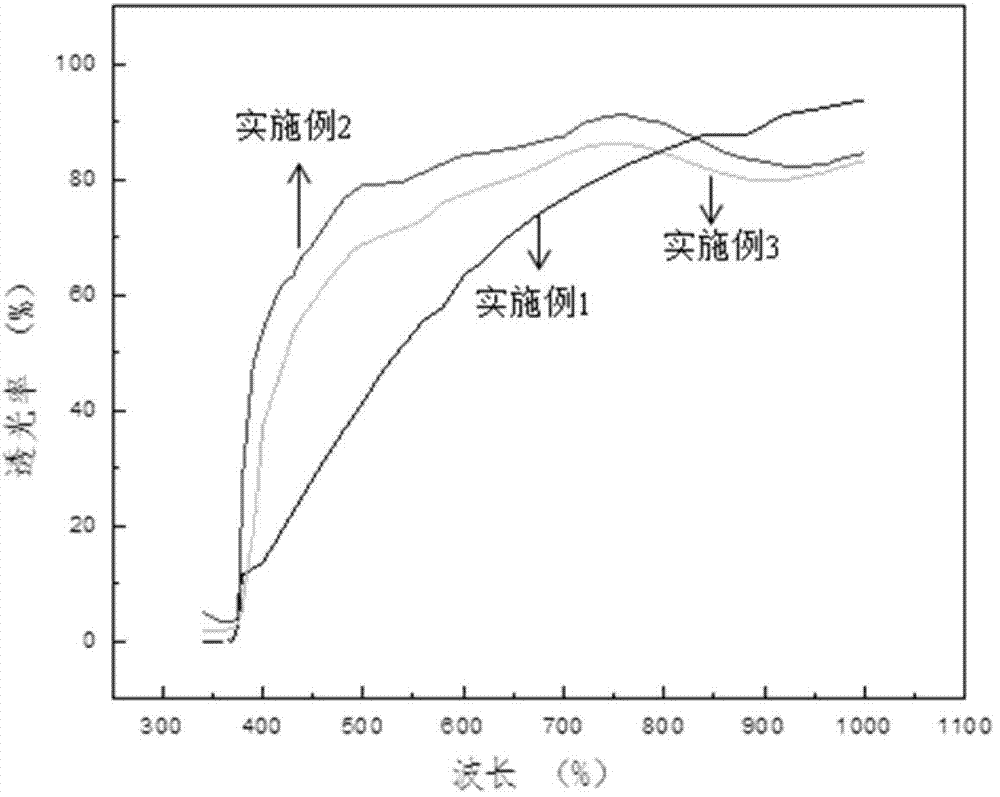

Embodiment 1

[0060] 1) Preparation of the seed layer precursor solution: Dissolve 21.95g of zinc acetate and 0.44g of indium chloride in 100mL of water, add 14g of aniline and stir, and disperse for 15min under ultrasonic power of 20KHz to obtain the seed layer precursor solution;

[0061] 2) Coating film: Spin coating is used to coat the precursor solution on the surface of the glass substrate. The specific process of spin coating is as follows: the spin coating temperature is 27°C, the dropping time is 18s, and the coating speed is 1800r / min. The glue equalization time is 20s; then dry to a dry film in a constant temperature drying oven at 60°C, and repeat the above coating and drying process 15 times;

[0062] 3) Heat treatment: raise the coated substrate from room temperature to 360°C at a rate of 50°C / min in an air atmosphere, keep it warm for 15 minutes, and then cool with the furnace;

[0063] 4) Configuration of hydrothermal solution: Dissolve 2.195g of zinc acetate and 0.063g of i...

Embodiment 2

[0066] 1) Preparation of seed layer precursor solution: Dissolve 21.95g of zinc acetate and 0.44g of indium chloride in 100mL of water, add 14.1g of hexamethylenetetramine, stir, and disperse for 20min under ultrasonic power of 20KHz to obtain Seed layer precursor solution;

[0067] 2) Coating film: The precursor solution is coated on the surface of the glass substrate by pulling coating, and the specific process of pulling coating is as follows: the pulling temperature is 25°C, the falling speed is 6mm / min, and the pulling speed is 0.6mm / min. min, the residence time in the solution is 3min; then dry to a dry film in a constant temperature drying oven at 60°C, and repeat the above coating and drying process 5 times;

[0068] 3) Heat treatment: heat the coated substrate from room temperature at 50°C / min to 200°C in an air atmosphere, keep it warm for 10 minutes, and then cool it in the furnace;

[0069] 4) Configuration of the hydrothermal reaction solution: Dissolve 2.195g of...

Embodiment 3

[0072] 1) Preparation of seed layer precursor solution: Dissolve 29.75g of zinc nitrate and 0.44g of indium chloride in 100mL of water, add 14.1g of hexamethylenetetramine and stir, and disperse for 10min under ultrasonic power of 20KHz to obtain Seed layer precursor solution;

[0073] 2) Coating film: the precursor solution is coated on the surface of the glass substrate by pulling coating, and the specific process of pulling coating is as follows: the pulling temperature is 25°C, the falling speed is 4mm / min, and the pulling speed is 1mm / min , the residence time in the solution is 5min; then dry to a dry film in a constant temperature drying oven at 80°C, and repeat the above coating and drying process 10 times;

[0074] 3) Heat treatment: raise the coated substrate from room temperature to 300°C at a rate of 50°C / min in an air atmosphere, keep it warm for 10 minutes, and then cool it in the furnace;

[0075] 4) Configuration of the hydrothermal solution: Dissolve 2.975g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com