Method for treating waste water containing sulfuric acid in production process of dyes and intermediates

A production process and wastewater treatment technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of stable operation, high degree of automation, and few supporting facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

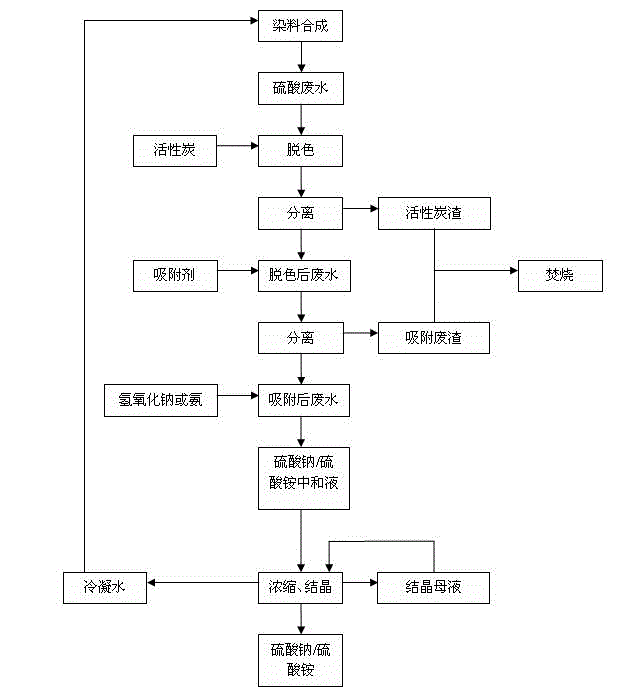

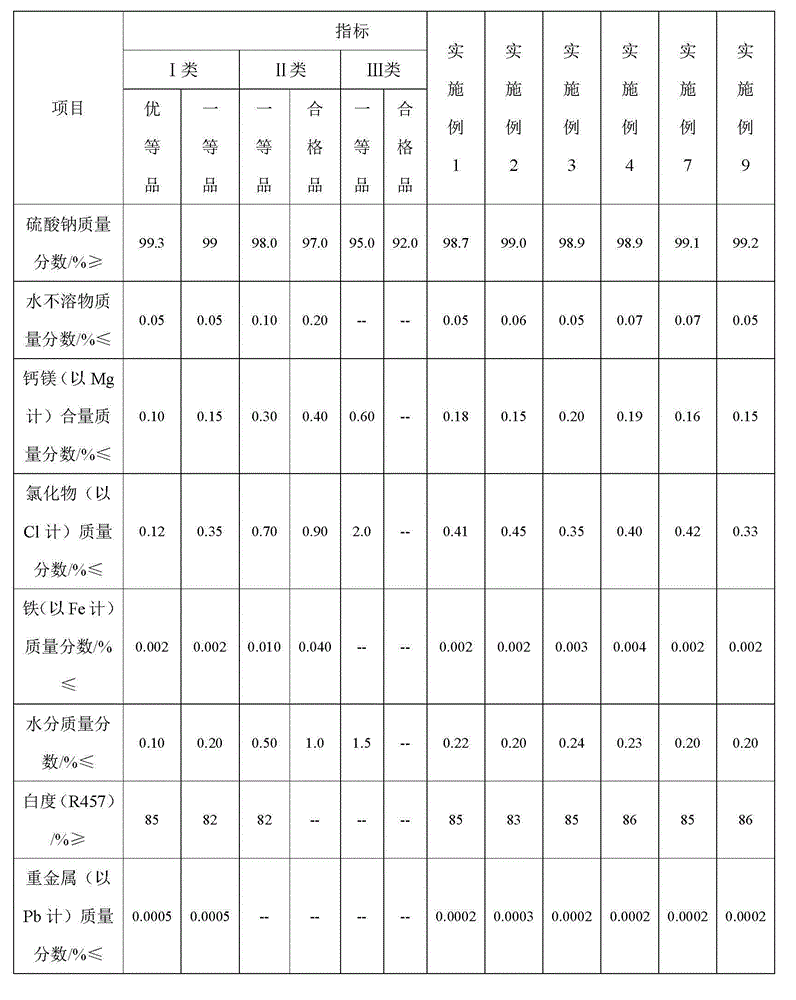

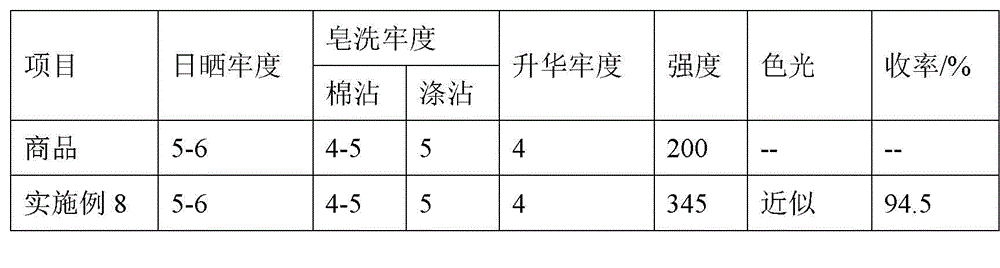

[0044] Process flow chart such as figure 1As shown, pump waste water containing sulfuric acid into the decolorization kettle (taken from the mother liquid water mixed in the production process of Disperse Blue 291:4 and Disperse Violet 93:4, the acidity of sulfuric acid is about 3%, and the color is 750 times), start stirring and add the quality of waste water 2.5% activated carbon adsorption decolorization, decolorization temperature is controlled at 45 ℃ ~ 50 ℃, heat preservation for 3 hours, sampling and filtration, the color of the filtrate is 9 times, and the decolorization is completed. Filtration and separation to obtain decolorized wastewater and activated carbon residue, pump the decolorized wastewater into the adsorption kettle, add polyacrylamide with 3% of the decolorized wastewater quality, control the temperature at 30°C to 35°C, keep for 1 hour, and filter to obtain the adsorption waste residue and The wastewater after adsorption is pumped into the neutralizatio...

Embodiment 2

[0047] Pump waste water containing sulfuric acid into the decolorization kettle (taken from the mother liquid water in the production process of Disperse Blue 291:4, the acidity of sulfuric acid is about 9%, and the color is 700 times), start stirring and add activated carbon with 1% mass of waste water containing sulfuric acid for decolorization, the decolorization temperature Control at 20°C to 25°C, keep warm for 1 hour, sample and filter, the color of the filtrate is 8 times, and the decolorization is completed. Filtration and separation to obtain decolorized wastewater and activated carbon slag, pump the decolorized wastewater into the adsorption kettle, add 0.05% EDTA of the decolorized wastewater quality, control the temperature at 20°C to 25°C, keep for 5 hours, filter to obtain the adsorption waste residue and the adsorbed Waste water: pump the waste water after adsorption into the neutralization tank, neutralize it with caustic soda (sodium hydroxide solid) to a pH va...

Embodiment 3

[0050] Pump waste water containing sulfuric acid into the decolorization kettle (taken from the mother liquid water in the production process of Disperse Red FBS, the acidity of sulfuric acid is about 16%, and the color is 900 times), start stirring and add activated carbon with 5% mass of waste water containing sulfuric acid for decolorization, and control the decolorization temperature At 65°C-70°C, keep warm for 5 hours, sample and filter, the filtrate chroma is 22 times, filter and separate to obtain decolorized wastewater and activated carbon residue, pump the decolorized wastewater into the adsorption kettle, add hexametaphosphoric acid with 5% of the decolorized wastewater quality Sodium, the temperature is controlled at 45°C to 50°C, keep it for 5 hours, filter the adsorption waste residue and the wastewater after adsorption, add 30% hydrogen peroxide to the wastewater after adsorption for oxidation, the amount of hydrogen peroxide is 0.1% of the quality of the wastewate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com