A kind of recovery process of carbon disulfide in viscose fiber production

A technology of carbon disulfide and viscose fiber, which is applied in the direction of carbon disulfide, carbon sulfur compounds, chemical instruments and methods, etc., and can solve the problems of low mass and heat transfer capacity, high operating cost and investment cost, and irritation , to achieve high degree of automation, low investment and operating costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

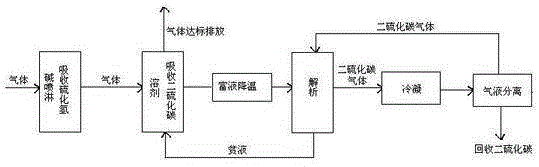

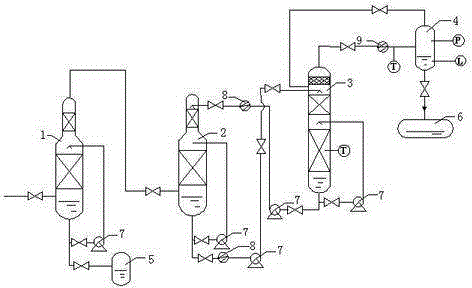

[0043] A process for recovering carbon disulfide in viscose fiber production, wherein the carbon disulfide waste gas produced in viscose fiber production is sprayed with alkali to remove hydrogen sulfide in the waste gas, and then the carbon disulfide is recovered through the following process steps:

[0044] A absorbs carbon disulfide

[0045] Use white oil as an absorbent to absorb carbon disulfide in the exhaust gas, and cool down the saturated carbon disulfide-rich liquid to 15°C;

[0046] B analysis

[0047] The saturated carbon disulfide-rich liquid enters the desorption tower through the pump, and is heated to 150°C after passing through the liquid distributor. It is easy to boil under heating and is separated from the absorbent to form carbon disulfide gas and lean liquid;

[0048] C recycling

[0049] The carbon disulfide gas is condensed and gas-liquid separated to recover the condensed carbon disulfide.

Embodiment 2

[0051] A process for recovering carbon disulfide in viscose fiber production, wherein the carbon disulfide waste gas produced in viscose fiber production is sprayed with alkali to remove hydrogen sulfide in the waste gas, and then the carbon disulfide is recovered through the following process steps:

[0052] A absorbs carbon disulfide

[0053] Use white oil as an absorbent to absorb carbon disulfide in the exhaust gas, and cool down the saturated carbon disulfide-rich liquid to 35°C;

[0054] B analysis

[0055] The saturated carbon disulfide rich liquid enters the desorption tower through the pump, and is heated to 170°C after passing through the liquid distributor, boils under heating, and is separated from the absorbent to form carbon disulfide gas and lean liquid;

[0056] C recycling

[0057] The carbon disulfide gas is condensed and gas-liquid separated to recover the condensed carbon disulfide.

Embodiment 3

[0059] A process for recovering carbon disulfide in viscose fiber production, wherein the carbon disulfide waste gas produced in viscose fiber production is sprayed with alkali to remove hydrogen sulfide in the waste gas, and then the carbon disulfide is recovered through the following process steps:

[0060] A absorbs carbon disulfide

[0061] Use white oil as an absorbent to absorb carbon disulfide in the exhaust gas, and cool down the saturated carbon disulfide-rich liquid to 30°C;

[0062] B analysis

[0063] The saturated carbon disulfide rich solution enters the desorption tower through the pump, and after passing through the liquid distributor, the carbon disulfide rich solution first slowly rises to 140°C at a speed of 12°C / min, and then rises to 160°C within 1 minute, and keeps the temperature for 30 minutes. Boiling under heating, separating to form carbon disulfide gas and lean liquid;

[0064] C recycling

[0065] The carbon disulfide gas is condensed and gas-li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com