Larva clamping machine for mechanized production of royal jelly

A technology of royal jelly and worm-clamping machine, which is applied in application, beekeeping, animal husbandry and other directions, can solve problems such as labor consumption, and achieve the effects of improving production efficiency, reducing costs and being easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

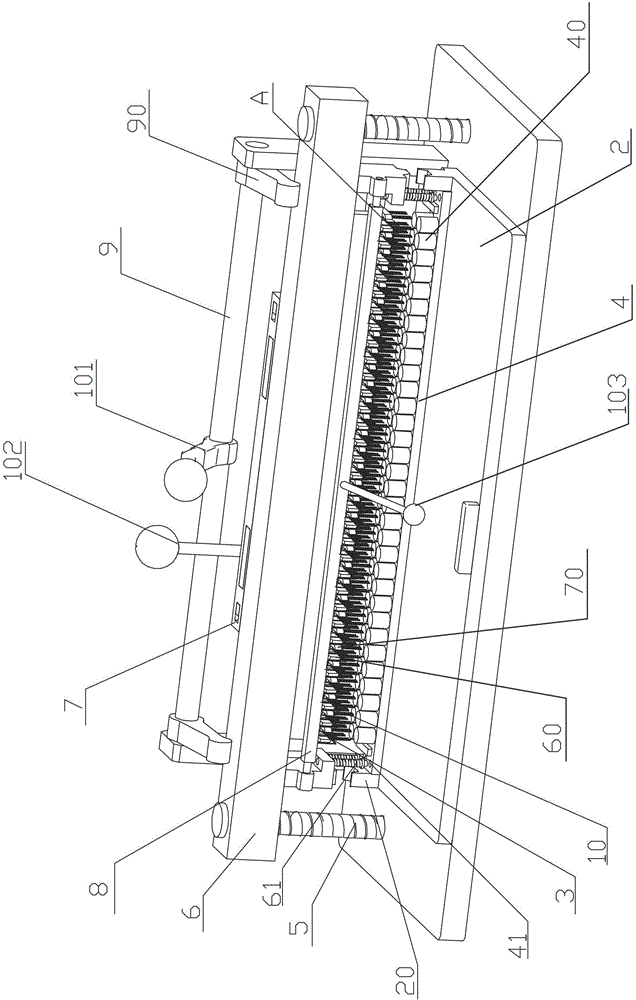

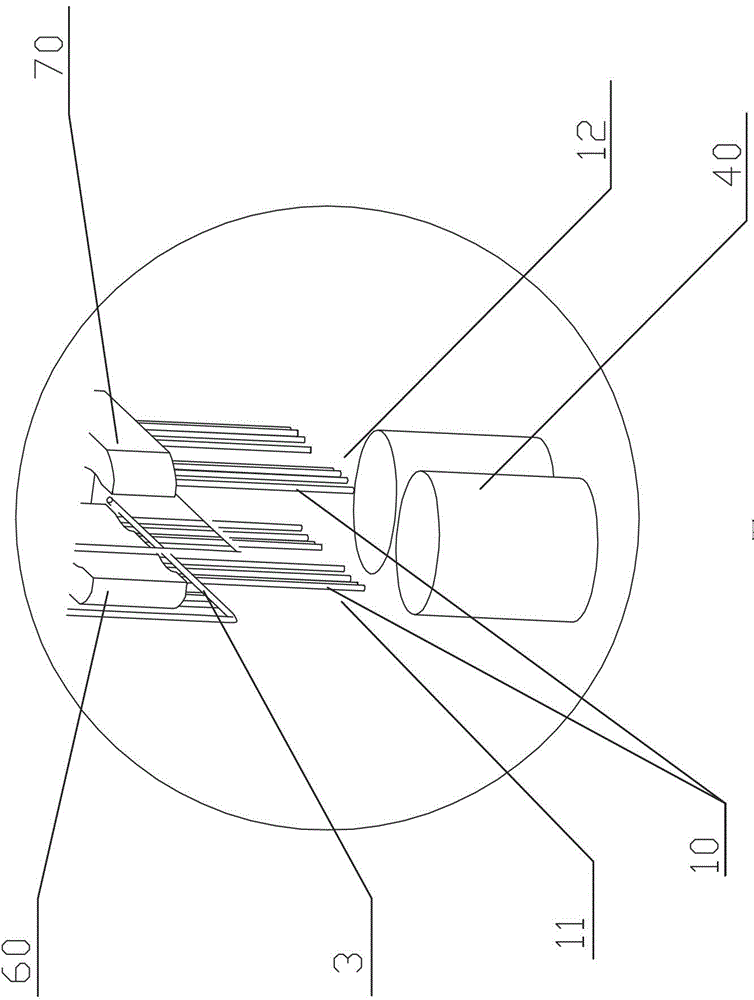

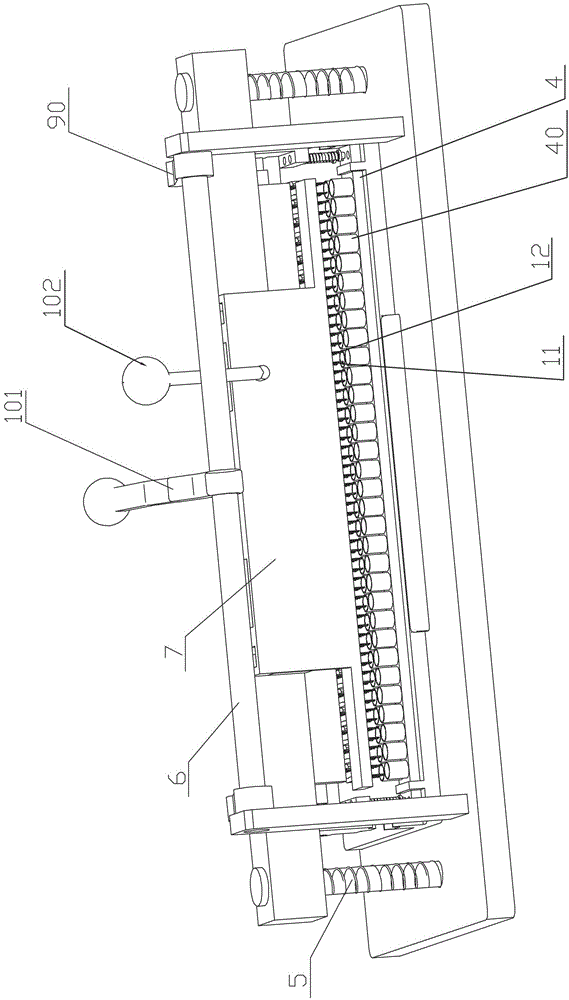

[0027] Refer to attached picture. The pincers machine for the mechanized production of royal jelly provided by the present invention comprises pincers mechanisms arranged in a row, the pincers mechanism is composed of left pincers parts 11 and right pincers parts 12, and is arranged below the pincers mechanism Table base bar table 2; the left pincer part 11 and the right pincer part 12 are all made of several vertical steel wires 10, and one of the left pincer part and the right pincer part is movable relative to the other As for the movable pincer parts, the number of vertical steel wires can be 1 or more, such as 2, 3, 4, 5, etc., but especially 4 is the best, which has achieved the accuracy and reliability of the pincers. , Avoid the comprehensive balance of pulping and insect damage. And when the several vertical steel wires are arranged in a slightly arc shape, the effect is better.

[0028] Adopting the steel wire as the pincer worm part is a technical means of utilizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com