MOS super barrier rectifier device and manufacturing method thereof

A rectifier device and super-barrier technology, which is applied in the field of power semiconductor devices, can solve the problems of device reliability reduction, semiconductor surface damage, high injection energy, etc., and achieve the goals of reducing reverse leakage current, improving stability, and reducing turn-on voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below through specific embodiments.

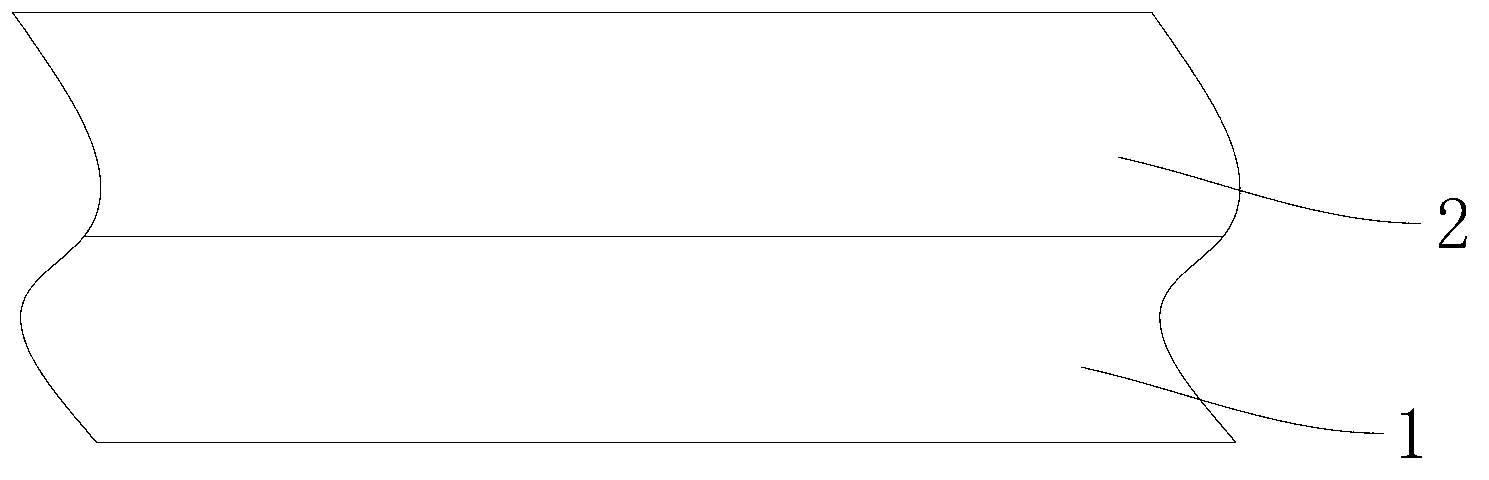

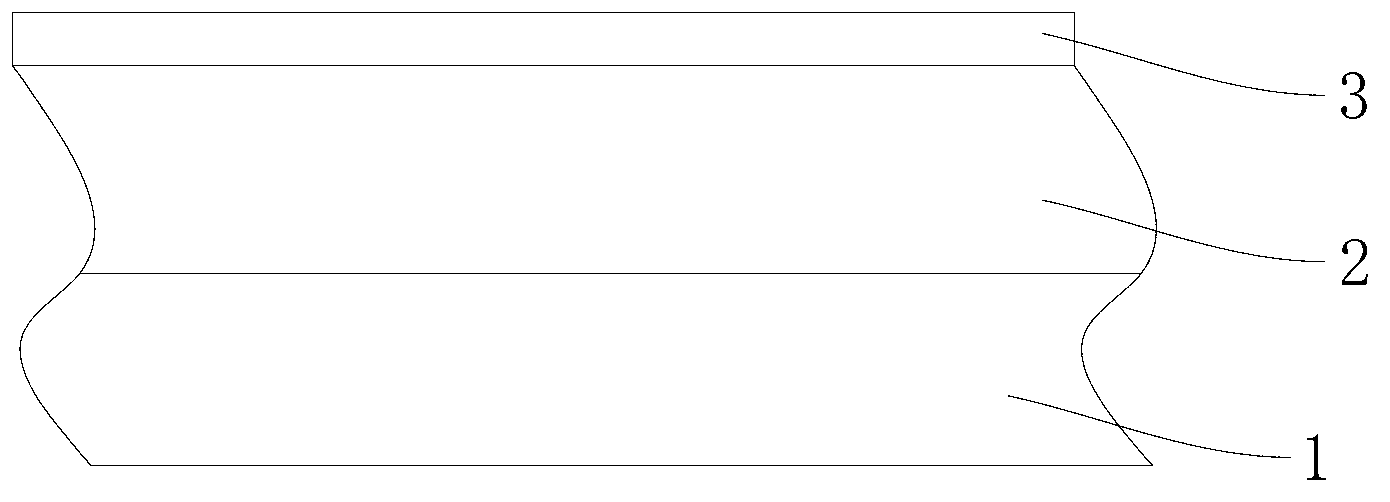

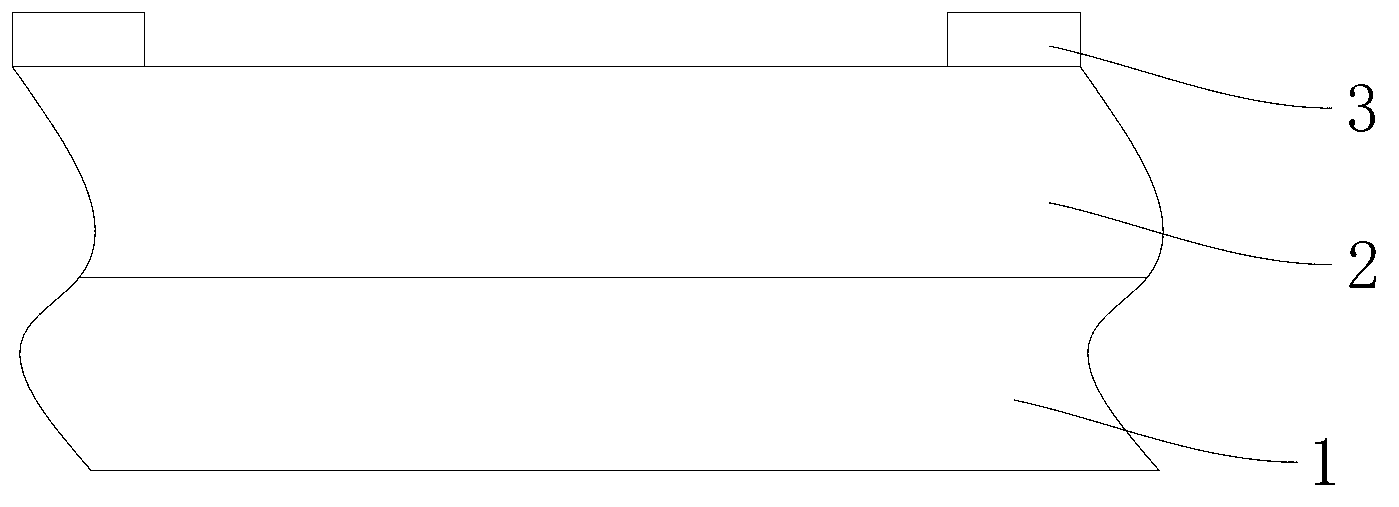

[0043] A MOS super-barrier rectifier device, such as Figure 12 As shown, the cross section of the rectifier device includes a semiconductor substrate, the lower part of the semiconductor substrate is a heavily doped first conductivity type substrate 1, the upper part of the semiconductor substrate is a lightly doped first conductivity type drift region 2, the The impurities of the first conductivity type may be N-type impurities, and correspondingly, the impurities of the second conductivity type mentioned below are P-type impurities, and vice versa. In this embodiment, the first conductivity type impurities are N-type impurities, and the second conductivity type impurities are P-type impurities. The upper surface of the semiconductor substrate is defined as the first surface, the lower surface of the semiconductor substrate is defined as the second surface, and the edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com