Method for evaluating attenuation degree of porous asphalt mixture void

A technology of drainage asphalt and attenuation degree, which is applied in the field of evaluating the void attenuation degree of drainage asphalt mixture, can solve the problems such as the lack of systematic research and the decay of pore structure, and achieves a simple test operation process and is easy for engineering and technical personnel to grasp. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

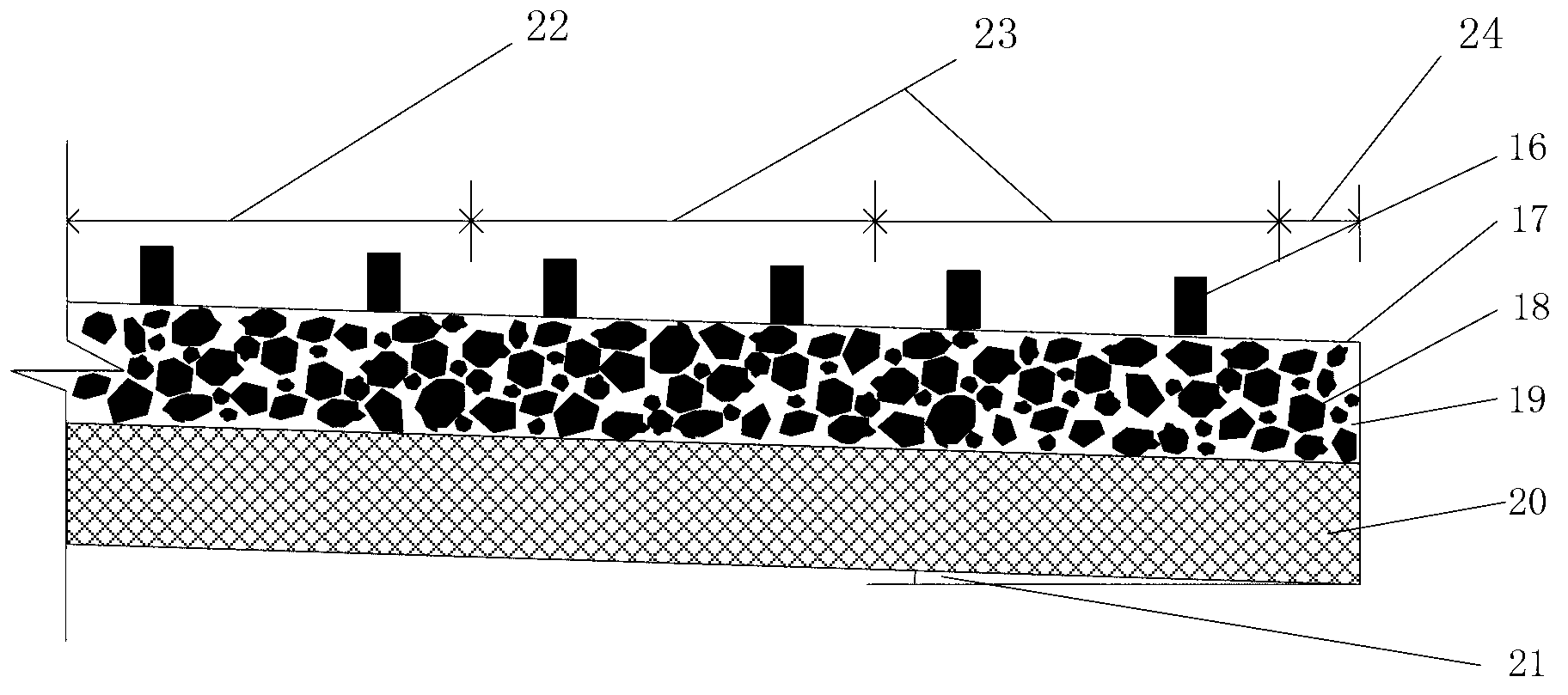

[0037] Embodiment: The evaluation method of the void attenuation degree of drainage asphalt mixture OGFC-13 comprises the steps:

[0038] (1) Forming of drainage asphalt mixture plate specimen

[0039] The gradation used in the drainage asphalt mixture OGFC-13 to be evaluated is shown in Table 2, and its target void ratio is 20%. The asphalt mixture is used for the upper layer of an expressway, and the cross slope is 1.5%. According to the design method of drainage asphalt mixture, the asphalt ratio of OGFC-13 mixture finally determined by leakage test and flying test is 4.9%.

[0040] Table 2 Gradation of drainage asphalt mixture OGFC-13

[0041]

[0042] According to the gradation shown in Table 2 and the asphalt ratio of 4.9%, the asphalt mixture is mixed, and the mixed mixture is put into the steel mold used for the rutting test plate, and the asphalt mixture is formed by wheel rolling. The plate-type test piece of the material, the size of the test piece is 300mm lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com