LED lamp

A technology of light-emitting diodes and lamps, which is applied to light sources, electric light sources, point light sources, etc., can solve the problems of easy corrosion of chips, single heat dissipation path, and unsatisfactory heat dissipation effect, and achieve high selectivity, prolong life, and improve heat dissipation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

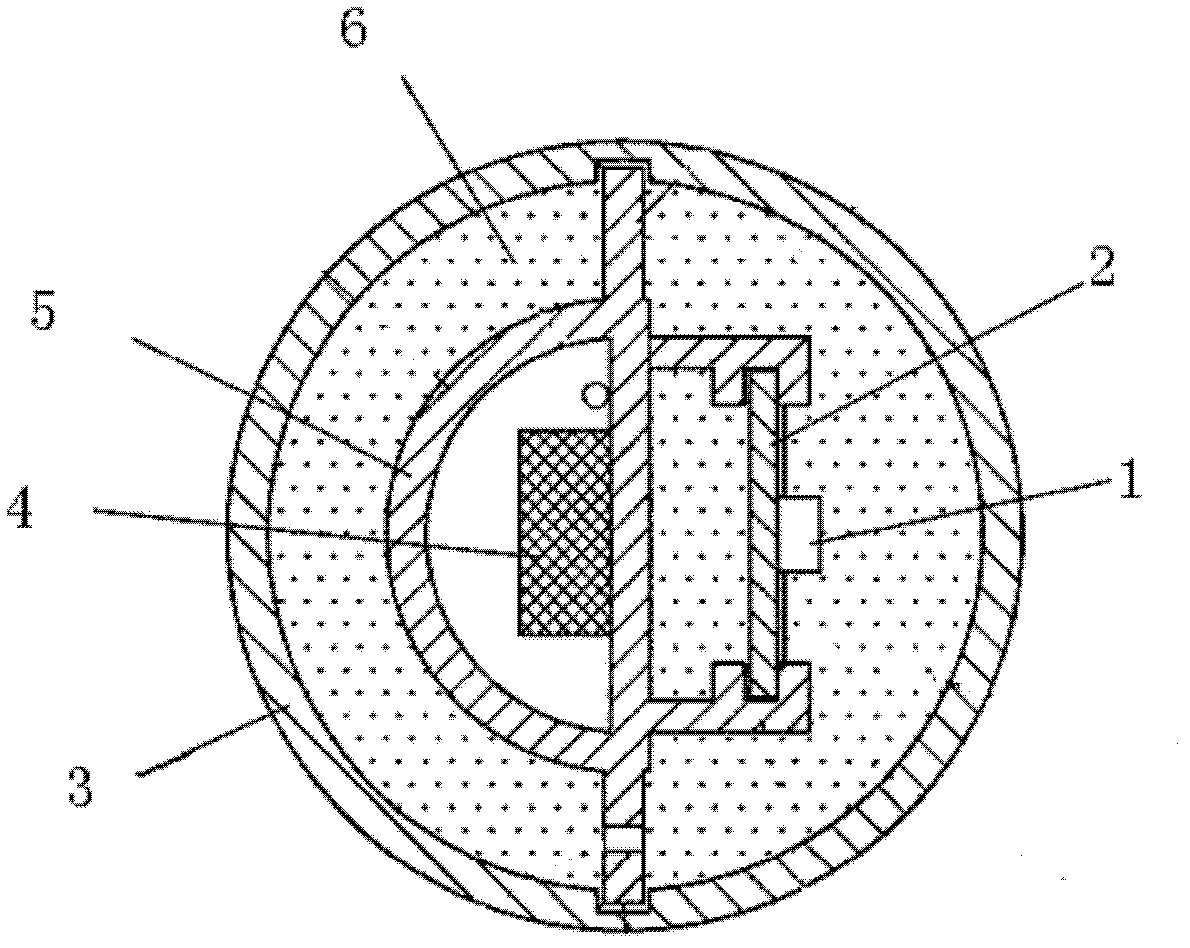

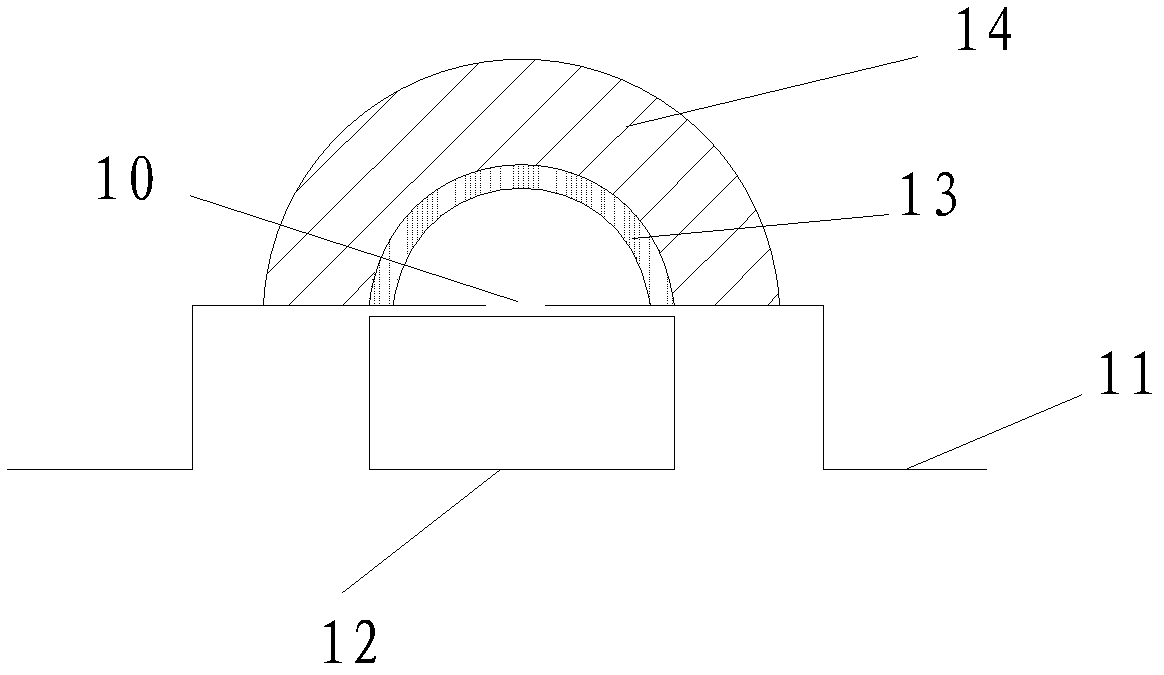

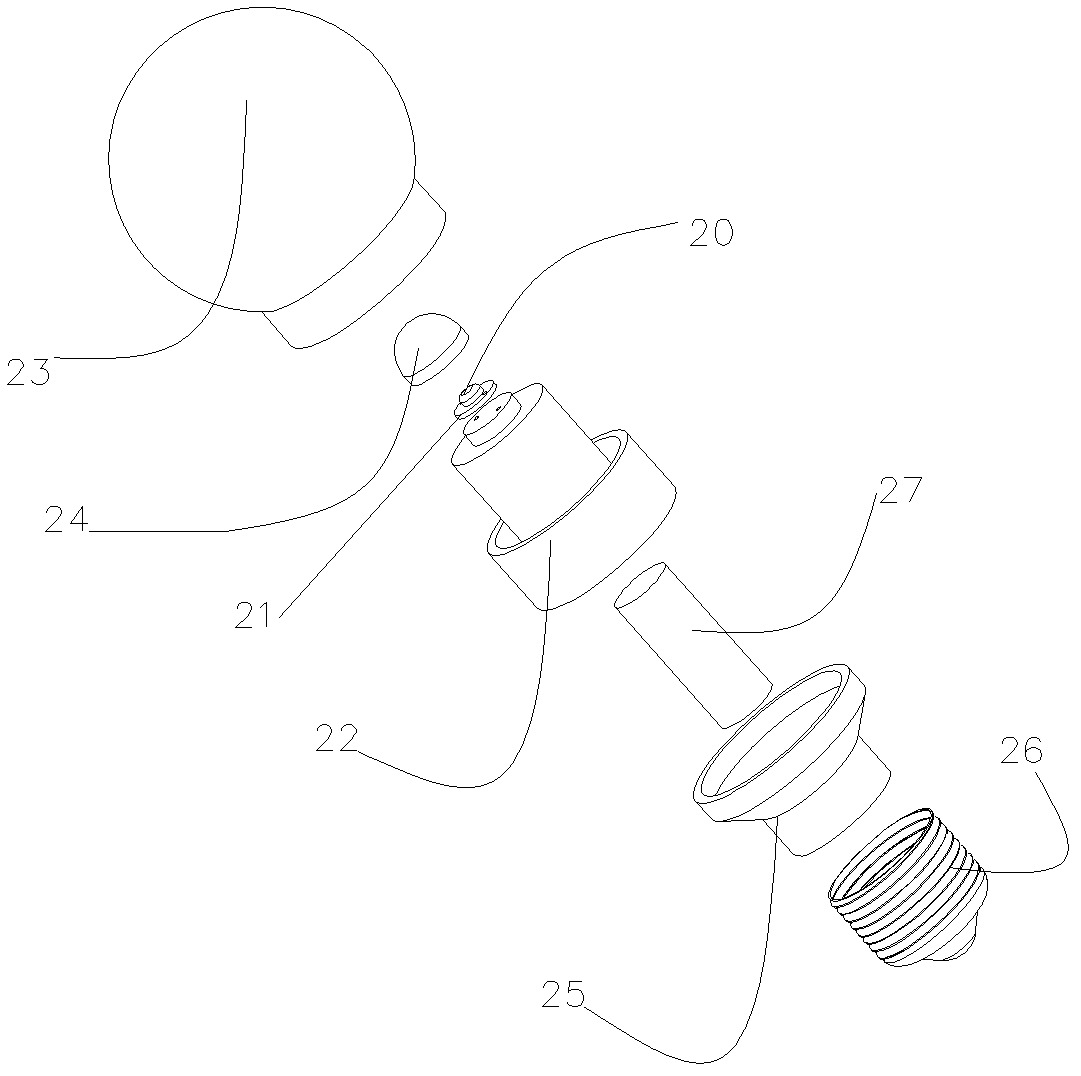

[0047] refer to image 3 with Figure 4 , are respectively an exploded view and a schematic cross-sectional view of the bulb-shaped LED lamp according to Embodiment 1 of the present invention.

[0048] combine image 3 with Figure 4 As shown, the bulb-shaped LED lamp of Embodiment 1 of the present invention includes: LED light source 20 , LED substrate 21 , substrate base 22 , outer light distribution cover 23 , inner sealing cover 24 , lamp holder connector 25 , lamp holder 26 and driver 27 . The outer surface of the inner sealing cover 24 is sprayed with fluorescent powder, the inner sealing cover 24 is hemispherical, and the outer light distribution mask 23 is bulb-shaped.

[0049] The LED substrate 21 is arranged on the base base 22 , and the LED light source 20 is fixed on the LED substrate 21 .

[0050] The inner sealing cover 24 sprayed with phosphor is arranged on the top of the substrate seat 22, the inner surface of the inner sealing cover 24 and the top of the ...

Embodiment 2

[0064] see Figure 7 , is a schematic cross-sectional view of the flame-shaped LED lamp of this embodiment, including: LED light source 30, LED substrate, substrate base 31, outer light distribution cover 32, inner sealing cover 33, lamp cap 35, lamp cap connector 36 and driver 37. The inner sealing cover 24 is flame-shaped, and the outer photomask 23 is flame-shaped. The inner sealing cover 33 has fluorescent powder, especially, the fluorescent powder is molded together with materials such as plastic or glass, so that the fluorescent powder is evenly distributed in the material of the inner sealing cover.

[0065] The LED substrate is arranged on the substrate seat 31, and the two LED light sources 30 are fixed on the LED substrate. In this embodiment, two LED light sources are fixed on the LED substrate, and one or more LED light sources may also be used.

[0066] The inner sealing cover 33 with fluorescent powder is arranged on the top of the substrate seat 31, the inner ...

Embodiment 3

[0077] see Figure 9 , is a schematic cross-sectional view of the bar-shaped LED lamp of this embodiment. The bar-shaped LED lamp mainly includes: an LED light source 60 , an LED substrate 61 , a substrate base 62 , an external light distribution cover 63 , an internal sealing cover 64 and a driver 65 . The inner sealing cover 64 may be in a semi-cylindrical shape, and the outer light distribution cover 23 may be in a cylindrical shape.

[0078] The LED substrate 61 is arranged on the base 62 , and one or more LED light sources 60 are welded on the LED substrate 61 .

[0079] The inner sealing cover 64 is arranged on the top of the substrate seat 62, the inner surface of the inner sealing cover 64 and the top of the substrate seat 62 form a first sealed cavity 601, and the LED substrate 61 is sealed in the first sealed cavity 601, close to the top of the substrate seat 62.

[0080] The outer light distribution cover 63 is arranged on the outside of the substrate base 62, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com