A kind of magnesium alloy micro-arc oxidation solution formula and its application method

A technology of micro-arc oxidation and magnesium alloy, applied in the direction of anodic oxidation, can solve the problem of unfavorable corrosion resistance of oxide layer, and achieve the effect of improving micro-arc discharge characteristics, high corrosion resistance level and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

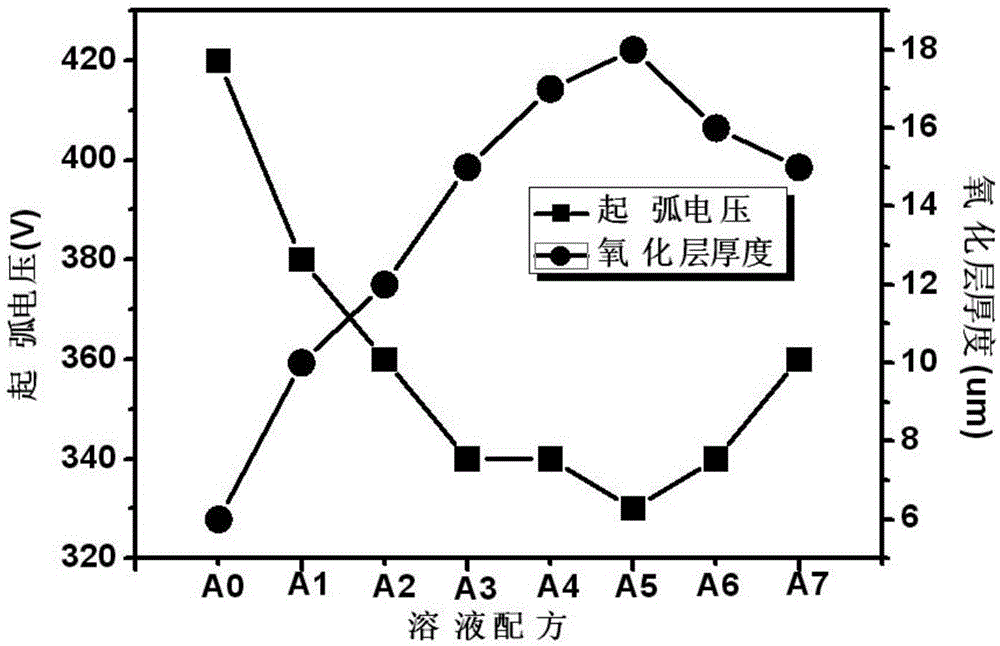

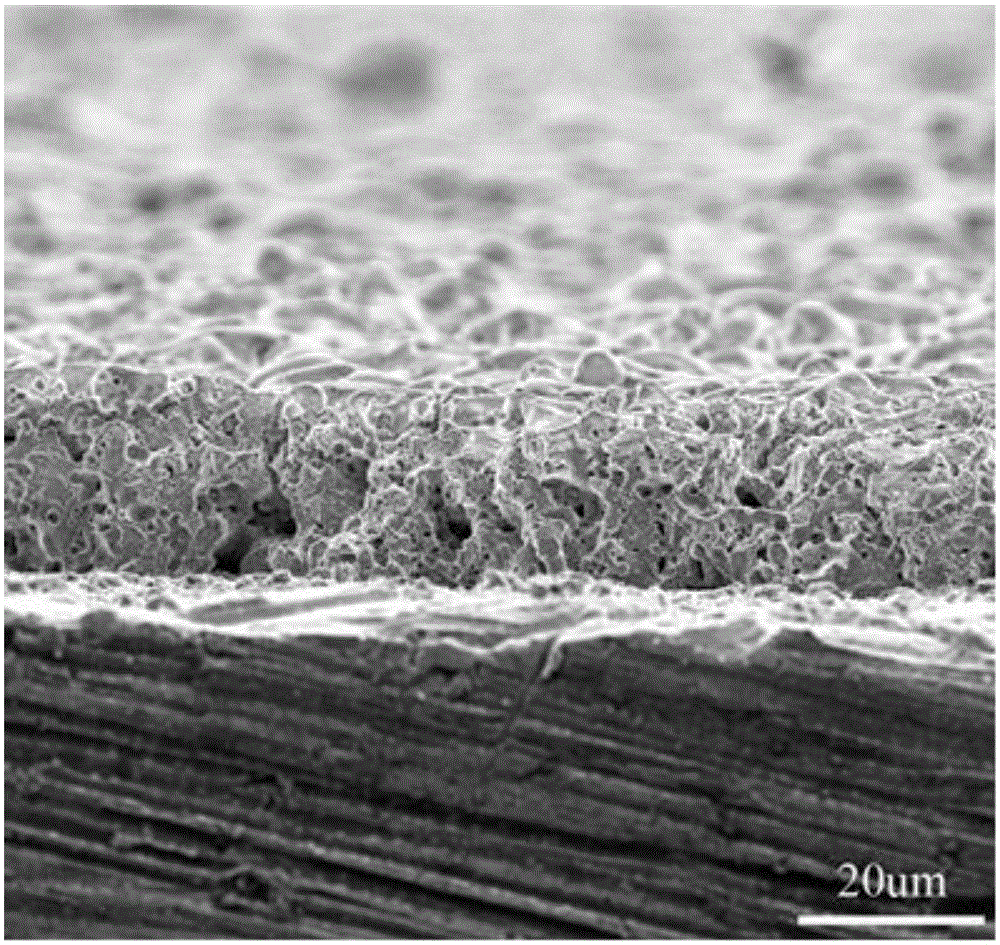

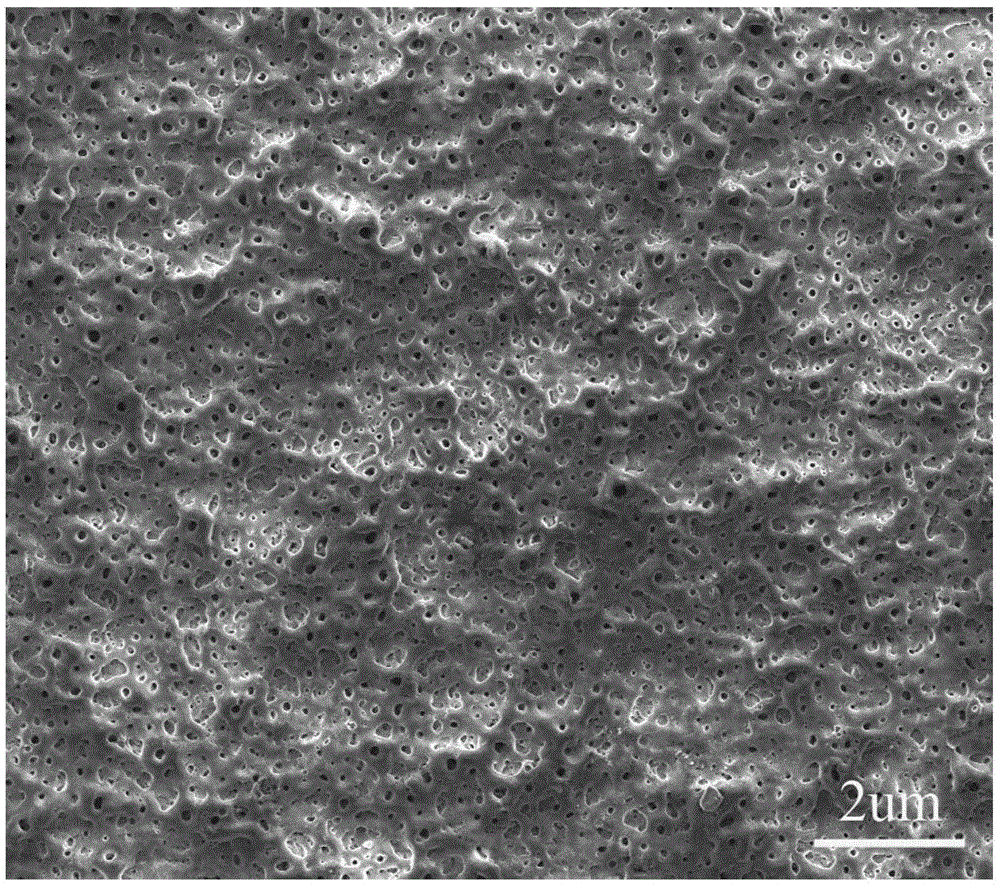

[0020] figure 1 In the specific embodiment of the present invention, the formula of the micro-arc oxidation solution, the arc starting voltage, and the relationship diagram of the thickness of the corrosion-resistant layer; figure 2 It is the scanning electron microscope topography figure of the magnesium alloy cross section after micro-arc oxidation in the specific embodiment of the present invention; image 3 In the specific embodiment of the present invention, the scanning electron microscope topography figure of the magnesium alloy surface after micro-arc oxidation; Table 1 is in the specific embodiment of the present invention, the relationship between the formula of the micro-arc oxidation solution, the arc starting voltage, the current density, and the thickness of the corrosion-resistant layer surface.

[0021]

[0022]

[0023] As shown in Table 1, according to the formulas of A0-A7, various solutes or their hydrates of different qualities were added to deioni...

Embodiment 2

[0025] Table 2 is a relationship table of micro-arc oxidation parameters, corrosion-resistant layer thickness and corrosion-resistant grade in the specific embodiment of the present invention.

[0026]

[0027]

[0028] Using the A3 formula in Table 1 (i.e. 3g / LKOH, 10g / LNa 2 SiO 3 10H 2 O, 3g / LNa 3 AlO 3 , 3g / LNaF, 3ml / L triethanolamine and 0.5gNa 2 B 4 o 7 ), the magnesium alloy was cleaned according to the method in Example 1, the temperature of the micro-arc oxidation solution was controlled to be lower than 60°C, the power pulse frequency was 200Hz, and the duty cycle was 20%. , 380V and 410V for micro-arc oxidation for 15 minutes, and the thicknesses of the corrosion-resistant layers obtained are 6 μm, 12 μm, 15 μm, 18 μm and 21 μm respectively; using the YWX / LX-120 salt spray test chamber produced by Shanghai Luxuan Instrument and Equipment Factory, According to GB / T10125-1997 Medium Salt Spray Test Standard (NSS), the corrosion resistance of the micro-arc ...

Embodiment 3

[0030] Using the formula A3 in Table 1, clean the magnesium alloy according to the method in Example 1, the temperature of the micro-arc oxidation solution is lower than 60 ° C, the electrode settings are the same as in Example 1, the frequency of use is 200 Hz, the voltage is 350 V, and the duty cycle is 5%, 10%, 20%, 30%, 40% and 50% of the pulse power supply were subjected to micro-arc oxidation for 15 minutes, and the thicknesses of the corrosion-resistant layers obtained were 7 μm, 11 μm, 13 μm, 16 μm, 19 μm and 21 μm; according to Example 2 The methods used to test and evaluate the corrosion resistance grades of the corrosion-resistant layer are 8, 8, 8, 8, 8 and 7 (as shown in schemes B6-B11 in Table 2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com