Aluminum alloy medium plate preparation method

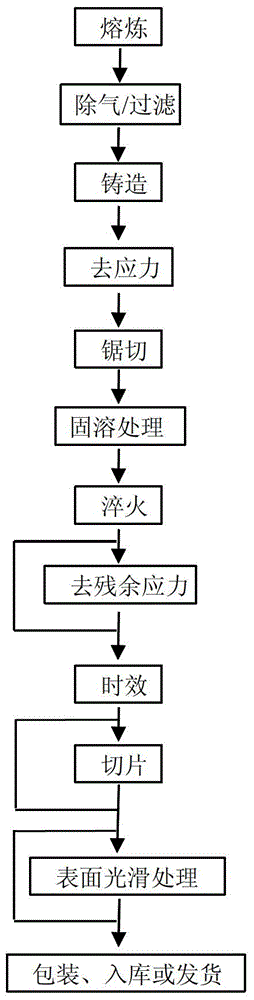

An aluminum alloy substrate and aluminum alloy technology, which is applied in the field of non-ferrous metal processing, can solve the problems of uneven structure and performance of the plate in the high direction, the surface deformation is larger than that of the core, and the mechanical properties of the alloy are low, so as to achieve good product quality and organization. Uniform, high performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put 50 tons of raw materials into the melting furnace: the melting temperature is 740°C to 750°C. After the alloy is completely melted, the composition and content (% by weight) of the aluminum alloy are controlled as follows: Si 0.05, Mg 2.36, Cu 1.54, Cr 0.21, Ti 0.03; Mn 0.03, Fe 0.08, Zn 5.52, V 0.02, Zr 0.01, and the rest The amount is Al. A multi-stage degassing purification system is used to degas the melt, and then a 30ppi foam ceramic filter plate is used to filter the melt, and an aluminum alloy ingot with a thickness of 420mm is obtained after casting. The aluminum alloy ingot is subjected to stress relief treatment at 450°C for 12 hours, then the head and tail of the stress relieved aluminum alloy ingot are cut off, sawed into 121mm thick aluminum alloy plate, and then the aluminum alloy plate is subjected to 4 hours at 470°C Solution treatment, and quenching immediately, after quenching the aluminum alloy plate, remove the quenching residual stress, and co...

Embodiment 2

[0033] Put 50 tons of raw materials into the melting furnace: the melting temperature is 700°C to 720°C. After the alloy is completely melted, the composition and content (% by weight) of the aluminum alloy are controlled as follows: Si 0.01, Mg 1.99, Cu 2.14, Cr 0.03, Ti 0.03; Mn 0.01, Fe 0.10, Zn 6.17, V 0.03, Zr 0.09, and the rest The amount is Al. A multi-stage degassing purification system is used to degas the melt, and then a 30ppi foam ceramic filter plate is used to filter the melt, and an aluminum alloy ingot with a thickness of 420mm is obtained after casting. The aluminum alloy ingot is subjected to stress relief treatment at 400°C for 20 hours, then the head and tail of the stress relieved aluminum alloy ingot are cut off, sawed into 121mm thick aluminum alloy plate, and then the aluminum alloy plate is subjected to 4 hours at 470°C Solution treatment, and quenching immediately, after quenching the aluminum alloy plate, remove the quenching residual stress, and co...

Embodiment 3

[0036] Put 50 tons of raw materials into the melting furnace: the melting temperature is 700°C to 710°C. After the alloy is completely melted, the composition and content (% by weight) of the aluminum alloy are controlled as follows: Si 0.08, Mg 1.99, Cu 0.18, Cr 0.33, Ti 0.05; Mn 0.45, Fe 0.17, Zn 4.2, V 0.04, Zr 0.16, the rest The amount is Al. A multi-stage degassing purification system is used to degas the melt, and then a 30ppi foam ceramic filter plate is used to filter the melt, and an aluminum alloy ingot with a thickness of 520mm is obtained after casting. The aluminum alloy ingot is subjected to stress relief treatment at 470°C for 5 hours, then the head and tail of the stress relieved aluminum alloy ingot are cut off, sawed into 251mm thick aluminum alloy plate, and then the aluminum alloy plate is subjected to 2 hours at 470°C Solution treated and immediately quenched. The plate is subjected to aging treatment at 150°C for 16 hours, and then sliced according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com