Phase change energy storage capsule and preparation method thereof

A phase-change energy storage and capsule technology, which is applied in the field of phase-change energy storage capsules and its preparation, can solve the problems of hindering the volume expansion of the core material, the phase change cannot be realized smoothly, and it is difficult to carry out actual production, so as to reduce the temperature of the wall Decrease range, increase room comfort, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

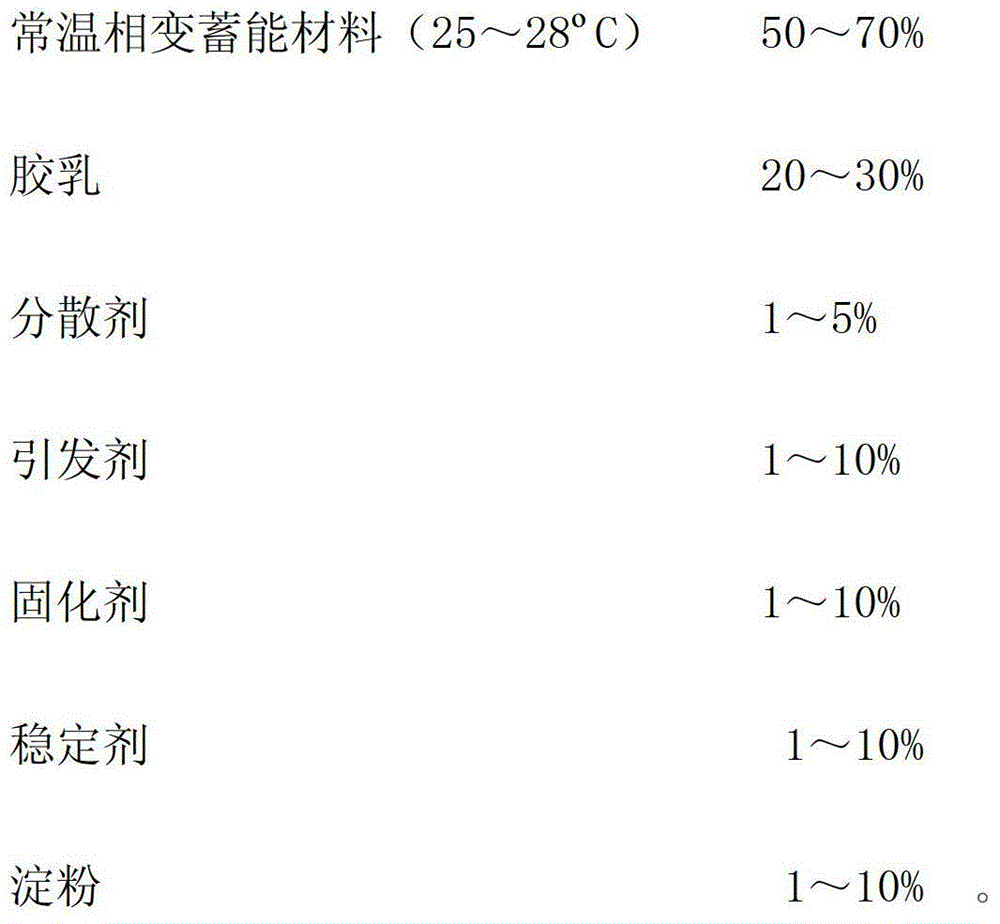

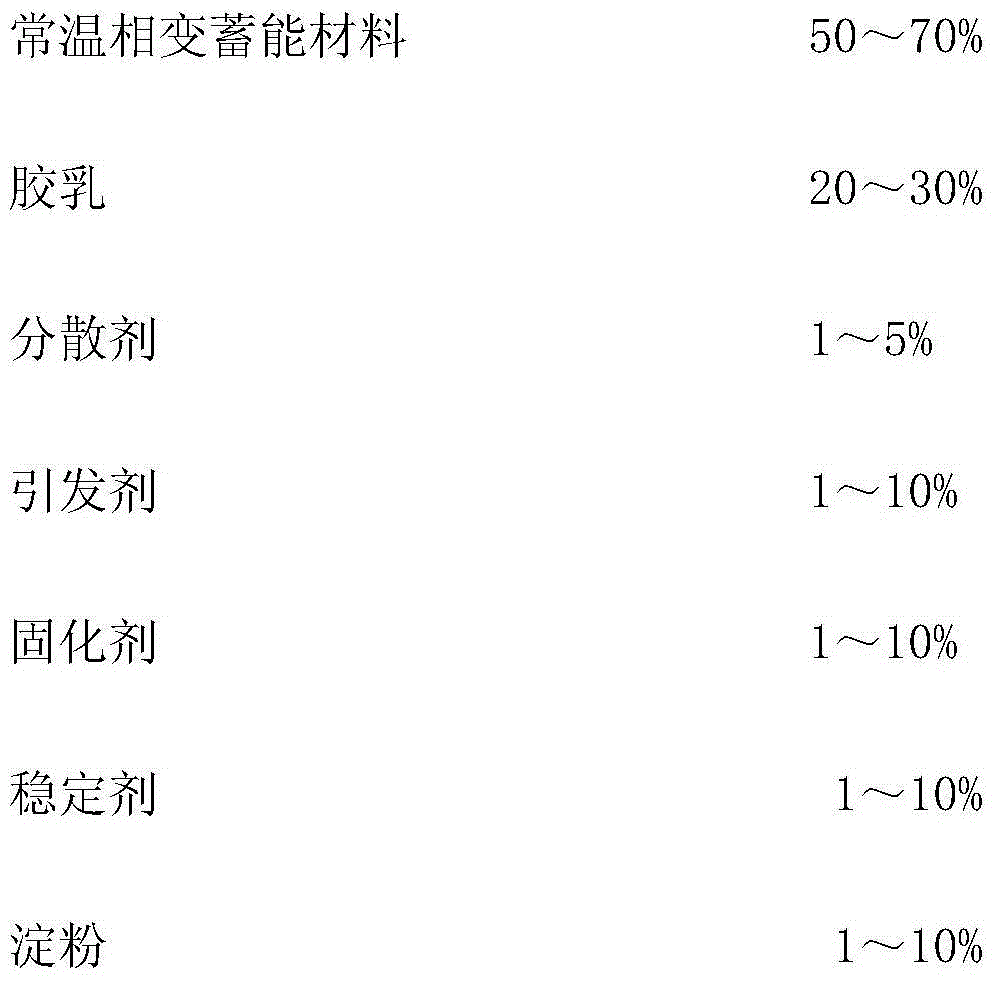

Method used

Image

Examples

Embodiment 1

[0025] The proportion and dosage of ingredients are: 100kg of normal temperature phase change energy storage material; 50kg of styrene-butadiene latex; 10kg of 10% NF (naphthalenesulfonic acid formaldehyde condensate sodium salt); 5kg of 10% ammonium persulfate solution; 6kg of 5% aluminum sulfate solution; Zinc oxide, stearic acid, deionized water, 27kg of slurry mixed according to the mass ratio of 3:1:4, referred to as zinc grease slurry; starch 2kg.

[0026] (1) Take the phase change energy storage material at room temperature, process it into 2-5mm particles with a screw extruder, and store it below 20°C for later use.

[0027] (2) Add styrene-butadiene latex to the reaction kettle, add NF, ammonium persulfate solution, and zinc fat slurry, adjust the speed to 200rpm, and stir for 30min.

[0028] (3) Add phase change energy storage particles, adjust the temperature to 20-23°C, adjust the speed to 100rpm, spray the aluminum sulfate solution, stir for 15 minutes, spray the ...

Embodiment 2

[0032] The proportion and dosage of ingredients are: 120kg of normal temperature phase change energy storage material; 50kg of styrene-butadiene latex; 2.5kg of 40% sodium dodecylbenzenesulfonate; 2.5kg of 20% ammonium persulfate solution; , stearic acid, deionized water, 21kg of slurry mixed according to the mass ratio of 3:1:3, referred to as zinc lipid slurry; starch 2kg.

[0033] 1. Take the phase change energy storage material at room temperature, process it into 2-5mm particles with a screw extruder, and store it below 20°C for later use.

[0034] 2. Add styrene-butadiene latex to the reaction kettle, add sodium dodecylbenzenesulfonate, ammonium persulfate, and zinc grease slurry, adjust the speed to 200rpm, and stir for 30min.

[0035] 3. Add phase change energy storage particles, adjust the temperature to 20-23°C, adjust the speed to 100rpm, spray the aluminum sulfate solution, stir for 15 minutes, spray the aluminum sulfate solution, continue stirring for 30 minutes, ...

Embodiment 3

[0039] The proportion and dosage of ingredients are: 140kg of normal temperature phase change energy storage material; 40kg of epoxy rubber latex; 2kg of 40% sodium dodecylbenzenesulfonate; 2kg of 30% hydrogen peroxide solution; 2kg of 20% aluminum sulfate solution; , stearic acid, deionized water, 12kg of slurry mixed according to the mass ratio of 3:1:3, referred to as zinc lipid slurry; starch 2kg.

[0040] 1. Take the phase change energy storage material at room temperature, process it into 2-5mm particles with a screw extruder, and store it below 20°C for later use.

[0041] 2. Add epoxidized rubber latex to the reaction kettle, add NF, hydrogen peroxide, and zinc grease slurry, adjust the speed to 200rpm, and stir for 30min.

[0042] 3. Add phase change energy storage particles, adjust the temperature to 20-23°C, adjust the speed to 100rpm, spray the aluminum sulfate solution, stir for 15 minutes, spray the aluminum sulfate solution, continue stirring for 30 minutes, spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com