Multifunctional pesticide fertilizer and production method thereof

A production method and multifunctional technology, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of affecting the efficacy and fertilizer efficiency of medicinal fertilizers, and low utilization rates of pesticides and fertilizers, so as to improve the emergence rate, increase water content, The effect of promoting plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

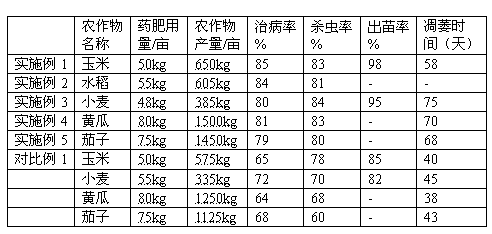

Examples

Embodiment 1

[0028] Weigh the raw materials:

[0029] Abamectin 0.1kg;

[0030] Urea fertilizer 20 kg;

[0031] Ammonium dihydrogen phosphate fertilizer 20 kg;

[0032] Potassium sulfate fertilizer 20kg;

[0033] Ammonium molybdate tetrahydrate fertilizer 0.5kg;

[0035] Boron mud 10kg.

[0036] Crush the boron mud to 30 mesh according to the above weight, add abamectin and mix well, add starch grafting, then add urea, ammonium dihydrogen phosphate and potassium sulfate fertilizer and ammonium molybdate tetrahydrate fertilizer and mix evenly, using discs Granules, making multifunctional medicine fertilizer.

Embodiment 2

[0038] Weigh the raw materials:

[0039] Polyoxin 2.5kg;

[0040] Abamectin 2.5kg;

[0041] Ammonium dihydrogen phosphate fertilizer 20kg;

[0042] Potassium sulfate fertilizer 20kg;

[0043] Ammonium molybdate tetrahydrate fertilizer 2kg;

[0044] Zinc sulfate fertilizer 2kg;

[0046] 15kg of magnesium ore waste residue.

[0047] Crush the magnesium ore waste residue to 150 mesh according to the above weight, add abamectin and polyoxin and mix evenly, add starch grafting, and then add ammonium dihydrogen phosphate and potassium sulfate fertilizers, ammonium molybdate tetrahydrate and zinc sulfate fertilizers Mix uniformly and use extrusion granulation to make multifunctional fertilizer.

Embodiment 3

[0049] Weigh the raw materials:

[0050] Polyoxin 4.5kg;

[0051] Abamectin 4.5kg;

[0052] Ammonium dihydrogen phosphate fertilizer 20kg;

[0053] Ammonium molybdate tetrahydrate fertilizer 2kg;

[0054] Zinc sulfate fertilizer 1kg;

[0055] Starch grafting 5kg;

[0056] Magnesium ore waste residue 20kg.

[0057] Crush the magnesium ore waste residue to 300 mesh according to the above weight, mix abamectin and polyoxin evenly, add starch grafting, and then add ammonium dihydrogen phosphate fertilizer, ammonium molybdate tetrahydrate and zinc sulfate fertilizer and mix evenly. Disc granulation to make multifunctional medicine fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com