Method for enhancing humidifying property of zeolite through microwave auxiliary ammonium chloride

A microwave-assisted, ammonium chloride technology, applied in the direction of crystalline aluminosilicate zeolite, can solve problems such as few reports, and achieve the effects of fast moisture absorption and desorption, rich pores, and favorable diffusion and adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

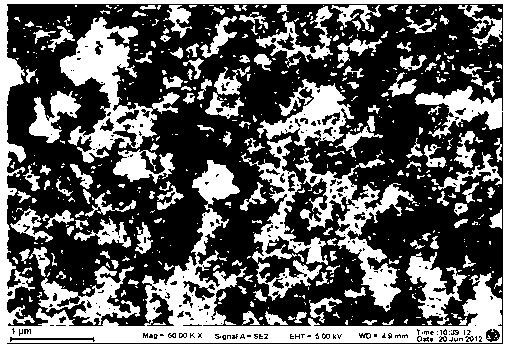

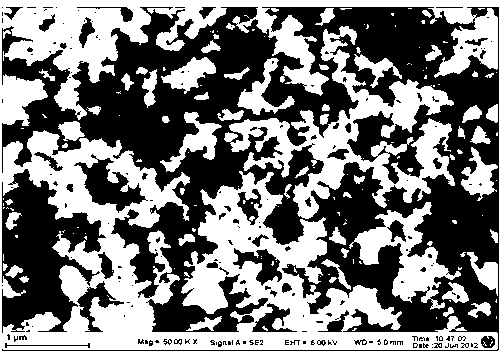

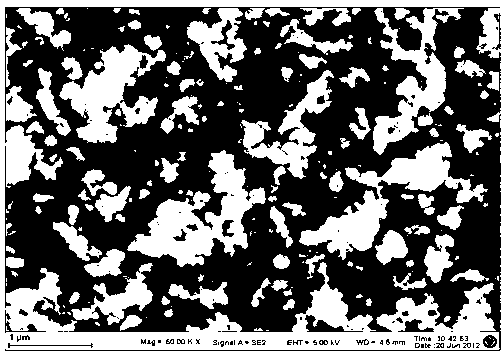

Image

Examples

Embodiment 1

[0021] 1) Grind the natural zeolite to 100-120 mesh, put it in a drying vessel, put it in an oven for drying, set the oven temperature at 80°C, and use it as a zeolite sample after drying for 6 hours, and weigh it accurately with an electronic balance The zeolite sample is packed in a non-metallic box, placed in a microwave field with uniform density, and heated with 100W microwave for 1min to obtain a primary modified zeolite sample;

[0022] 2) Add the primary modified zeolite sample to the ammonium chloride solution with a mass percentage concentration of 1% at a mass ratio of zeolite to solution of 1:3, and place the mixture in a non-metallic box. Place it in a microwave field and heat it with 100W microwave for 1min to obtain a secondary modified zeolite sample;

[0023] 3) Take the secondary modified zeolite sample, wash it, and dry it to prepare a new type of microwave-assisted ammonium chloride modified zeolite material

Embodiment 2

[0025] 1) Grind the natural zeolite to 100-120 mesh, put it in a dry container, put it in an oven for drying, and set the temperature of the oven at 90°C, and use it as a zeolite sample after drying for 7 hours, and accurately weigh it with an electronic balance The zeolite sample is placed in a non-metallic box, placed in a microwave field with uniform density, and heated with 200W microwave for 3 minutes to obtain a primary modified zeolite sample;

[0026] 2) Add the primary modified zeolite sample to the ammonium chloride solution with a mass percentage concentration of 3% at a mass ratio of zeolite to solution of 1:5, and place the mixture in a non-metallic box. Place it in a microwave field and heat it with 200W microwave for 3 minutes to obtain a secondary modified zeolite sample;

[0027] 3) Take the secondary modified zeolite sample, wash it, and dry it to prepare a new type of microwave-assisted ammonium chloride modified zeolite material.

Embodiment 3

[0029] 1) Grind the natural zeolite to 100-120 mesh, put it in a drying vessel, put it in an oven for drying, set the oven temperature at 100°C, and use it as a zeolite sample after drying for 8 hours, and accurately weigh it with an electronic balance The zeolite sample is packed in a non-metallic box, placed in a microwave field with uniform density, and heated by 300W microwave for 6 minutes to obtain a primary modified zeolite sample;

[0030] 2) Add the primary modified zeolite sample to the ammonium chloride solution with a mass percent concentration of 6% at a mass ratio of zeolite to solution of 1:5, and place the mixture in a non-metallic box. Place it in a microwave field and heat it with 300W microwave for 6 minutes to obtain a secondary modified zeolite sample;

[0031] 3) Take the secondary modified zeolite sample, wash it, and dry it to prepare a new type of microwave-assisted ammonium chloride modified zeolite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com