Environment-friendly glue free particle board and preparation method thereof

An environment-friendly particle board technology, which is applied to flat products, manufacturing tools, and other household appliances, can solve the problems of endangering human health, consuming petroleum resources, and high prices, and achieves improved strength and water resistance, and a wide range of applications. The effect of the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

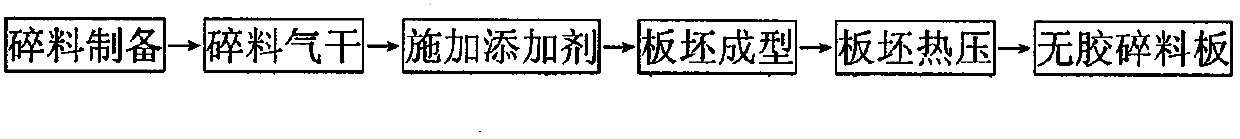

Method used

Image

Examples

Embodiment 1

[0027] (1) Sucrose, citric acid, acetic acid and water are formulated into a composite additive solution in a weight ratio of 30:10:10:50.

[0028] (2) Chip the wood, spray water to adjust the moisture content to about 60%, process it into pieces with a ring planer, and dry it naturally to reach the air-dried moisture content (10-12%)

[0029] (3) A certain amount of crushed material is weighed, and then the composite additive solution is evenly sprayed on the surface of the crushed material, and the solid application amount of the composite additive accounts for 15% of the weight of the dry crushed material.

[0030] (4) Lay the additive-added scrap material into a single-layer slab of a certain width, and after pre-pressing, send it to a hot press for hot pressing, and press it into a glue-free particle board. The hot pressing temperature is 180°C, the pressure is 3-5MPa, and the time is 10 minutes (the plate thickness is 12mm).

Embodiment 2

[0032] (1) Sucrose, citric acid, acetic acid and water are formulated into a composite additive solution in a weight ratio of 20:20:10:50.

[0033] (2) Naturally dry the bagasse to the air-dried moisture content (10-14%)

[0034] (3) Weigh a certain amount of bagasse scraps, and then evenly spray the composite additive solution on the surface of the scraps, and the solid application amount of the composite additives accounts for 10% of the weight of the dry scraps.

[0035] (4) Lay the additive-applied crushed material into a single-layer slab of a certain format, and after pre-pressing, send it to a hot press for hot pressing, and press it into a glue-free particle board. The hot pressing temperature is 180°C, the pressure is 3-5MPa, and the time is 7 minutes (the plate thickness is 7mm).

Embodiment 3

[0037] (1) Sucrose, citric acid, acetic acid and water are formulated into a composite additive solution in a weight ratio of 25:15:10:50.

[0038] (2) Cut the hemp stalks into pieces, use a planer to make scraps, and dry naturally until the air-dried moisture content (10-13%)

[0039] (3) Weigh a certain amount of crushed hemp stalks, and then evenly spray the composite additive solution on the surface of the crushed materials. The solid application amount of the composite additive accounts for 16% of the weight of the dry crushed materials.

[0040] (4) Lay the additive-applied scrap material into a single-layer slab of a certain format, and after pre-pressing, send it to a hot press for hot pressing, and press it into a glue-free particle board. The hot pressing temperature is 190°C, the pressure is 3-5MPa, and the time is 7 minutes (the plate thickness is 8mm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com